News

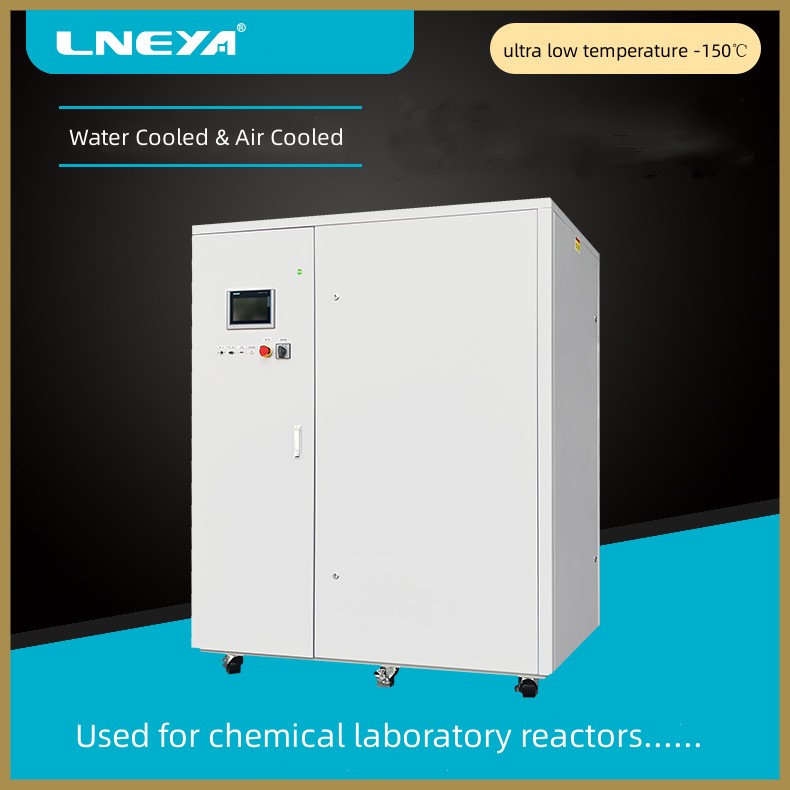

Selection of ultra-low temperature chiller supporting the glass reactor

In order to achieve an economical ultra-low temperature environment for glass reactors, many customers will not choose multi-stage compressor refrigeration equipment with more than two stages, but use liquid nitrogen. The cost of liquid nitrogen is low, and this refrigeration method is welcomed by some users, both in experiments and in production. However, due to the low boiling point of liquid nitrogen (minus 195.8°C), the latent heat is small and it is easy to evaporate. There are also bi...

View details

Cooling method for laboratory evaporative instruments in operation

Choosing the right cooling method for an evaporation experiment can have an unimaginable impact on overall system performance, economy, and efficiency. It is necessary to purchase cooling water circulation machine as supporting equipment. When purchasing a suitable cooling water circulator, important factors to consider include: 1. Minimum condensing temperature and corresponding cooling capacity; 2. Circulating pressure; 3. Circulating flow rate; 4. Suitable accessories. When selecting and ...

View details

KRY series water chiller for new energy vehicle quality test

The new energy vehicle powertrain test bench can be directly connected to the power output end of the electric drive assembly through the half-shaft. The front end is equipped with high-precision torque sensor and speed sensor to provide high-precision measurement data in the industry. The tested object is the integrated structure of motor and reducer (including differential). The installation of special chillers for new energy testing is an important link before operation, and the quality o...

View detailsNew energy vehicle quality test water cooling chiller simulation equipment

It is mainly used in the water cooling system stability test of new products such as electric drives, motors, reducers, and charging piles of new energy vehicles. Constant temperature, constant pressure and constant current heat test (5-85°C), high and low temperature operation test (-40-150°C), motor cooling water test (5-30°C) and other cooling tests. Applications include electric vehicles, hybrid vehicles, aerospace and scientific research. It can realize heating and cooling output, and ...

View details

Effect of Temperature on Reactions of Chemical Organic Synthesis

Organic synthesis is a common chemical phenomenon in chemistry. Temperature has an important influence on it during the whole synthesis process. As the temperature rises, the heat-absorbing reaction will speed up, resulting in a significant change in the equilibrium constant; once the temperature decreases, The exothermic reaction will be accelerated. Endothermic and exothermic, as the main characteristics of organic synthesis reactions, need to be paid enough attention to by researchers in t...

View detailsPoints for attention in the selection of industrial heating and cooling machines

In food factories, pharmaceutical factories, biology, new material processing, and chemical plants, the raw materials in the reactor need to be cooled rapidly during the industrial production process involved in the reactor. In order to achieve the purpose of rapid cooling, it is necessary to directly cool down the reactor, so as to achieve the purpose of indirectly reducing the temperature of the material in the reactor. At present, there are about three temperature control schemes for tempe...

View details

Heat transfer oil for cooling and heating temperature control systems in the chemical and pharmaceut

The cooling and heating temperature control system, also known as a high and low temperature circulator or dynamic temperature control system, is a temperature control equipment used in the pharmaceutical and chemical industry to provide cold and heat sources for supporting reaction kettles. The LNEYA cooling and heating temperature control system uses heat transfer oil as the heat transfer medium. Depending on the temperature range and model of the equipment, different types of heat transfer...

View details

The importance of constant temperature equipment in oil bath heating systems

The constant temperature equipment of the oil bath heating system is used for dynamic temperature control of fluid cooling and heating with heat conducting medium, which is applied to high-precision industries such as pharmaceuticals, chemicals and semiconductors, and helps customers complete temperature control of the process. It is equipped with biochemical experimental equipment such as reactors, distillation, evaporators, and Rotary evaporator to control the cooling and heating of heat c...

View details

Precautions for purchasing reactor temperature control system

The reactor temperature control system is applied in the reaction tank for cooling, heating, and temperature control. It has the function of providing low and high temperatures, and can meet the different needs of different customers. Therefore, what should everyone pay attention to when purchasing? 1. Before purchasing, everyone should pay attention to the temperature control status, model, structure, material specifications, capacity, power factor, after-sales service, etc. of the reaction...

View details

The reason why the cooling thermostat Chiller suddenly fails to start

If there are any unexpected situations during the use of the cooling thermostat Chiller, it is important to promptly identify the specific reasons before resolving them, in order to effectively address various issues. For example, what is the reason why the cooling thermostat Chiller suddenly fails to start during operation? One、 The reason why the cooling thermostat Chiller cannot start 1. The main reason is that during the operation of the system, the pressure at the equipment inlet is l...

View details LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -