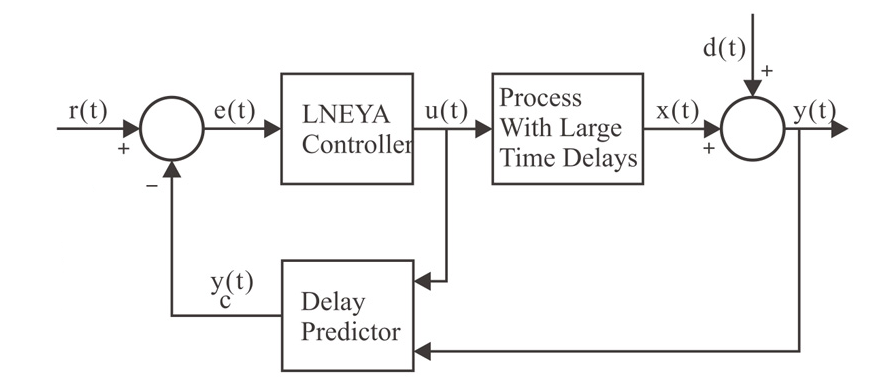

Dynamic temperature control

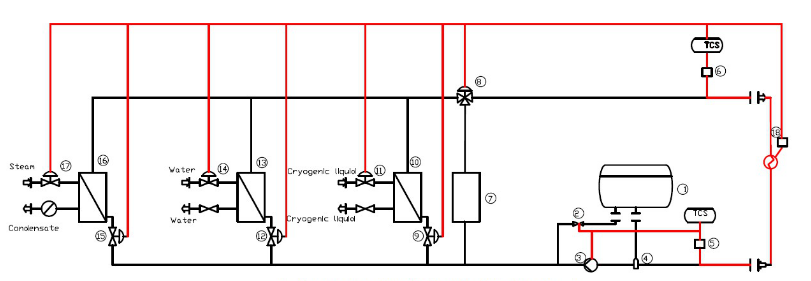

such as reactions

Some biochemical reactions need to cycle between high and low temperatures repeatedly.Accept customization

Test equipment guarantee

such as Mechanical cooling

Overheating of equipment will accelerate aging and even fire, affecting the service life of the equipment.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier