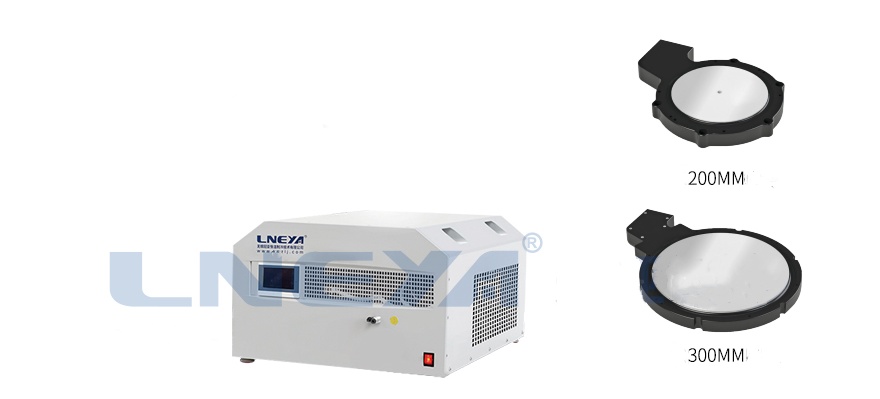

Thermal Chuck or Thermal Plate/Thermal Control Unit

MD -75℃~225℃- Temperture accuracy±0.1℃

- Heating Power-60°C to +25°C: 2 min 0°C to +25°C: 2 min +25°C to +220°C: 6 min

- Cooling Power220°C to +25°C: 2 min +25°C to -60°C: 6 min

- Source Power2.8KW

- Flat ShapeRound/Square

Quick temperature change control chuck

-75℃ to 225°C

|

Model |

MD-708 |

MD-712 |

MDL-708 |

|

Temp. Range |

-75℃~225℃ |

-75℃~225℃ |

-75℃~225℃ |

|

Temperature control accuracy |

±0.1℃ |

±0.1℃ |

±0.1℃ |

|

temperature uniformity |

±1℃ |

±1℃ |

±1℃ |

|

Flatness |

±50um |

±50um |

±50um |

|

Tablet Size |

200mm diameter disc |

300mm diameter disc |

150mm*200mm |

|

Host and card cable |

2.5m (other lengths can be customized) |

||

|

Flat surface treatment |

Electroplated nickel (optional gold plating) |

||

|

Heat Up |

-60°C to +25°C: 2 min 0°C to +25°C: 2 min +25°C to +220°C: 6 min |

||

|

Cool Down |

220°C to +25°C: 2 min +25°C to -60°C: 6 min |

||

|

Control System |

PLC controller, heating feed-forward PID fuzzy algorithm, cooling electronic expansion valve PID adjustment control cooling capacity |

||

|

Display and Record |

7-inch color touch screen, record temperature curve |

||

|

Communication |

Ethernet interface TCP/IP protocol |

||

|

Refrigeration Compressors |

Taikang |

||

|

Power Supply |

220V 50/60HZ 2.8KW |

220V 50/60HZ 4.5KW |

220V 50/60HZ 2.8KW |

|

Host size mm |

550×650×370 |

550×650×370 |

550×650×370 |

Product Description

MD’s greatest innovation in thermal testing is the series of thermally controlled chucks, which are mainly used for performance testing, modeling, process development, design defect or IC failure analysis of semiconductor wafers. It can realize rapid temperature change and precisely control the temperature. The system itself has its own refrigerator, which avoids the consumption of liquid nitrogen, carbon dioxide, etc., and each system includes a chuck and a cold and hot control unit.

The inside of the plate adopts the direct evaporation method of refrigerant, which greatly improves the heat exchange efficiency and the heat exchange power per unit area of the plate compared with the liquid cooling method.

Rapid cooling/heating rates up to 25°C/min

Built-in refrigerator to avoid the consumption of liquid nitrogen, carbon dioxide, etc. Programmable automation, temperature stability +/-0.1℃

Controller provides touch screen and remote interface to precisely control and monitor equipment temperature

Display test status – real-time data

Thermal Chuck MD series provides an open flat surface working platform, rapid temperature rise and fall, and constant temperature control, which can be used for testing RF devices and high-density power devices (IGBTSAND MOSFETS), and can also be used for rapid cooling of laboratory flat panels (plasma, biological products, batteries), etc.

Email: sales@cnzlj.com

WhatsApp: 086 13912479193

Related recommendations

-

The difference between direct contact liquid cooling and cold plate liquid cooling technology

1948The cold plate liquid cooling technology is an implementation method in which the heat of the heating components is indirectly transferred to the cooling liquid enclosed in the circulating pipeline through the cold plate, and the heat is...

View details -

KRY Direct Cooling Heating Series

3689Rated test conditions: dry bulb temperature 20℃; wet bulb temperature 16℃. Inlet water temperature 20℃; outlet water temperature 25℃. The data in this table is for reference only. Please refer to the unit name...

View details -

AI Series

2661* 1. Widely used in high and low temperature testing of semiconductor equipment.Cold and heat source of electronic equipment at high temperature and low temperature; 2. Independent refrigeration circulating air ...

View details -

ZLJ Series

3208Multiple control requirements can be achieved by merging multiple devices into a larger cabinet Used for small heat exchange area and large heat exchange capacity The product directly outputs and...

View details -

-

LTS -40℃~80℃

2217It is widely used in the semiconductor manufacturing process to control the temperature of the reaction chamber, the temperature of the heat sink, and the temperature control of the non-flammable fluid of the heat transfer...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier

Submit for consultation

We will reply to you within 24 hours