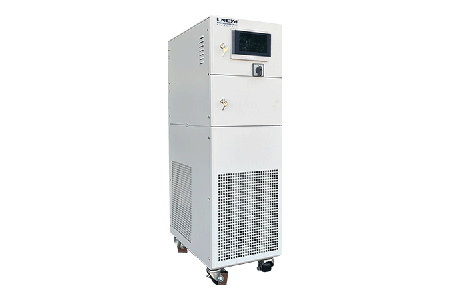

CHILLERS

For Biochemical Pharmaceutical : Crystallization, Synthesis, Extraction…

Vacuum Chamber, Semiconductor Etching, Deposition, Oxidation…

Temperature Range -100℃~135℃

Temperature Accuracy ±0.5℃

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier