Search the whole station

SOLUTION

FLTZ Frequency Conversion Series

—Temperature control accuracy ±0.05℃ (Outlet temperature steady state)

-90~+100℃, mainly used for precise temperature control in semiconductor production and testing processes. The company applies a variety of algorithms in the system to achieve fast system response and high control accuracy.

LTZ Variable Frequency Series

—Adopt frequency conversion technology, high efficiency and energy saving

Adopt frequency conversion technology to achieve high efficiency and energy saving. The variable frequency compressor unit changes the operating speed of the DC compressor at any time according to the user’s cooling and heating load requirements through the built-in frequency conversion device, thereby avoiding the compressor and electric heating full load confrontation, maintaining a stable working state of the unit and achieving energy-saving effects.

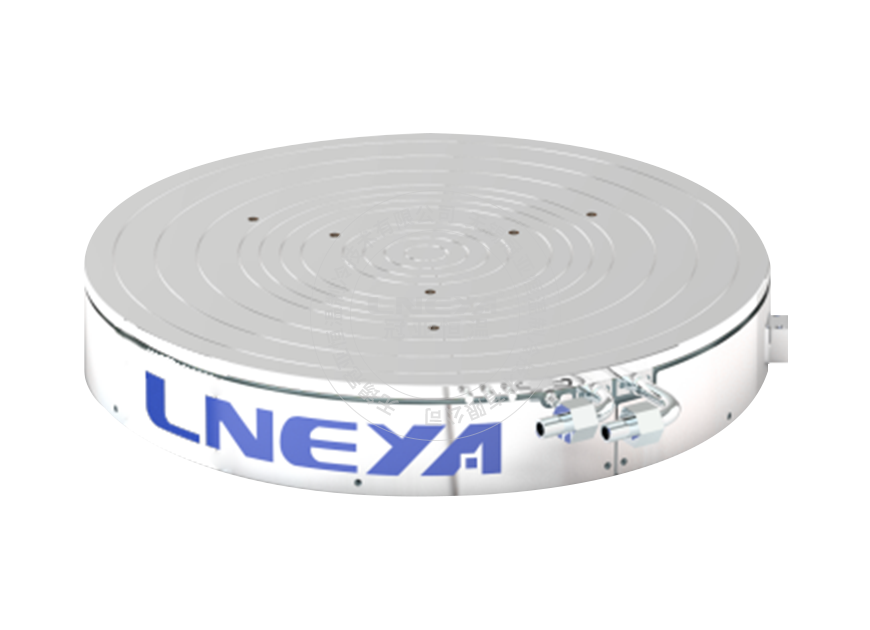

Thermal / Vacuum chuck

— 8-inch and 12-inch vacuum chucks and non-standard customized square cold plates

LNEYA supporting a temperature range of -70℃~+200℃, and can also customize various other temperature ranges, built-in multiple temperature sensors, multi-zone temperature control, precise FID adjustment and temperature control; supports direct cooling, liquid cooling, and air cooling.

Heat Exchange Chiller ETCU

—No compressor

ETCU compressor-free heat exchange system, the system can be universal expansion tank, condenser, cooling water system, etc., which can effectively reduce the size of equipment and reduce the number of operating steps.

Thermal Probe

—Chip design, chip production process testing

Supports rapid heating and cooling from extremely low temperatures to high temperatures. The fastest rate can reach 50’C/min. It can accurately control the temperature, and the error is usually within +0.2℃.

ZLTZ Heat Exchange Chillers

—Highly efficient heat exchange, automatic recovery of heat transfer medium

ZLTZ temperature control unit is combined with a microchannel reactor to achieve high exothermic temperature control. Under the same flow rate conditions, the heat transfer efficiency is more than five times that of thermal oil heat exchange and temperature control. At the same time, the inlet and outlet temperature difference is small, and the temperature field is highly uniform, making it particularly suitable for applications with violent exothermic reactions.

ZLJ Direct low temp chillers

—Can be used for gas capture

The refrigerant in the refrigeration system is directly transferred to the target control element (heat exchanger) for heat exchange, thereby cooling the target control object. This system has a heat exchange capacity that is typically more than five times greater than that of a fluid (gas) being transferred to a heat exchanger. This makes it particularly suitable for applications where the heat exchanger has a small heat exchange surface but a high heat transfer capacity.

Rapid Temp Change Test Chamber

—Fast temperature change, fast heating and cooling rate

Applicable to environmental stress screening test, through environmental stress screening of products, accelerate the discovery of product design defects and improve product reliability. Many industries have realized that high-speed temperature change cycle testing can identify unreliable systems that have already entered the production test stage. It has become a standard method for improving quality and effectively extending the normal working life of products.

Chip Aging Test Chamber

—Applicable for semiconductor PCB aging testing

By precisely controlling environmental parameters such as temperature and humidity, we simulate extreme conditions such as high temperature, high humidity, and high stress that chips may encounter in actual use, accelerating the chip aging process. In this way, we can screen out early-failed chips in a short period of time, optimize design solutions, and improve product yields.

LQ series

—Low temperature can reach -110℃

Applied to cool down the gas (non-corrosive): when dry compressed air, nitrogen, argon and other normal temperature gases are introduced into the LQ series equipment, the outgoing gas can reach the target low temperature and be supplied to the components or heat exchangers to be tested.

AES Thermal Stream

—Fast heating and cooling rate, +150℃~-55℃ in less than 10S

Provides accurate and rapid ambient temperature readings for chips, modules, integrated circuit boards, electronic components, etc. It is an instrument for product electrical performance testing, failure analysis, and reliability assessment.

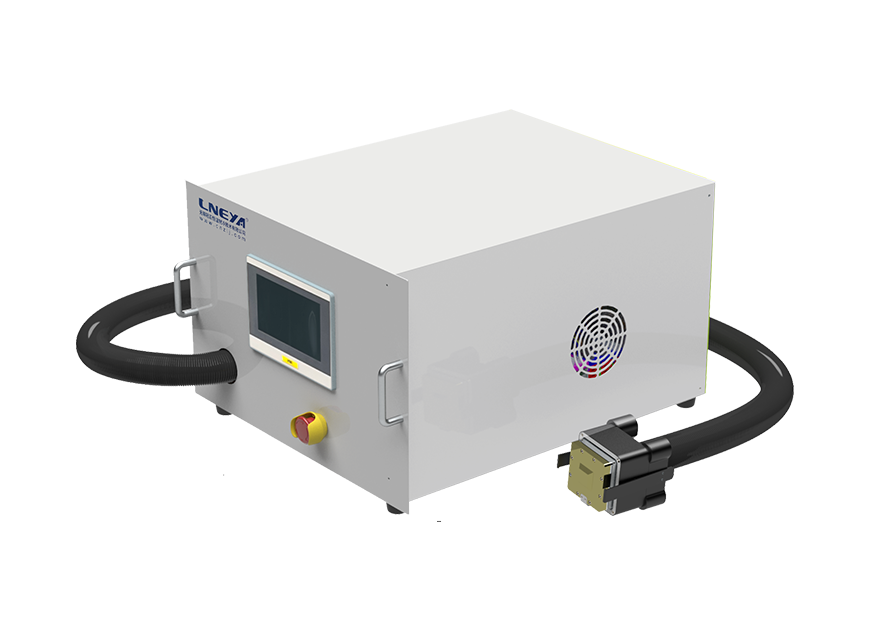

AET Themal Test System

—Optional control of outlet gas temperature and process target temperature

Compressed air enters the gas rapid temperature change tester, which has a built-in desiccant to pre-dry the gas to a dew point below -70 degrees Celsius. Cooling and heating temperature control are then applied to output gas at a stable flow rate, pressure, and constant temperature. This temperature control is performed on target objects (such as various temperature-controlled chucks, cavity environments, heat plates, material shuttles, cavities, electronic components, etc.). The process temperature is controlled using a temperature sensor on the remote chuck, automatically adjusting the output gas temperature.

AI Cooling Circulation Unit

—Circulating air high and low temperature constant temperature test

Used in high and low temperature testing of semiconductor equipment. It provides a heat source for high and low temperature constant temperature testing of electronic equipment. It has an independent refrigeration cycle fan unit and can operate continuously for long periods of time, with automatic defrosting, and the defrosting process does not affect the storage temperature.

Industrial Gas Dryer

—Low dew point drying and cleaning

It is used in sensors, semiconductor manufacturing, film and packaging material licensing, powder material transportation, spraying systems, food industry, pharmaceutical industry, etc., which require a distributed air source with a low dew point of -80℃ and cleanliness.

Negative pressure type chiller

—Achieve temperature fluctuation ≤±0.3℃

Precise temperature control is achieved through fluid circulation in a negative pressure environment. Working principle: A negative pressure generator drives the heat transfer medium (water/oil) to circulate, eliminating the risk of leakage. Suitable for cooling various types of boards.