Search the whole station

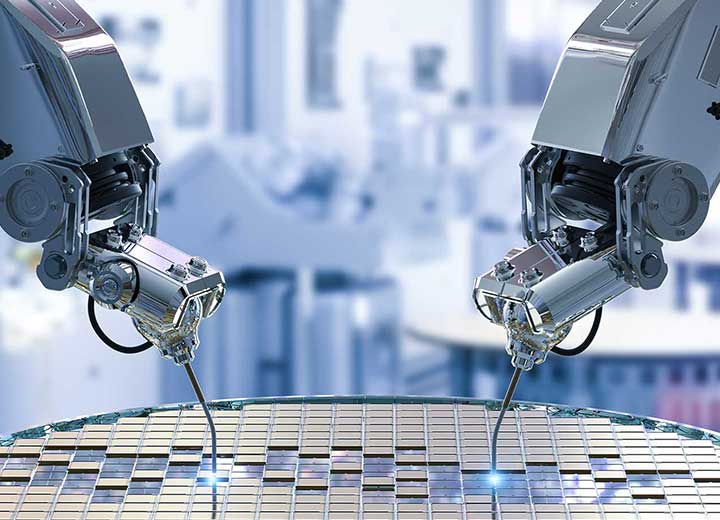

Reliable Cooling Solutions for Wafer Processing, Testing, and Packaging

Temp range -100℃~90℃ Temp accuracy ±0.1℃

The semiconductor industry demands extremely accurate temperature control. Many fabrication and testing steps are highly sensitive to even small temperature changes. Product performance and yield depend on stable, high-precision cooling systems.

LNEYA is a leading manufacturer of advanced chillers for semiconductor applications. Since 2010, we have supplied reliable temperature control equipment for wafer processing, packaging, and testing lines. Our product range includes both standard and customized chillers designed for precise, repeatable performance.

For specialized processes, we can tailor a cooling solution to your requirements in temperature range, capacity, and control interface.

Contact our engineering team to request a product catalog or get a quote for your semiconductor cooling system.

Semiconductor manufacturing demands stable and precise cooling systems. A reliable semiconductor chiller helps control temperature during wafer processing, etching, and testing. At LNEYA, we design semiconductor chillers with high temperature accuracy, wide range operation, and reliable long-term stability.

Semiconductor manufacturing requires extremely stable environmental conditions. Even a small temperature drift can affect product yield and device reliability. A semiconductor chiller provides precise temperature control during critical process steps such as wafer packaging, testing, and fabrication.

These chillers are widely used for process cooling in semiconductor fabs and metrology systems. They help stabilize CMOS and CCD sensors, maintain temperature in AOI inspection systems, and provide independent cooling for chamber walls during plasma etching or thin-film deposition.

In applications such as thermal atomic layer etching of metal tungsten, consistent cooling ensures repeatable results and longer equipment life.

Leading Semiconductor chiller manufacture in China

Since our founding in 2010, we have served over 30,000 customers and hold over 130 patents. Our chillers are selected by over 100 university laboratory projects worldwide and exported to over 20 countries, with agents in the United States, Canada, Australia, Russia and South Korea. All LNEYA products go through a rigorous 3-step quality control process to ensure the highest quality: visual inspection, performance testing and electrical safety testing. We provide our customers with comprehensive after-sales service and technical support. Let us be your partner!

TEL:

EMAIL:

WeChat & WhatsApp:

Fill out the form and our team will contact you shortly.