KRYO 0℃~160℃

Oil Cooling Chiller- Temperature accuracy±0.3℃

- Flow Accuracy±0.2L/min

- Cooling Capacity12kW~38kW

- Heating Capacity15kW~38kW

- Flow rate output1~40 L/min

- CoolantOil

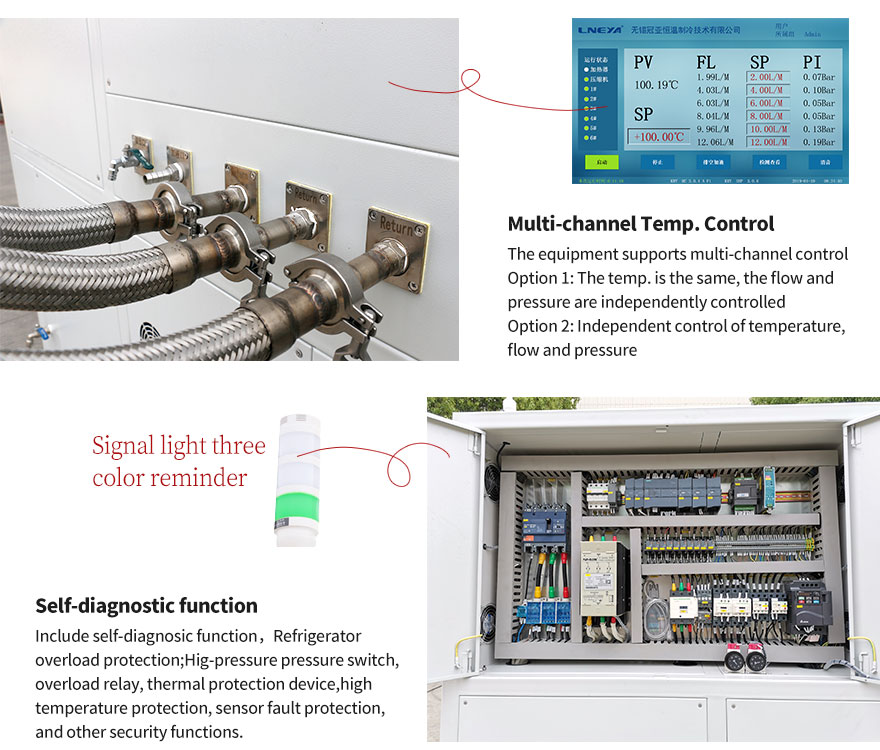

Cooling and heating temperature and flow control

The object under test is connected to a test platform adapter

The component is cooled and heated by ethylene glycol water solution

-40’C~100°C (expandable to 150°C)

- Color touch screen

- Equipment power switch

- Liquid level light

- High and low pressure gauges

- Communication interface

- Four-way casters

- Circulation pipeline

- Electrical cabinet

- Compressor circulation pump

| KRYO SERIES | A15W | A25W | A38W | A15W2S | A25W2S | A38W2S | |

| Temperature range | 0℃ ~ +160℃ Different viscosity oils have different temperature ranges | ||||||

| Temperature control accuracy | ±0.3℃ | ||||||

| Temperature feedback | PT100 | ||||||

| Flow control | 2L/min~20L/min, one in and one out, in and out control linkage | 2L/min~15L/min Two outputs, one input Flow control linkage | |||||

| Flow accuracy | ±0.2L/min | ||||||

| Pressure control | 0.2bar~2.5bar | ||||||

| Heating capacity kW | 15 | 25 | 38 | 15 | 25 | 38 | |

| Cooling capacity kW | 125℃ | 15 | 25 | 38 | 15 | 25 | 38 |

| 20℃ | 12 | 20 | 30 | 12 | 20 | 30 | |

| Compressor | Emerson Copeland Scroll Flexible Compressor/Japanese Scroll Flexible Compressor | ||||||

| Throttling method | Electronic expansion valve | ||||||

| Evaporator | Plate Heat Exchanger | ||||||

| Circulation pump | Gear Pumps | ||||||

| Flow regulation | Inverter vector control | ||||||

| Input, Display | 7-inch color touch screen/PLC controller | ||||||

| Communications | CAN communication | ||||||

| Refrigerant | R410A | ||||||

| Coolant | Oil | ||||||

| Liquid inlet and outlet | G3/4 | ||||||

| Cooling water @20℃ | 3000L/H | 4200L/H | 6200L/H | 3000L/H | 4200L/H | 6200L/H | |

| Cooling water connection | G3/4 | G3/4 | G1 | G3/4 | G3/4 | G1 | |

| power supply | 380V 50HZ three-phase five-wire | ||||||

| Breaker | 50A | 80A | 125A | 50A | 80A | 125A | |

| External tooling | External oil return tooling size 600×850×600 | ||||||

| If the external oil return fixture is selected, the fixture needs to be installed under the test motor. | |||||||

Descriptions

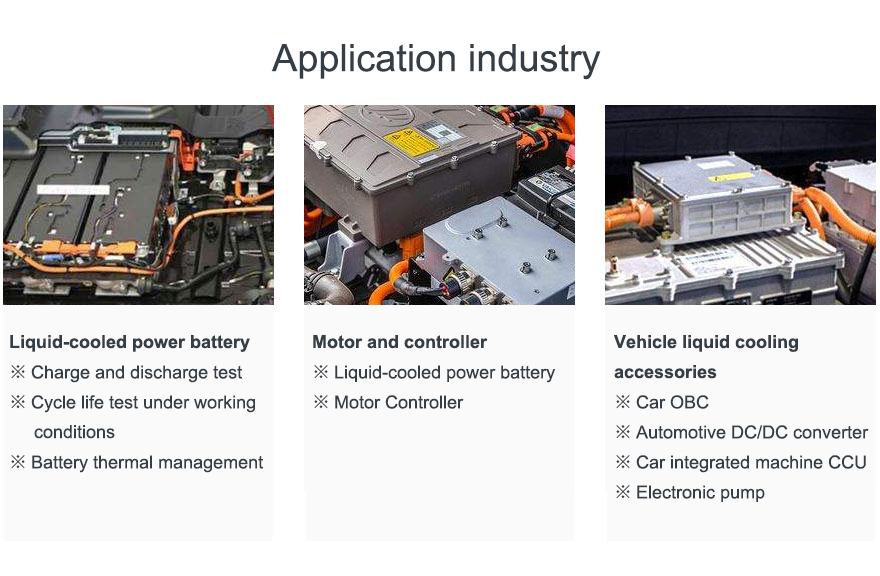

For the power battery charging management, the precision temperature control device for testing the permanent magnet synchronous motor, the switched reluctance motor, the asynchronous motor and its controller can realize the local + remote control mode through the liquid crystal controller panel;

With automatic fault protection function, it can output corresponding signals to ensure the safety of equipment. The main parts are all international brands, quality assurance, high-pressure electrostatic spray treatment on the surface, and auxiliary equipment can be added according to specific needs.

recommend products

KRY -40℃~+100℃ (1to6)

The components are cooled and heated internally through ethylene glycol aqueous solution for testing -40 ° C~100 ° C (expandable to 150 ° C) For the power battery charging management, the precision …

KRY -40℃~+100℃ (1to1)

Refrigeration, heating, temperature control, flow control Connect the tested object to a testing platform adapterThe components are cooled and heated internally through ethylene glycol aqueous solution for testing. …

KRY -40℃~+100℃ (1to2)

Temperature range is -40℃~+100℃, which can be extended to +135℃ according to the actual situation, and the temperature control accuracy is plus or minus 0.5℃. Theequipment can control the flow and pressure independently while c…

KRY -40℃~+100℃ (1to3)

Dimension(A) cm Temperature range is -40℃~+100℃, which can be extended to +135℃ according to the actual situation, and the temperature control accuracy is plus or minus 0.5℃. Theequipment can control the flow and…

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier