Chiller VS. Heat Exchanger: What is the Difference

Many people use the terms chiller and heat exchanger as if they were the same thing. But when you stand in a factory and look at the piping, pumps, and control systems, the difference is clear. This article explains the difference so you can see how each works in practice.

What is a Chiller

A chiller is a complete refrigeration machine. It removes heat from a process fluid, usually water or a glycol solution, and rejects that heat into air or a secondary water loop.

Think of a chiller as an active device. It does not just transfer heat from one fluid to another. It consumes electrical energy to run compressors and fans(air-cooled chillers). That energy lets it cool well below ambient temperature. The chiller creates a cold source that the rest of the process can rely on.

What is a Heat Exchanger

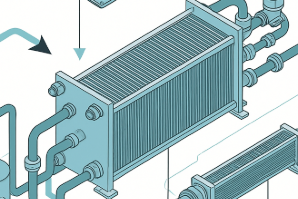

A heat exchanger is different. It does not create a cold source. It only transfers heat between two fluids that are already at different temperatures. The most common types are plate heat exchangers and shell and tube exchangers. Hot fluid passes on one side and colder fluid passes on the other side. Heat flows naturally from the warmer side to the cooler side.

A heat exchanger relies on temperature difference and flow rate. That makes it passive. If you supply chilled water from a central plant, a heat exchanger can isolate that water from your local loop and still deliver cooling. But it cannot cool below the source temperature.

What is the Difference Between Chillers and Heat Exchangers

Function

The function of a chiller is to provide cooling independent of ambient temperature. It can bring water down to 7 degrees Celsius even when the outdoor air is 35 degrees Celsius. The chiller acts like a stand alone cold generator.

The function of a heat exchanger is to allow two fluids to exchange heat without mixing. In breweries people use them to cool wort with city water. In power plants people use them to condense steam with river water. The device itself does not decide the final temperature. It depends on the supply conditions.

Structure

A chiller is a system inside a single frame. You see compressors, pumps, condensers, evaporators, control boards, and safety devices. Many have insulated tanks to buffer capacity. They are heavy machines with many sensors.

A heat exchanger is simpler. It is often a compact block of stainless steel plates brazed together or a bundle of tubes inside a shell. There is no electrical panel or moving part. All you see are inlet and outlet connections. Size depends on flow and duty, not on active components.

Because of this structural difference, installation also changes. A chiller needs power supply, refrigerant checks, and often ventilation or cooling water. A heat exchanger needs only correct piping and pressure rating.

Working Principle

The working principle of a chiller is the vapor compression refrigeration cycle. The compressor moves refrigerant through the loop. In the evaporator the refrigerant boils and absorbs heat from the process fluid. In the condenser the refrigerant releases heat to the environment. Expansion valve controls the pressure drop. Sensors and a controller maintain set temperature by modulating compressor speed or by cycling.

The working principle of a heat exchanger is simple thermodynamics. Heat transfers from the fluid with higher temperature to the fluid with lower temperature through a solid surface. The rate depends on temperature difference, surface area, and fluid velocity. No moving part is needed other than the pumps that move the fluids.

Temperature Control Ability

A chiller can hold outlet temperature very close to setpoint. Modern process chillers reach stability of ± 0.1 ℃. High precision units can do even tighter control. Since the compressor responds to load changes, the chiller can follow demand even if the process varies during the day.

A heat exchanger cannot create its own control band. It follows whatever inlet conditions you provide. If the supply chilled water is stable, the outlet of the process loop is stable. If supply varies, the outlet varies. The heat exchanger itself adds almost no delay but it cannot improve precision.

Energy Consumption

A chiller consumes power because it runs a compressor, fans, and pumps. Efficiency is measured as coefficient of performance. Modern variable speed chillers can reach COP values of 4 to 6 depending on conditions.

A heat exchanger consumes almost no power by itself. Only the circulation pumps draw energy. That makes it very efficient as long as a suitable cooling or heating source is already available. For facilities with a central chilled water plant, heat exchangers are an economical way to distribute cooling without installing more compressors.

Applications

Chillers appear in injection molding, medical imaging, chemical reactors, and battery testing. They are chosen when a process needs temperatures below ambient or when precise stability is critical. Chillers used where the risk of overheating could damage product quality or safety.

Heat exchangers appear in HVAC, power plants, breweries, and district heating. They are chosen when two fluids must exchange heat without mixing. They also appear as economizers, recovering heat from exhaust streams and reusing it elsewhere.

In some plants both are used together. A chiller produces cold water at a setpoint. A heat exchanger transfers that cold to another loop that uses a different fluid or different pressure.

Conclusion

If you need controlled cooling below ambient or very stable setpoints, a chiller is the right tool. If you only need to move heat from one stream to another with little energy use, a heat exchanger is enough. Many facilities use both in sequence.

Our experts recommend starting with process requirements. Write down target temperature, tolerance, and available utilities. Then match the equipment type to those needs.

- Chiller Components and Refrigeration Fundamentals Guides

- Chiller Types and Selection Guides

- How Does a Peltier Cooler Work

- Peltier Chiller vs. Compressor Chiller

- What Is a Peltier Chiller

- OEM vs Aftermarket Chiller Spare Parts

- Chiller Surge

- Chiller Cooling Capacity Units

- December 2025

- November 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- September 2023

- July 2023

- June 2023

- May 2023

- January 2023

air cooled chiller chiller Chiller Installation Chiller Maintenance chiller refrigerant chillers Cold Assembly Freezer cooling chiller cooling heating system cooling system dynamic temperature control system energy efficient chiller explosion-proof chiller freezer heating circulator industrial chiller industrial chillers industrial cooling industrial freezer industrial refrigerator jacket reactor laboratory chiller low temperature chiller news oil chiller process chiller process cooling reactor chiller reactor cooling reactor cooling heating reactor heating cooling refrigerated circulator screw chiller semiconductor chiller semiconductor test chiller sundi tcu temperature control test chamber thermostat ultra low temperature chiller vehicle test chiller water chiller water cooled chiller

Related Chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier