Search the whole station

| Reaction kettle | Fermentation tank | Microreactor | Tubular reactor |

| Vacuum chamber | Freeze-drying machine | Multiphase reactor | Tower reactor |

| Industrial oil treatment | Gas chromatograph | Rotary evaporator | Pilot plant |

| Injection water system | Pharmaceutical water system | Neutralization reaction | Decomposition reaction |

| Oxidation reaction | Polymerization reaction | Crystallization reaction | Fermentation reaction |

| Oil decomposition | Concentration reaction | Extraction System | Laser equipment |

| CNC cooling | Laboratory Testing | Fab equipment | AOI system CMOS/CCD |

| Tool machine | Cooling tower | Battery test cooling | Laboratogy research |

| ATE | Chemical cooling | MRI | CO2 equipment |

| LTZ series | -40℃~90℃ | 5℃~30℃ | -25℃~30℃ | -45℃~20℃ | -60℃~-30℃ | -80℃~-50℃ | -115℃~-80℃ |

| Cooling Capacity | 0.7KW~11.5KW | 23KW~300KW | 7KW~117.5KW | 2.85KW~61.56KW | 4.9KW~93.2KW | 3.7KW~78.5KW | 0.6KW~2.8KW |

| Heating Power | 2.5kW~10KW | ||||||

| Temp control accuracy | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ |

| LT series | -25℃~30℃ | -45℃~30℃ | -60℃~-30℃ | -80℃~-40℃ | |

| Cooling capacity -15℃ |

1.5kw~5kw@-15℃ | 0.7kw~2.5kw@-35℃ | 1.3kw~4.8kw@-40℃ | 0.7kw~2.5kw@-60℃ | |

| Circulation Pump Flow MAX |

30L/min 1.6bar | ||||

| Refrigerant | R-404A / R507C | R-404A / R507C | R-404A/R23 | R-404A/R23 | |

| Temp control accuracy | ±0.5℃ | ||||

| Model | LT Fixed Frequency Series | LTZ Variable Frequency Series | LTZ M Variable Frequency Series | LTG Screw Chiller Series | LTH Deionized-water Series |

| Temperature range | -80℃~30℃ | -115℃~90℃ | 5 ℃~30℃ | -110℃~30℃ | 2℃~+20℃ |

| Type | Air-cooling &Water-cooling | Air-cooling &Water-cooling | Air-cooling &Water-cooling | Water-cooling | Air-cooling &Water-cooling |

| Temp control accuracy | ±0.5℃ | ±0.3℃ | ±0.5℃ | ||

| Cooling capacity | 0.7kW~14kW | 0.7kW~155kW | 3kW~87kW | 9kW~936kW | 5kW~25kW |

| Refrigerant | R-134A/R407C/R-404A/R23/R448A | R-134A /R407C/R507C/R448A | R407C/R448A | R404A/R448A | R134A/R448A |

| Model | KRY -20℃~+100℃ | KRY -40℃~+100℃ | KRY -20℃~+100℃ 6S | KRY -40℃~+100℃ 6S | KRY -40℃~+100℃ 2T | KRY 0℃~+100℃ | KRY 0℃~+100℃ 6S | KRY -40℃~+100℃ 2T |

| Temp control accuracy | ±0.3℃ | |||||||

| Flow rate accuracy | ±0.2 L/min | |||||||

| Heating capacity | 5.5KW~38KW | 5.5KW~60KW | 15KW~38KW | 15KW~38KW | 7.5KW*2~38KW*2 | 2.5KW~38KW | 15KW~38KW | 2.5KW*2~38KW*2 |

| Cooling capacity | 2.8KW~38KW | 1.2KW~60KW | 10KW~60KW | 5KW~60KW | 1.8KW*2~60KW*2 | 1.8KW~60KW | 18KW~60KW | 1.8KW*2~60KW*2 |

| Power 380V50HZ | 11KW~45KW | 10KW~84KW | 36KW~75KW | 38KW~82KW | 28KW~158KW | 4.5KW~61KW | 38KW~82KW | 9KW~120KW |

| FLTZ series | 5℃~90℃ | -25℃~90℃ | -45℃~90℃ | -100℃~+90℃ |

| Temperature control accuracy | ±0.05℃ | ±0.05℃ | ±0.05℃ | ±0.05℃ |

| Cooling capacity | 6KW~40KW @10℃ | 2KW~15KW @-15℃ | 1KW~8KW @-35℃ | 1.5KW~3KW @-90℃ |

| Cooling water flow @20℃ | 1.5m³/h~9m³/h | 1.2m³/H~10.2m³/H | 1.5m³/H~8m³/H | 50L/min~100L/min |

If you haven’t found a suitable model yet, please try contacting us for assistance.

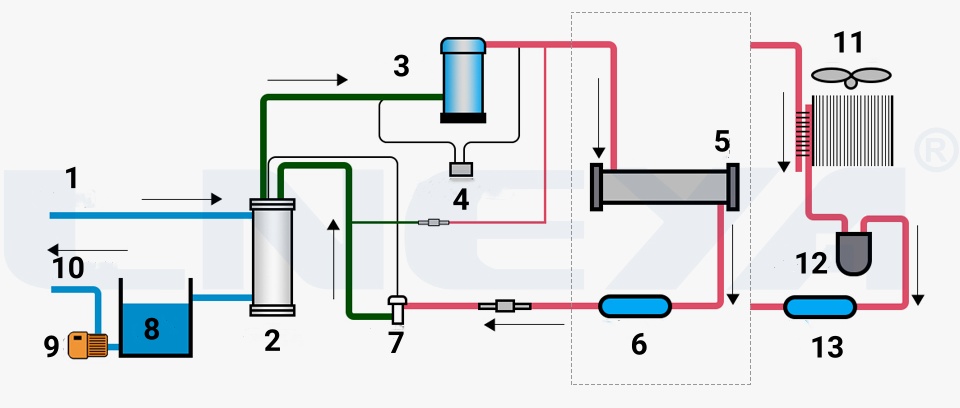

1.Chilled Water Return

5.Water Cooled Condenser

9.Pump

2.Evaporator

6.Filter

10.Freezing Water Outlet

3.Compressor

7.Expansion Valve

11.Air Cooled Condenser

4.Pressure Controll

8.Water Tank

12.Reservoir 13.Filter

Recommended products

Temperature Control :-120℃~350℃

Temperature control for high pressure reactor;Double-layer glass reactor;Double-layer reactor;Microchannel Reactor;Distillation system;Material aging test;Vacuum chamber etc.

Temperature Control: -40℃~100℃

Temperature simulation for vehicle quality test: battery life test, fuel injector/motor test bench, airbag test, component test bench, etc. It can simulate the external environmental conditions in the climate chamber or replace the internal system, which can create the necessary actual temperature conditions for the test bench.

Temperature Control: -85℃~250℃

Suitable for semiconductor process wet washing, photolithography, etching, chemical meteorological deposition, physical meteorological deposition, and the electronics industry (photolithography process)

WeChat/Phone

86 18914253067

+86 18914253067

Email Address

market@lneya.com