What is a chiller? Everything You Should Know

If your application requires an industrial chiller, you need to know some of the basics, which allows you to utilize it in a better way. This article describes the concepts, principles, types, components, and applications of chillers. Keep reading!

What is a Chiller?

A process chiller is a cooling device.It can help you moves heat away from the area you need to cool. It is often used in a variety of processes that require precise temperature control.

Why Need Chillers?

If your process is very sensitive to temperature, such as chemical reactions, semiconductor processes, etc., then you may need a chiller to help you accurately control the temperature.

Many devices will generate waste heat after continuous operation. In order to prevent the equipment from being damaged due to overheating, you need a chiller system to help cool it down.

How Does a Chiller Work?

Working Principles

- Phase Change: Phase change is the change of the state of a substance. Common phase changes include changes between solid, liquid, and gas.

- Latent Heat: When a object undergoes a phase change, it absorbs or releases heat, but the temperature will not change.

- Sensible Heat: When a object absorbs or releases heat, its temperature changes, but no phase change occurs.

- Heat Transfer: Heat is always transferred from a high-temperature to a low-temperature object.

Refrigeration Cycle

The chiller uses refrigerant to absorb the heat of the secondary coolant, which then exchanges heat with other processes. This process needs the cooperation of the compressor, condenser, expansion valve, and evaporator to complete.

The compressor compresses the gaseous refrigerant. It can increase the pressure and temperature of the refrigerant. At the condenser, the hot refrigerant exchanges heat with the outside world (water or air), and it becomes a liquid.

The expansion valve passage is very narrow. When passing through the expansion valve, refrigerant will go from a small space into a wide space. This will reduce the pressure and temperature of the refrigerant.

The low-temperature liquid refrigerant will absorb heat and evaporate at the evaporator. Finally, the gaseous refrigerant will return to the compressor and circulate. This is the refrigeration cycle.

LNEYA chillers working prinple

Chillers Components

The key components of an industrial chiller include a compressor, condenser, expansion valve and evaporator. In actual use, we will add other components.

Compressor

Compressor: The gaseous refrigerant compressed by the compressor will have a higher temperature and pressure. Common compressors include centrifugal, scroll and screw types.

Condenser

The condenser can cool the compressed refrigerant gas to liquid state. The commonly used condensation methods of air-cooled and water-cooled chillers are different. Air-cooled chillers use fans to blow air to cool down, while water-cooled chillers use cooling water from a cooling tower.

Expansion Valve

The passage of the expansion valve is very narrow, and the pressure and temperature of the liquid refrigerant flowing through the expansion valve will be changed by it. Common expansion valves include electronic expansion valves (EEV)and thermal expansion valves (TXV).

Evaporator

The heat exchange process takes place in the evaporator, where the liquid refrigerant absorbs the heat transferred by the refrigerant and evaporates into gas.

Types of Chillers

By Condenser Type

Chillers can be classified into water-cooled and air-cooled types based on the condenser used.

Water-Cooled Chiller

Water-cooled chillers use water to absorb the heat of high-temperature refrigerant, so they are generally equipped with water towers, water pumps and pipes. Their overall footprint is often relatively large, but their cooling efficiency is very high.

Air-Cooled Chiller

Fans can cool the temperature of the refrigerant down. It relies on a suitable temperature environment. If the ambient temperature is high, its efficiency will be reduced.

By Compressor Type

According to the type of compressor used, chillers can be divided into screw chillers, scroll chillers, and centrifugal chillers.

Screw Chiller

This chiller uses a screw compressor. It uses a screw rotor to compress the refrigerant. There are two types: water-cooled and air-cooled. They have a large size ,and usually use in large industrial sites.

Scroll Chiller

The scroll chiller uses a scroll compressor, which has two scrolls, a dynamic scroll and a static scroll. It is very small and is often used in small and medium-sized places.

Centrifugal Chiller

Centrifugal generate centrifugal force by rotating at high speed. They have high speed and power .They are used in some places where require large-scale refrigeration.

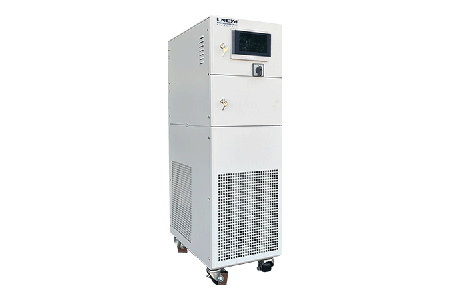

LNEYA have many type chillers such as recirculating chiller water chiller etc.

Chiller Applications

Chillers are widely used across various industrial processes. Here are some common application scenarios:

Laser Cutting

After continuous operation, the laser and the work head of the laser cutting machine will generate a lot of heat. If the equipment cannot be cooled in time, the equipment will be damaged due to thermal stress, resulting in expensive repair or replacement costs.

Injection Molding

In order to cool the mold quickly and improve the demoulding efficiency of the product and the consistency of the finished product batches, chillers are often used in the injection molding process to control the temperature of the mold.

Semiconductor Testing

In order to test the performance of semiconductor components under different extreme temperatures, manufacturers usually use semiconductor chillers to provide a constant temperature environment.

Chemical Reactions

In order to create the right ambient temperature for different chemical reactions, the researchers used a combination of a chiller and a jacketed reactor.

Chiller can be use in chemical reaction or testing process

LNEYA Provides All Industrial Chiller Systems For You!

LNEYA has 15+ years of experience in designing and producing chillers. We provide you with higher quality products to help you perfectly cope with various temperature control challenges in the industry.

Want to know more about chillers? Contact us!

Recommended Chillers

LT 10℃~30℃

chillers machine

cooling capacity 3kW~14kW

circulation pump flow 30L/min 1.6bar~50L/min 2bar

LT -25℃~30℃

cooling circulators

cooling capacity 1kW~5kW

circulation pump flow 30L/min 1.6bar

temperature accuracy ±0.5℃

LT -45℃~30℃

precision chillers

cooling capacity 0.7kW~4.8kW

circulation pump flow 30L/min 1.6bar

temperature accuracy ±0.5℃

LT -60℃~-30℃

refrigerated circulators

cooling capacity 0.7kW~4.8kW

circulation pump flow 30L/min 1.6bar

temperature accuracy ±0.5℃

LT -80℃~-40℃

closed loop chillers

cooling capacity 0.4kW~2.5kW

circulation pump flow 30L/min 1.6bar

temperature accuracy ±0.5℃

LT-800 -18~30℃

mini chiller

cooling capacity 0.35kW~0.9kW

circulation pump flow 10L/min 0.6bar

Chiller Videos

The LNEYA chiller has a temperature control range of 5°C to 35°C, adjustable heat transfer liquid temperature, stable performance, and can work continuously for 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier