Peltier Chiller vs. Compressor Chiller: How to Choose

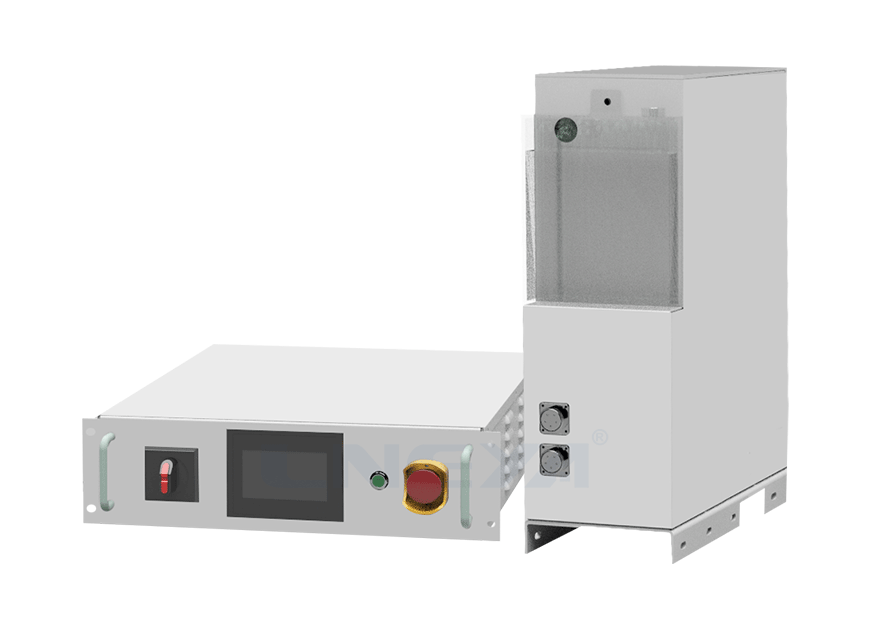

Currently, the most well-known and widely used industrial cooling system is the industrial chiller. Whether water-cooled or air-cooled, most are compressor-based. However, some semiconductor fabs and pharmaceutical industries have begun using Peltier cooling systems.

Why are more and more people choosing Peltier cooling? This article explains the main differences between Peltier chillers and compressor chillers. If you’re unsure which cooling system to choose for your application, this article will be helpful.

1.Basic Principles: Peltier Cooling and Compressor Cooling

How a Peltier or Thermoelectric Cooling System Works

A Peltier or thermoelectric cooling system works by using electrical current to drive heat transfer through a thermoelectric module.

The module contains many tiny semiconductor junctions arranged between ceramic plates. When DC current flows through these junctions, heat is absorbed from the cold side and released on the hot side. The cold side is placed in direct contact with the device, fluid, or sample that requires cooling, so it draws heat away and lowers the temperature precisely.

Meanwhile, the hot side must be actively cooled, usually with a heat sink, cooling fan, or circulating liquid, because it carries both the absorbed heat and the electrical energy added by the module. Without proper heat dissipation on the hot side, the cold side will quickly lose effectiveness.

Temperature control is achieved by adjusting the electrical current. Increasing the current strengthens the cooling effect, reducing it allows the cold side to warm, and reversing the current turns the module into a heater.

Modern Peltier chillers integrate temperature sensors and a PID controller to constantly monitor the cold side and adjust the current, keeping the target temperature stable.

How a Compressor Chiller Works

There’s a blog post that specifically explains how a compressor chiller works, so this article will only provide a brief overview. You can click the link to view that article if needed.

A compressor chiller works by circulating a refrigerant through a closed loop to absorb heat from the process and release it into the environment.

The cycle begins when the compressor pressurizes the refrigerant gas, raising its temperature. The hot, high-pressure gas then flows through a condenser, which removes heat and condenses the gas into a liquid. This liquid passes through an expansion device, which lowers its pressure and temperature, creating cold refrigerant that enters the evaporator.

Inside the evaporator, the refrigerant absorbs heat from the fluid or equipment being cooled, lowering its temperature. The warmed refrigerant then returns to the compressor to repeat the cycle.

The system is controlled by temperature sensors and a controller, which regulate the compressor, pump, and sometimes expansion valves to maintain the target temperature precisely. Air-cooled chillers remove heat through fans and fins, while water-cooled chillers use a secondary water loop to carry heat away.

2.Which One Has Higher Cooling Efficiency?

Peltier chillers have lower efficiency. Compressor chillers deliver higher energy efficiency especially at larger loads.

In real use, a Peltier cooler consumes more electrical power for the same amount of cooling capacity. Its coefficient of performance drops quickly as the temperature difference increases.

Compressor chillers operate more efficiently because refrigerant phase change moves heat more effectively. For any industrial chiller application above a small load, a compressor chiller will run much more efficiently.

3.Temperature Range

Peltier systems offer moderate temperature ranges. Compressor chillers support a wider working range for both low and high temperatures.

Most Peltier cooling setups achieve around 0 to minus 20°C and can reach lower temperatures only with multistage modules. Compressor chillers easily achieve minus 30 to minus 90°C depending on design. They also cover high temperature control tasks with stable performance, making them more flexible for industrial applications.

4.Temperature Stability

Peltier chillers provide excellent precision. Compressor chillers provide good stability but not at the same micro level as thermoelectric cooling.

A Peltier module reacts instantly to small changes in temperature. This makes it valuable for optical instruments, chips, and sensors that require ±0.05°C stability.

Compressor chillers provide tight control but may show slight fluctuations due to the cycling of the compressor.

Most process cooling applications still perform very well with compressor based stability.

5.Response Speed

Peltier chillers respond very quickly. Compressor chillers respond slower due to the refrigerant cycle.

Because thermoelectric systems have no moving parts, they change temperature almost immediately when current changes. This benefits semiconductor testing or biotech analysis where rapid shifts are needed.

Compressor chillers ramp up gradually and stabilize over time, which fits continuous industrial cooling rather than high speed temperature switching.

6.Size and Weight

Peltier chillers are compact and lightweight. Compressor chillers are larger and heavier due to mechanical components.

A Peltier cooling system may fit on a benchtop or inside a small housing. A compressor chiller includes a compressor, condenser, pump, and piping, making it bulkier.

LNEYA also offers portable compressor chillers, which take up only 0.1 ㎡.

7.Noise and Vibration

Peltier chillers operate very quietly. Compressor chillers create more noise and vibration.

Since a Peltier module has no mechanical movement, noise comes only from fans. This is ideal for labs, medical devices, or environments where vibration affects measurements.

Compressor chillers generate noticeable vibration because of the compressor and refrigerant flow. Sensitive instruments usually avoid this type unless isolated properly.

8.Cost

Peltier chillers cost less at small sizes but more at larger capacity. Compressor chillers cost more upfront but offer better cost performance for industrial loads.

A small Peltier cooler is simple to manufacture and has a lower starting price. However, scaling thermoelectric modules becomes expensive and inefficient.

Compressor chillers may cost more initially but deliver far more cooling per dollar at any industrial scale.

These articles may help you learn the price of compressor chillers:

How Cooling Capacity Affects Chiller Price

What Affects Chiller Cost?

Hidden costs of chillers quotes

How Much Does a Chiller Cost

How Much Does an Air-Cooled Chiller Cost

9.Maintenance

Peltier chillers require very little maintenance. Compressor chillers require routine service.

A Peltier module has no wear points. Proper heat dissipation is usually the main concern. Compressor chillers have moving parts, refrigerant, valves, and pumps, all of which need inspection, cleaning, and replacement over time.

10.Applications

Peltier chillers fit precision, small load, and vibration sensitive tasks. Compressor chillers fit industrial, high capacity, and continuous cooling needs.

Thermoelectric chillers are often used in semiconductor metrology, optical systems, biotech analyzers, camera sensors, and laser cooling.

Compressor chillers are common in chemical reactors, wafer manufacturing, pharmaceutical production, pilot plants, and environmental test chambers.

Get a Detailed Quote for Free!

Choosing the Right Cooling System

The best choice depends on cooling load, accuracy requirements, temperature targets, and working environment. You should consider how much heat they need to remove, how stable the temperature must stay, and whether noise or vibration matters to the process.

When to Choose a Peltier or Thermoelectric Cooling System?

A thermoelectric chiller is ideal when precision, low vibration, compact size, or fast response is more important than high cooling capacity.

It fits sensors, laser systems, microfluidic devices, or semiconductor tools with low heat loads.

Users choose Peltier cooling when they need quiet operation and simple maintenance.

When to Choose a Compressor Chiller?

A compressor chiller should be selected when the application requires strong cooling power, wide temperature ranges, or continuous 24 hour operation.

It suits industrial chiller systems, reactors, process equipment, and large laboratory instruments.

Users choose compressor chillers when stability, efficiency, and long term reliability are top priorities for production environments.

Get a Free Customized Cooling Solution and Quote

If you still have questions about the differences between Peltier cooling and compressor chillers, or you are not sure which system fits your application, our team is here to help.

LNEYA has more than fifteen years of experience in designing and building temperature control systems, and we can help you customize the solution that works best for your needs.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier