What Is a Peltier Chiller

When think of cooling, most people imagine refrigerators or industrial HVAC systems. These are popular in the cooling industrial, driven by compressors and refrigerants.

But for applications that demand cooling a delicate laser diode, maintaining the exact temperature of a biological sample, or fitting a cooling unit into a small space, the Peltier chiller is the best choice.

This guide explains what a Peltier chiller is, how it operates and where it performs best.

What Is a Peltier Chiller?

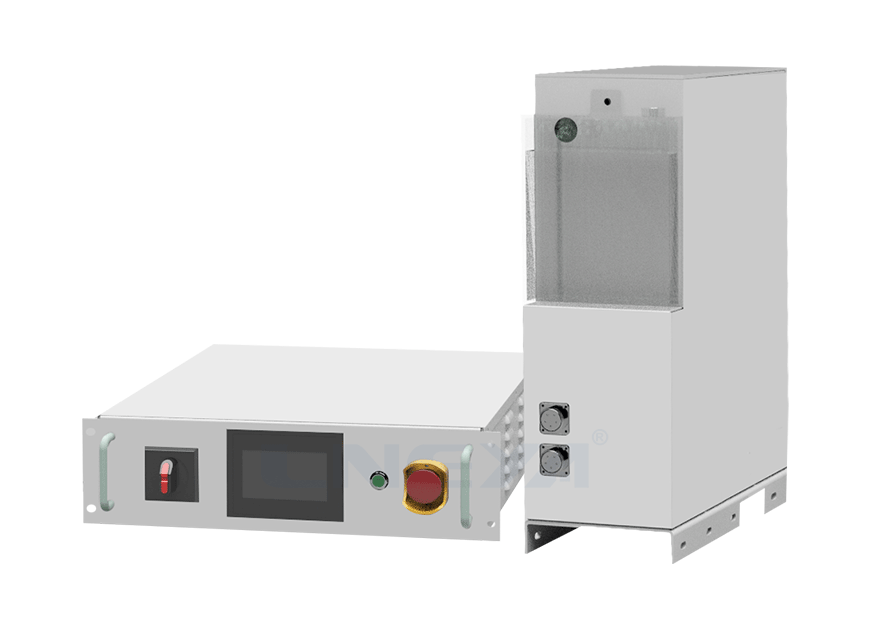

A Peltier chiller is a temperature control system that uses thermoelectric modules to generate heat or cold. Unlike traditional industrial chillers, it eliminates the need for compressors and refrigerants. Temperature is controlled through heat transfer as electric current flows through the Peltier module.

A Peltier cooler handles small to medium heat loads with impressive stability and minimal vibration. It is commonly used in laboratory instruments, semiconductor testing and compact analytical devices.

A typical Peltier chiller includes a thermoelectric module, a cold plate, an internal fluid loop and a heat sink or liquid side exchanger. It operates entirely through electrical current. This makes the system simple to control and very responsive.

How Does a Peltier Chiller Work?

A Peltier chiller works by using the Peltier effect to move heat from one side of a thermoelectric module to the other. When electrical current passes through the module, one surface becomes cold and the opposite surface becomes hot. This controlled heat transfer creates a stable cooling loop for circulating fluid.

Inside each Peltier module are many pairs of N type and P type semiconductor elements. They are connected electrically in series and thermally in parallel. When current flows across the junctions, electrons and holes carry heat in one direction.

Heat is absorbed at one junction, creating the cold side, and released at the opposite junction, creating the hot side. Reversing the current direction reverses the heating and cooling sides.

A Peltier chiller integrates these modules into a complete temperature control system. The cold side is bonded to a cold plate or heat exchanger that cools the circulating fluid. The fluid then transfers the cold energy to the user’s equipment, such as a sensor, optical component or microreactor.

The hot side is attached to a heat sink, fan system or secondary liquid loop that removes waste heat. This hot side rejection is essential because any buildup directly reduces cooling performance.

Sensors monitor the fluid temperature and the controller adjusts current to the modules to achieve the desired setpoint. Since the cooling output responds immediately to current changes, the chiller can maintain tight temperature stability without overshooting.

The system operates entirely through solid state heat transfer, which eliminates the need for compressors, refrigerants or mechanical expansion cycles.

What Are the Advantages of a Peltier Chiller?

A Peltier chiller offers precise temperature control, quiet operation and reliable performance in compact systems.

1.Highly Precise Temperature Control

A Peltier chiller adjusts cooling output by simply changing the electrical current. This allows extremely fine temperature control within a narrow band.

For example, a CCD or CMOS imaging sensor often requires stability within tenths of a degree to prevent image noise. A Peltier module reacts instantly to temperature drift, allowing the system to maintain consistent image quality during long measurement periods.

2.No Vibration for Sensitive Instruments

Because Peltier modules have no moving parts, they generate no vibration.

This matters in optical benches, interferometers or laser alignment systems where even small vibrations can shift a beam path or disturb measurement accuracy. A compressor chiller cannot offer the same quiet and stable operating environment.

3.Compact Size for Space Limited Designs

Peltier chillers are much smaller than compressor based systems, making them ideal for instruments where internal space is tight.

A typical benchtop analyzer or handheld diagnostic device cannot fit a full refrigeration circuit. A Peltier cooler, however, can be integrated directly next to the component that needs cooling, reducing thermal losses and improving efficiency.

4.Clean Operation with No Refrigerants

Peltier chillers use thermoelectric modules, so there is no refrigerant to leak or maintain.

This is important in medical devices, biotech tools and chemical analysis instruments that must avoid contamination. Since the cooling process is entirely electronic, maintenance is limited mostly to the fluid loop and heat sink.

5.Fast Response for Dynamic Temperature Profiles

Because cooling power depends on electrical current, Peltier systems can heat or cool rapidly.

For instance, a microreactor used in research often requires quick temperature shifts to simulate reaction conditions. A Peltier chiller can switch from cooling to heating by reversing current, achieving fast transitions without overshooting the target temperature.

6.Reliable Operation with Minimal Maintenance

The solid state nature of Peltier modules means they do not wear out like compressors, valves or mechanical pumps.

In semiconductor test chambers or environmental control systems that run continuously, this long term reliability reduces downtime. Many users find that even though the initial Peltier cooler price may be higher, the low maintenance cost over time provides a better total cost of ownership.

7.Environmentally Friendly Thermal Control

With no refrigerants, oil or compressor noise, Peltier chillers provide an environmentally friendly cooling solution.

This is beneficial for laboratories that follow strict environmental compliance or companies trying to reduce long term regulatory risks associated with refrigerant management.

Get a more efficient and reliable cooling solution.

What Are the Limitations of a Peltier Chiller?

A Peltier chiller performs best in low to medium heat load applications. It is not designed for large cooling demands or extreme temperature differences.

1.Lower Cooling Capacity Compared to Compressor Systems

Peltier modules cannot remove heat as efficiently as vapor compression chillers.

For example, trying to cool a reactor jacket that generates hundreds of watts of heat will quickly exceed the capability of most Peltier chillers. The system will struggle to hold the setpoint because thermoelectric modules are designed for smaller thermal loads, typically found in benchtop instruments or small components.

2.Reduced Efficiency at Large Temperature Differences

A Peltier module becomes less efficient when asked to maintain a temperature far below ambient.

If a laboratory instrument requires fluid at zero degrees Celsius while the room is warm, the module must work harder, generating extra heat on the hot side. As the temperature gap widens, power consumption rises and cooling capacity drops. This makes thermoelectric systems unsuitable for heavy duty low temperature applications.

3.High Heat Rejection Requirements

The hot side of a Peltier module produces significant waste heat that must be removed quickly.

If the heat sink or liquid cooling loop is undersized, performance will decline or the module may overheat. This is common when users try to install a Peltier cooler into a compact enclosure without enough airflow. Proper thermal design on the hot side is essential for long term reliability.

4.Initial Cost Can Be Higher for High Quality Modules

A well engineered Peltier chiller uses premium thermoelectric modules, advanced controllers and stable power electronics.

These components can increase the initial Peltier cooler price compared with entry level compressor chillers.

5.Not Ideal for Large Systems or Multi Kilowatt Cooling

Thermoelectric cooling does not scale well to large applications. Cooling an industrial reactor, a high power laser cabinet or a large environmental chamber generally requires kilowatts of cooling capacity. A Peltier system cannot meet this requirement. In these cases, a compressor chiller or a hybrid cooling solution is the better choice.

What Applications Use Peltier Chillers?

Peltier chillers are widely used in industries where compact size, low vibration and precise temperature control are essential. Their strength lies in supporting small components, analytical systems and sensitive devices that cannot tolerate thermal drift or mechanical disturbance.

1.Laboratory and Analytical Instruments

Many benchtop instruments depend on stable temperature to ensure accurate measurements. Peltier chillers are commonly used in spectrometers, chromatography detectors, microreactors and DNA amplification systems.

2.Semiconductor Testing and Sensor Cooling

Peltier chillers help cool CCD or CMOS imaging sensors, wafer inspection stages and metrology instruments. A typical example is a semiconductor test fixture where a stable cooling source is needed to prevent temperature drift during long duration reliability tests.

3.Medical and Biotech Equipment

PCR systems, diagnostic analyzers and microfluidic platforms often integrate Peltier modules. A Peltier chiller can cool reagents or samples quietly and precisely.

4.Precision Optics and Laser Systems

Peltier chillers support laser diodes, optical benches and interferometry systems by providing stable, vibration free cooling.

5.Research and Development Prototyping

Peltier chillers allow researchers to quickly test thermal behavior of new materials, sensors or electronic components without building a full refrigeration system. Their solid state design makes them easy to mount and control during prototype development.

6.Portable or Space Constrained Devices

Some instruments must operate inside tight enclosures or portable housings where a compressor system cannot fit.

A Peltier chiller is ideal for handheld diagnostic devices, battery powered analyzers or compact field inspection tools. It offers enough cooling capacity for small heat loads while keeping the device lightweight and low noise.

Peltier Chiller vs. Compressor Chiller: Which Should You Choose?

The best decision depends on the actual operating conditions, ambient environment and required control precision. A Peltier chiller is the better choice for precise, low vibration and compact cooling. A compressor chiller is better for high capacity and wide temperature ranges.

If a system requires tight temperature stability, clean operation and minimal maintenance, a Peltier structure often delivers a more reliable experience. It is ideal for analytical instruments, semiconductor components and compact laboratory systems.

If the load is high or the target temperature is far below ambient, a compressor chiller performs better. It handles larger heat loads efficiently and can maintain low temperatures over extended periods.

Explore LNEYA Peltier chillers and compressor chillers

Unsure which chiller is best suited for your application? The LNEYA team is happy to help you determine the optimal cooling solution. We offer free technical support and quotes for Peltier chillers and compressor chillers.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier