What is Chiller COP:Key Factors Affecting Performance

You may often see the abbreviation COP, but do you know what it means? This article will tell you everything about the chiller COP . If you are interested in this, continue browsing!

What is Chiller COP?

COP is the abbreviation of coefficient of performance. It is a numerical value without units. Professionals define it as the ratio of the cooling capacity of the chiller (kWR) to the electrical energy (kWE) required to produce this cooling capacity. Their units are all kilowatts (kW).

What Does COP Stand for?

What the COP of a chiller means?

The higher the COP of a chiller, the more cooling capacity it can provide when consuming 1kW of electricity. A higher COP chiller help you use energy more efficiently and shorten your electricity bill. Moreover, this is in line with the value concept of sustainable development.

How to Calculate COP?

After understanding the meaning of COP, how to compute efficiency? Some chiller manufacturers will tell you directly, and in some cases you need to calculate it yourself. According to the definition, we know:

COP = kilowatts of refrigeration (kWR) / kilowatts of electricity (kWE)

If the cooling power of your chiller is 2000kW. In order to achieve this cooling capacity, this chiller needs to consume 400kW electricity. So, how to calculate its COP?

COP=2000kW/400kW=5

In other words, for every 1kW of electricity consumed, it can generate 5kW of cooling capacity.

Chiller COP Related Factors

Higher COP means higher resource utilization. So, what factors are related to COP?

- Condenser and evaporator efficiency-When the heat exchanger is blocked, the heat exchange efficiency will be affected. In order to produce the same cooling capacity, the compressor needs to work longer, which will reduce the chiller COP.

- Ambient temperature and cooling water temperature-Excessively high temperature on the condenser side will affect the heat dissipation of the refrigerant, resulting in reduced refrigeration efficiency.

- Compressor performance-Different types of compressors have different performances in the face of changing load conditions, which in turn affects the chiller COP.

- Maintenance cycle-Different components in the chiller system have different maintenance cycle requirements. If they are not maintained for a long time, the equipment will have various problems, resulting in a decrease in COP.

- Load state- Generally, the COP reaches its highest point at maximum load. But in fact, many chillers are in a partial load state for most of their life cycle.

How to Improve Chiller COP?

How to improve the chiller COP? Because COP = cooling capacity / power, if you want to improve COP, you can start from two directions: the first is to reduce the power consumption of the chiller, and the second is to improve its efficiency of refrigeration. So, you can do this:

- Use electronic expansion valve-Compared with thermal expansion valve, electronic expansion valve has higher temperature control accuracy. It can adjust the opening according to the real-time cooling temperature to improve COP.

- Use variable frequency equipment-Variable frequency compressor can automatically adjust the speed of the compressor according to the actual cooling load to reduce power consumption. In addition, there are variable frequency pumps and variable frequency fans. They can help you improve the COP at partial load.

- Use high-efficiency heat exchanger-Different heat exchangers have different heat exchange areas per unit volume. You can choose a heat exchanger with higher heat transfer efficiency. For example, plate heat exchangers, etc.

- Perform regular maintenance-You need to maintain the chiller system in strict accordance with regulations. Maintenance includes checking the operating status, troubleshooting abnormalities, replacing consumables, cleaning parts, etc.

COP VS EER

Both coefficient of performance (COP) and energy efficiency ratio (EER) are indicators for measuring the efficiency of refrigeration equipment.

The energy efficiency ratio indicates the cooling capacity of the refrigeration equipment under unit power.

Unlike the COP indicator widely used in industrial refrigeration and heat pump systems, EER is often used to measure the energy efficiency of air conditioning systems. It is calculated as follows:

EER (BTU/hr·W) = cooling capacity (BTU/hr) / input power (W)

kW is an international unit and BTU/hr is an imperial unit. COP and EER can be converted interchangeably.

1 kW = 3412 BTU/hr,

1 kilowatt (kW) = 1000 watts (W)

↓

EER ≈ COP × 3.412

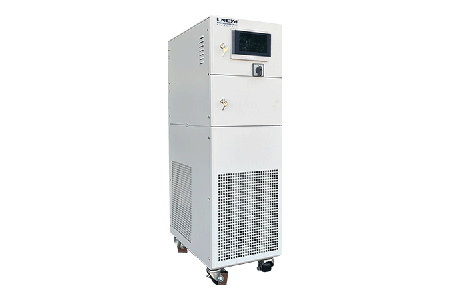

Customize Higher COP Chiller

As a chiller manufacturer, LNEYA can customize higher COP chillers for you according to your budget and application. Contact us now to solve various industry temperature challenges for you!

Contact LNEYA

Submit your request to us and we will contact you within 24 hours

Recommended chillers

LT 10℃~30℃

chillers machine

cooling capacity 3kW~14kW

circulation pump flow 30L/min 1.6bar~50L/min 2bar

LT -25℃~30℃

cooling circulators

cooling capacity 1kW~5kW

circulation pump flow 30L/min 1.6bar

temperature accuracy ±0.5℃

LT -45℃~30℃

precision chillers

cooling capacity 0.7kW~4.8kW

circulation pump flow 30L/min 1.6bar

temperature accuracy ±0.5℃

LT -60℃~-30℃

refrigerated circulators

cooling capacity 0.7kW~4.8kW

circulation pump flow 30L/min 1.6bar

temperature accuracy ±0.5℃

LT -80℃~-40℃

closed loop chillers

cooling capacity 0.4kW~2.5kW

circulation pump flow 30L/min 1.6bar

temperature accuracy ±0.5℃

LT-800 -18~30℃

mini chiller

cooling capacity 0.35kW~0.9kW

circulation pump flow 10L/min 0.6bar

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier