Search the whole station

WHATSAPP WECHAT Ultra high temperature cooling technology can directly cool from a high temperature of 300℃[because only the heat transfer medium in the expansion…

Fully enclosed system, single medium completes refrigeration and heating -120~350℃ ±0.5℃ AC 380V 50HZ 8kW max Ultra high temperature cooling technology can directly cool from a hi…

● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control ● Maximum process stability and reproducibility ● Adop plate heat exchager, Pipeline heating, the fastest he…

Fully enclosed system, single medium completes refrigeration and heating -120~350℃ ±0.5℃ Ultra-high Temperature Cooling Technology Can Directly Cool Down From 300℃ High Temperature. Bec…

Fully enclosed system, single medium completes refrigeration and heating -120~350℃ ±0.5℃ ● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control…

● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control ● Maximum process stability and reproducibility ● Adop plate heat exchager, Pipeline heating, the fastest heat…

Ultra high temperature cooling technology can directly cool from a high temperature of 300℃[because only the heat transfer medium in the expansion chamber contacts with ox…

● Working temperatures from -120°C to +350°C● Previously unachievable performance●Intelligent temperature control● Maximum process stability and reproducibility● Adop plate heat exchager, Pipeline heating, the fastest heating…

● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control ● Maximum process stability and reproducibility ● Adop plate heat exchager, Pipeline heating, the fastest heat…

● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control ● Maximum process stability and reproducibility ● Adop plate heat exchager, Pipeline heating, the fastest h…

loading…

已经是到最后一篇内容了!

ZLF\SR\DCS Series

TCS integrated Reactor temperature control system First, advanced design conceptThis solution is based on the advanced process control system SIMATIC PCS 7 design. It refers to the advanced concept of real-time release testing in…

TCU temperature control system USES the existing heat (such as steam, cooling water and cryogenic liquid – the “primary”) system infrastructure are integrated into the single fluid system was used to control the temperature o…

Special temperature control system for reaction kettle -120~250℃ 士1°C TCU temperature control system USES the existing heat (such as steam, cooling water and cryogenic liquid – the “primary”) system infr…

loading…

已经是到最后一篇内容了!

适用范围 Product Features 产品参数 Product Parameter 行业应用 APPLICATION 航空航天材料|试验装置控温解决方案 在航空航天领域,材料的性能直接关系到飞行器的安全、可靠性和…

Fast cooling and low cooling temperature -5~-150°C Water Cooling LNEYA specializes in the production of single-fluid cryogenic chillers. The refrigeration temperature ranges from -150°C to -5°C, which can mee…

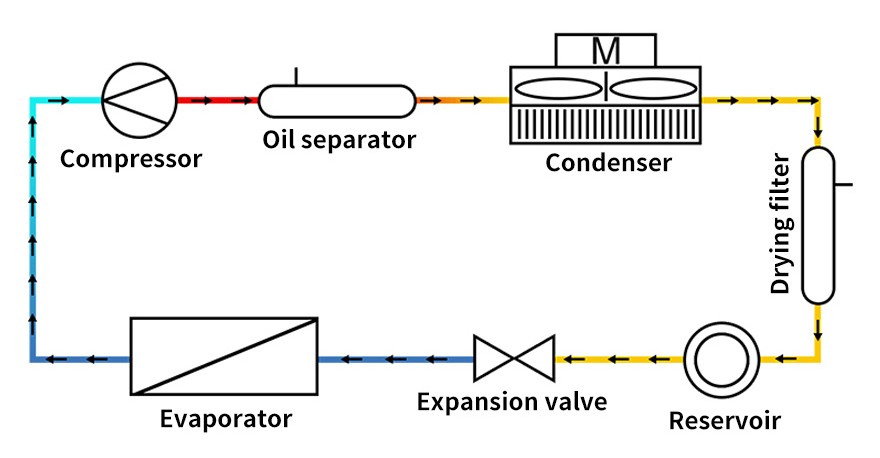

1.Temperature ranges from -5℃ ~ -150℃, can meet different temperature2. Famous brand semi-closed piston compressor, semi-closed bipolar piston compressor, semi-hermetic screw compressor, main brand are BOCK. Bitzer, Cop…

1.Temperature ranges from -5℃ ~ -150℃, can meet different temperature2. Famous brand semi-closed piston compressor, semi-closed bipolar piston compressor, semi-hermetic screw compressor, main brand are BOCK. Bitzer,…

5kW Chiller; 10kW Chiller; 30kW Chiller; 60kW Chiller; 120kW Chiller Widely used in chemical, pharmaceutical, biochemical and other industries in the field of low temperature reaction, refrigeration speed, safety and reliabil…

loading…

已经是到最后一篇内容了!

LC/LJ/LN/LD/CDLJ/SLJ series

Applications:

Widely used in chemical, pharmaceutical, biochemical and other industries in the field of low temperature reaction, refrigeration speed, safety and reliability. The company developed a direct-cooled ultra-low temperature chiller, using international brand compressors Carrier, using automatic cascade refrigeration mode and mixed refrigerants, within 3 minutes can be refrigerated to minus 120°C.

Features:

The product adopts the international brand compressor Carlyle, which is small in size and high in efficiency. The single compressor can realize the temperature control of -152 °C, and the ultra-low temperature refrigeration technology is at the international advanced level.

适用范围 Product Features 产品参数 Product Parameter 行业应用 APPLICATION 航空航天材料|试验装置控温解决方案 在航空航天领域,材料的性能直接关系到飞行器的安全、可靠性和…

Fast cooling and low cooling temperature -5~-150°C Water Cooling LNEYA specializes in the production of single-fluid cryogenic chillers. The refrigeration temperature ranges from -150°C to -5°C, which can mee…

1.Temperature ranges from -5℃ ~ -150℃, can meet different temperature2. Famous brand semi-closed piston compressor, semi-closed bipolar piston compressor, semi-hermetic screw compressor, main brand are BOCK. Bitzer, Cop…

1.Temperature ranges from -5℃ ~ -150℃, can meet different temperature2. Famous brand semi-closed piston compressor, semi-closed bipolar piston compressor, semi-hermetic screw compressor, main brand are BOCK. Bitzer,…

5kW Chiller; 10kW Chiller; 30kW Chiller; 60kW Chiller; 120kW Chiller Widely used in chemical, pharmaceutical, biochemical and other industries in the field of low temperature reaction, refrigeration speed, safety and reliabil…

loading…

已经是到最后一篇内容了!

LOW TEMPERATURE COOLING CIRCULATOR For fast liquid cooling 1. Can use ethylene glycol mixed with water for circulating refrigeration, saving resources 2.Circulating pipeline design, prolong t…

Saving water resources & circulating cooling 1. Can use ethylene glycol mixed with water for circulating refrigeration, saving resources 2.Circulating pipeline design, prolong the use time of circulating …

Rapid refrigeration using imported brand semi-enclosed piston compressor, semi-enclosed piston two-stage compressor, semi-enclosed screw compressor 1. Can use ethylene glycol mixed …

loading…

已经是到最后一篇内容了!

Temperature Control :-120℃~350℃

Temperature control for high pressure reactor;Double-layer glass reactor;Double-layer reactor;Microchannel Reactor;Distillation system;Material aging test;Vacuum chamber etc.

Temperature Control: -40℃~100℃

Temperature simulation for vehicle quality test: battery life test, fuel injector/motor test bench, airbag test, component test bench, etc. It can simulate the external environmental conditions in the climate chamber or replace the internal system, which can create the necessary actual temperature conditions for the test bench.

Temperature Control: -85℃~250℃

Suitable for semiconductor process wet washing, photolithography, etching, chemical meteorological deposition, physical meteorological deposition, and the electronics industry (photolithography process)

Wechat 18914253067

Whatsapp +86 18914253067

Email: sales@cnzlj.com