YQH 0℃~-75℃

Waste gas condensation capture and recovery;Semiconductor exhaust gas purification- Cold-zone Pressure8 Bar

- Cooling Water @25℃1300L/H~3000L/H 1BAR~4BAR

- Power3kW~8kW

Product data download

VOCS gas condensation capture and recovery

Suitable for the recovery of various volatile VOCs gases; Fast cooling, high efficiency, meeting different condensing temperature requirements, low temperature can reach -75 ° C

Where do harmful gases come from?

It mainly comes from the cleaning, glue leveling, glue removal, etching and development processes of chip or circuit board production.

high exhaust volume and Low emission concentration

The core process of integrated circuit manufacturing produces a large amount of acid-base, arsane, phosphine, organic and other process waste gases. A local scrubber is required for waste gas condensation capture and recovery.

Organic waste gas mainly comes from cleaning, CVD, photolithography, wet etching, degumming and diffusion processes. The types of organic waste gas mainly include isopropyl alcohol, acetone, propylene glycol monomethyl ether acetate, ethyl lactate, butyl acetate, heavy aromatics, etc.

parameter

|

Model |

YQH-3520EXd YQH-3520Wexd |

YQH-7520EXd YQH-7520WEXd |

YQH-3530EXd YQH-3530WEXd |

YQH-7530EXd YQH-7530WEXd |

|

Gas flow |

20m3/h |

20m3/h |

30m3/h |

30m3/h |

|

Lowest temperature |

-35℃ |

-75℃ |

-35℃ |

-75℃ |

|

First level temperature |

0℃ |

0℃ |

0℃ |

0℃ |

|

Cold box pressure |

8bar |

8bar |

8bar |

8bar |

|

Heat exchange area |

3m2*2 |

3m2*2 |

5m2*2 |

5m2*2 |

|

Heat exchanger material |

SUS304 |

SUS304 |

SUS304 |

SUS304 |

|

Pressure monitoring |

Anti-ice blocking pressure monitoring and protection for the inlet and outlet of the primary and secondary evaporation traps |

|||

|

Defrost control |

Defrost control can be performed based on pressure monitoring |

|||

|

Air inlet diameter |

DN40 PN16 |

DN40 PN16 |

DN50 PN16 |

DN50 PN16 |

|

Recovery liquid storage tank |

10L Optional installation of recovery transfer pump |

15L Optional installation of recovery transfer pump |

||

|

Drain port diameter |

G1/2 |

G1/2 |

G1/2 |

G1/2 |

|

Control System |

Siemens PLC |

|||

|

Display and record |

7-inch color touch screen |

|||

|

Compressor |

Emerson Copeland Scroll flexible compressor (explosion-proof is epoxy resin encapsulated) |

|||

|

Power supply 380V 50HZ MAX |

3.5KW |

5KW |

4KW |

6KW |

|

Size |

800*1200*1850 |

800*1200*1850 |

1000*1500*1850 |

1000*1500*1850 |

|

Cooling water (water cooling)20℃ |

1800L/H 1BAR~4BAR G3/4 |

3000L/H 1BAR~4BAR G3/4 |

||

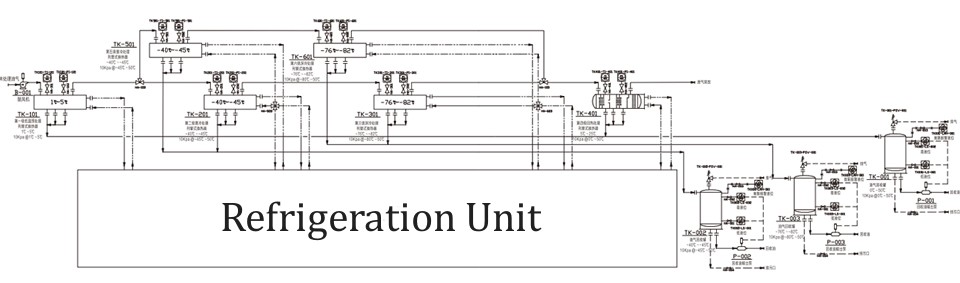

working principle

Introduce the volatile VOCS gas into the equipment cold box (the device is set to a condensation temperature of 3°C-40°C-75°C-115°C). Other temperature zones can be customized to follow the needs for step-by-step condensation and liquefaction. Some continuous production processes have a dual-channel switching process in the low-temperature section (after one side is blocked by ice, it is directly switched to the other channel for heat exchange and condensation in the cold box, and at the same time, the ice blockage is tested for defrost treatment).

Customized 25 BAR

Heat exchange system pressure resistance

-40~-75℃

Meet different temperatures

recommend products

MD Series Chuck

-75℃ to 225°C Model MD-708 MD-712 MDL-708 Temp. Range -75℃~225℃ -75℃~225℃ -75℃~225℃ Temperature control accuracy ±0.1℃ ±0.1℃ ±0.1℃ temperature uniformity ±1℃ ±1℃ ±1℃ Flatness ±50um ±50um ±50um Tablet Size 200mm diameter d…

FLT-100℃~90℃

Single channel air-cooled cooler, mainly designed for etching machines. It is used to provide independent temperature control for the chamber sid…

FLTZ -45℃~90℃

Heating method within 40 ℃ adopts a compressor hot gas heating fully enclosed design, and the machine operates continuously for 24 hours The semiconductor temperature control device Chiller is mainly used for p…

ZLJ Series

Multiple control requirements can be achieved by merging multiple devices into a larger cabinet Used for small heat exchange area and large heat exchange capacity The product directly outputs and…

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier