Thermal Chillers for Semiconductor ATE & Process

Advanced liquid temperature control technology, actively exploring and researching component test systems, mainly used for temperature test simulation in pharmaceutical chemicals, new energy, semiconductors, and aerospace testing, with wide temperature direction and high temperature rise and fall, temperature range: -80°C~+90°C, temperature control accuracy up to: ±0.05℃, suitable for various test requirements.

Applications

Temperature control system for production process and testing links.

Applied in semiconductors, LEDs, LCDs, solar photovoltaics and other fields;

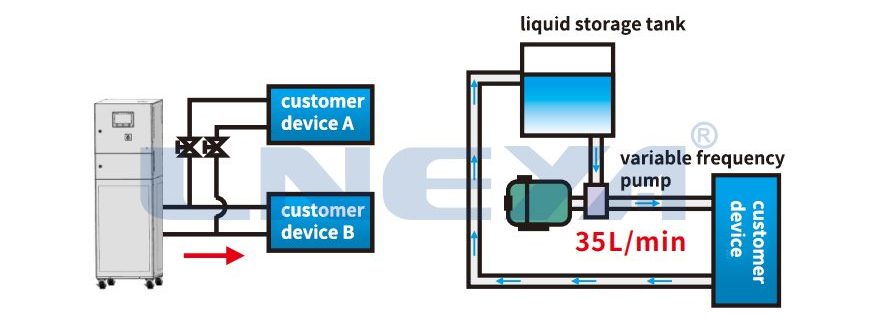

The variable frequency pump can adjust the circulating fluid pressure and flow, Circulation heating can be achieved without a heater;

Multi-channel independent temperature control, no mutual influence.

Such as chillers that control the processing temperature on the Fab equipments.

Cooling of CMOS/CCD sensors in semiconductor metrology systems.

Recirculating Chiller for semiconductor metering AOI system.

Single channel air-cooled cooler, mainly designed for etching machines. It is used to provide independent temperature control for the chamber side walls.

Used for plasma bevel etch and deposition; Thermal Atomic Layer Etching of Metal Tungsten.

FLTZ Frequency Conversion Series

Temperature control range: -45℃~+90℃

The chiller’s exhaust and suction temperature (pressure), condensing temperature, cooling water temperature (pressure), inlet and outlet liquid (gas) temperature (pressure), power consumption, current of each component, voltage, water tank level and other important information are all connected to the control system through sensors for comprehensive management, monitoring and recording.

| Model |

5℃~90℃ |

-25℃~90℃ |

-45℃~90℃ |

-80℃~+90℃ |

-100℃~+90℃ |

| Temperature control accuracy |

±0.05℃ |

±0.05℃ |

±0.05℃ |

±0.05℃ |

±0.05℃ |

| Cooling capacity |

6KW~40KW @10℃ |

2KW~15KW @-15℃ |

1KW~8KW @-35℃ |

0.6KW~3KW @-70℃ |

1.5KW~3KW @-90℃ |

Rated test conditions for all equipment: Dry bulb temperature: 20℃; Wet bulb temperature: 16℃. Inlet water temperature: 20℃; Outlet water temperature: 25℃.

FLTZ Frequency Conversion Multi-channel Series

Temperature control range: -45℃~+100℃

Multi channel independent temperature control, which can have a separate temperature range, cooling and heating capacity, thermal conductivity medium flow rate, etc., adopts two independent systems.

The system can be used for universal expansion tanks, condensers, cooling water systems, etc., which can effectively reduce equipment size and operation steps.

| Model |

FLTZ-203W/2T dual system |

FLTZ-305W/2T dual system |

FLTZ-406W/2T dual system |

| Temperature range |

-20℃~90℃ |

-30℃~90℃ |

-45℃~90℃ |

| Temperature control accuracy |

±0.1℃ |

| Heat conducting medium flow rate |

15~45l/min 6bar max |

| Heating capacity |

2.5kW |

2.5kW |

2.5kW |

2.5kW |

3.5kW |

3.5kW |

| Cooling capacity |

3kW @-15℃ |

3kW @-15℃ |

5kW @-15℃ |

5kW @-15℃ |

2.5kW @-35℃ |

2.5kW @-35℃ |

Rated test conditions for all equipment: dry bulb temperature: 20℃; wet bulb temperature: 16℃. Inlet water temperature: 20℃; outlet water temperature: 25℃.

ETCU Heat Exchange Chiller Series

Adopting compressor-free refrigeration system

temperature control range is: 5℃~+90℃

temperature control accuracy: ±0.05℃

| Model |

ETCU-005W |

ETCU-015W |

ETCU-030W |

ETCU-050W |

ETCU-100W |

ETCU-200W |

ETCU-300W |

| Temperature range |

Cooling water temperature +5℃~90℃ |

| Temperature control accuracy |

±0.05℃(Steady state outlet temperature) |

| Cooling water temperature |

7℃~30℃ Cooling water flow is controlled by Siemens/Honeywell regulating valves |

| Cooling capacity |

5kW |

15kW |

30kW |

50kW |

100kW |

200kW |

300kW |

Rated test conditions for all equipment: dry bulb temperature: 20℃; wet bulb temperature: 16℃. Inlet water temperature: 20℃; outlet water temperature: 25℃.

AES Series Thermal Stream

Thermal Solutions for ATE testing

temperature control range is: -115℃~225℃

temperature control accuracy: ±0.1℃

| Model |

AES-4535

AES-4535W |

AES-6035

AES-6035W |

AES-8035

AES-8035W |

AES-A1035W |

AES-A1235W |

| Temperature range |

-40℃~225℃ |

-60℃~225℃ |

-80℃~225℃ |

-100℃~225℃ |

-120℃~225℃ |

| Temperature accuracy |

±0.1℃(Steady state outlet temperature) |

| Air requirements |

Air filter < 5um air oil content < 0.1um air temp and humidity:5℃-32℃ 0-50%RH |

| Air treatment capacity |

10m³/h-m³/h pressure 5bar-7.6bar |

Contact LNEYA technical engineer for model selection

chillers that control the processing temperature on the Fab equipments

advantages

- Efficient production stability and repeatability results;

- Using plate heat exchangers and pipeline heaters to improve cooling and heating rates;

- Very wide temperature range, no need to replace liquid medium;

- Fully enclosed system, extending the lifespan of thermal conductive liquids;

- Adopting magnetic drive pump, there is no problem of shaft seal leakage;

- High temperature cooling technology, directly start the compressor to cool down at 300 ℃.

Variable frequency pump can adjust circulating hydraulic pressure and flow

Heating function

Due to the use of heat generated during heating, circulating heating can be achieved without the need for a heater.

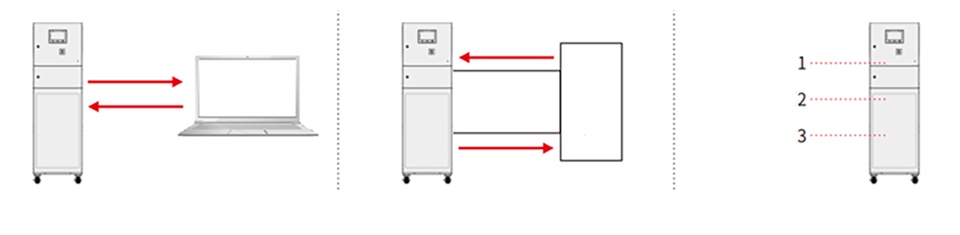

Communication function

Standard equipment includes serial communication (RS232C, RS485) and contact input/output. Can communicate with customer devices or build systems.

client output signal

Customized Chiller Solutions

Recommended products

Temperature Control :-120℃~350℃

Temperature control for high pressure reactor;Double-layer glass reactor;Double-layer reactor;Microchannel Reactor;Distillation system;Material aging test;Vacuum chamber etc.

Temperature Control: -40℃~100℃

Temperature simulation for vehicle quality test: battery life test, fuel injector/motor test bench, airbag test, component test bench, etc. It can simulate the external environmental conditions in the climate chamber or replace the internal system, which can create the necessary actual temperature conditions for the test bench.

Temperature Control: -85℃~250℃

Suitable for semiconductor process wet washing, photolithography, etching, chemical meteorological deposition, physical meteorological deposition, and the electronics industry (photolithography process)

Accept Customized Outdoor Chiller and Indoor Chiller

rovide 7 * 24 free consultation & comprehensive solutions

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier