Temp Flow Control+Test Chamber

KRYCH -40℃~100℃Environmental Chamber Provides -45°C~100°C

Large observation window allows real-time observation of test conditions in the box and timely adjustments.

Product data download

Temperature control Chamber for during testing

Integrated system provides new energy power battery samples

High temperature, low temperature, flow and pressure control and other needs

Environmental chamber provides -45°C~100°C

Advantage

High heat exchange density

Small footprint

Ensure battery core temperature is low

Better uniformity

Effectively extend battery life

Improve reliability and security

Reduce maintenance costs

The battery is tested for stability and safety in a high temperature chamber with natural convection or forced ventilation.

The double-layer high and low temperature chamber is a high and low temperature test device for explosive samples. It is currently mainly used in the new energy battery industry. It can directly complete high and low temperature charging and discharging, or high and low temperature storage, for battery cells, modules, and PACKs in the test chamber. In the event of battery failure, explosion-proof pressure relief and fire protection devices are added.

Parameter

Model |

GD-9000-2-B1-KRYCH-4A15W |

GD-9000-2-B1-KRYCH-475W |

GD-9000-2-B1-KRYCH-4A10W |

GD-1000-B1-KRYCH-475 |

|||||

| Temperature range | -40℃~100℃ Antifreeze |

-40℃~100℃ Chamber |

-40℃~100℃ Antifreeze |

-40℃~100℃ Chamber |

-40℃~100℃ Antifreeze |

-40℃~100℃ Chamber |

-40℃~100℃ Antifreeze |

-40℃~100℃ Chamber |

|

| Antifreeze flow control | 1L/min~40L/min | 1L/min~25L/min | 1L/min~25L/min | 1L/min~10L/min | |||||

| Antifreeze flow control accuracy | ±0.2L/min | ±0.2L/min | ±0.2L/min | ±0.2L/min | |||||

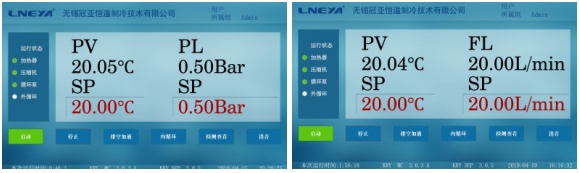

| Antifreeze pressure | Measure and display the inlet and outlet pressure and display the pressure on the touch screen | ||||||||

| Test chamber size (W*H*D) |

Upper cavity (cm) | 220*322*120 | 220*322*120 | 220*322*120 | Single cavity: 100*100*100 | ||||

| Lower cavity (cm) | 220*322*110 | 220*322*110 | 220*322*110 | ||||||

| Heating capacity (kW) | 15 | 14 | 7.5 | 14 | 10 | 14 | 7.5 | 6 | |

| Cooling capacity (kW) Antifreeze |

135℃ | 15 | 7.5 | 10 | 7.5 | ||||

| 20°℃ | 15 | 7.5 | 10 | 7.5 | |||||

| 0℃ | 15 | 7.5 | 10 | 7.5 | |||||

| -20℃ | 10 | 4.5 | 6 | 4.5 | |||||

| -35℃ | 4 | 1.8 | 2.5 | 1.8 | |||||

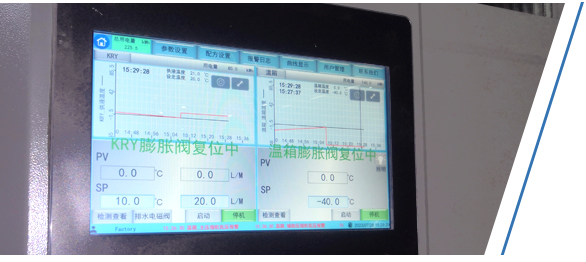

| Test chamber | Heating rate | 25~+100℃≥±2℃/Min (no load, full-time average) (5~25℃ can be customized) | |||||||

| Cooling rate | 25~-40℃≥1℃/Min (no load, average over the whole process) (5~25℃ can be customized) | ||||||||

| Antifreeze temperature control accuracy | ±0.1℃ | ||||||||

| Temperature uniformity of high and low temperature chambers | ≤±1℃ (no load) | ||||||||

| Circulation air volume | 5000m³/h | 2500m³/h | |||||||

| Control method | Segmented fuzzy PID algorithm control | ||||||||

| Communication protocol interface | CAN/TCP/RS485 | ||||||||

| Internal temperature feedback of the equipment | Equipment box internal temperature, refrigeration system condensation temperature, compressor suction temperature, cooling water temperature (water cooling equipment has) | ||||||||

| High temperature cooling module | Can cool down from high temperature 100℃ | ||||||||

| Circulation pump | Magnetic drive pump | ||||||||

| compressor | Brand inverter compressor | ||||||||

| Evaporator | Plate/Fin Heat Exchanger | ||||||||

| Refrigeration accessories | Emerson/Danfoss brand filter drier, oil separator, etc. | ||||||||

| Throttling method | Electronic expansion valve | ||||||||

| Refrigerant | R125/R404A | ||||||||

| Safety protection | Phase sequence failure protector, refrigerator overload protection; high pressure switch, overload relay, thermal protection device and other safety protection functions. | ||||||||

| Water-cooled condenser | Jacket/shell and tube heat exchanger | ||||||||

| Operation panel | 10-inch color touch screen, temperature curve display\EXCEL data export | 7-inch color touch screen, temperature curve display\EXCEL data export | |||||||

| Internal reserved antifreeze interface | ZG3/4 | ZG3/8 | |||||||

| Cooling water @20℃ | 25m3/H | 20m3/H | 20m3/H | 7m3/H | |||||

| Overall dimensions (W*H*D)cm | 240*560*285 | 240*560*285 | 240*560*285 | 120*205*205 | |||||

| Inner bottom plate load bearing | 1500kg | 1500kg | 1500kg | 120kg | |||||

| Weight | 4600kg | 4200kg | 4200kg | 600kg | |||||

| Power supply | 380V 50HZ | ||||||||

| Insulation material | Glass fiber wool & polyurethane | ||||||||

| Inner box material | SUS304 stainless steel brushed plate | ||||||||

| Outer box material | Cold rolled steel plate + plastic spraying | ||||||||

| Execution meets standards | GB/T 2423.1;GB/T 2423.2;GB/T 2423.3;GB/T 2423.4;GB/T 5170.2;GB/T 5170.5;GB/T 11158;GB/T 10589;GB/T 10592; GB/T 10586;IEC 60068 | ||||||||

Specially developed for new energy vehicle battery packs

Suitable for hot and cold shock at various temperatures

It can provide antifreeze system for high-temperature and low-temperature tests for automobile battery packs, and can also be used as a refrigeration and heating system for hot and cold shock.

The double-layer high and low temperature chamber is used as a high and low temperature testing device for power battery samples. It is currently mainly used in the new energy battery industry. It can directly complete high and low temperature charge and discharge for battery cells, modules, and PACKs in the test chamber, or store high and low temperatures. Functions such as explosion-proof pressure relief and fire protection devices are added under the conditions when the battery fails to be tested.

Upper and lower double-layer box design

Antifreeze battery cooling system included

The two-box system operates completely independently

working principle

The variable frequency pump can adjust the circulating hydraulic pressure and flow rate to achieve high-precision control of the total range from 5% to 100%.

(The output pressure and flow rate of the circulating fluid can be set on the operation panel. Even under various customer piping conditions, without bypass piping adjustment, the set output pressure can be automatically controlled by the variable frequency pump. This can reduce the power consumption of the pump.)

The refrigeration unit mainly includes refrigeration compressor, condenser, oil separator, intermediate heat exchanger, internal circulation fan of the box, dry filter, condenser, evaporator, throttling mechanism, expansion tank, electrical control, etc.

The liquid refrigerant in the evaporator of the unit exchanges with the circulating air inside the box. The temperature rises and changes from liquid to gas. It is sucked into the suction port of the compressor. The high-temperature and high-pressure refrigerant gas compressed by the compressor first passes through The oil separator separates the refrigeration oil carried during the compression process, and then enters the condenser. After exchanging heat with ambient air or cooling water, it changes from high-temperature and high-pressure gas to high-pressure and normal-temperature liquid. The high-pressure and normal-temperature refrigerant liquid passes through the dry filter and then is throttled and decompressed by the expansion valve, that is, it changes from high-pressure liquid to low-pressure liquid. Low-pressure liquid (lower boiling point) enters the evaporator of the unit, and the cooling energy is brought to the inside of the box through circulating air to achieve refrigeration.

Equipment details

Cabinet design

Display operation

Stable operation

The sales interface of the whole machine has strong adaptability, one is better than N units

recommend products

MD Series Chuck

-75℃ to 225°C Model MD-708 MD-712 MDL-708 Temp. Range -75℃~225℃ -75℃~225℃ -75℃~225℃ Temperature control accuracy ±0.1℃ ±0.1℃ ±0.1℃ temperature uniformity ±1℃ ±1℃ ±1℃ Flatness ±50um ±50um ±50um Tablet Size 200mm diameter d…

YQH 0℃~-75℃

Suitable for the recovery of various volatile VOCs gases; Fast cooling, high efficiency, meeting different condensing temperature requirements, low temperature can reach -75 ° C It mainly comes from the cleaning, glue …

FLT-100℃~90℃

Single channel air-cooled cooler, mainly designed for etching machines. It is used to provide independent temperature control for the chamber sid…

FLTZ -45℃~90℃

Heating method within 40 ℃ adopts a compressor hot gas heating fully enclosed design, and the machine operates continuously for 24 hours The semiconductor temperature control device Chiller is mainly used for p…

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier