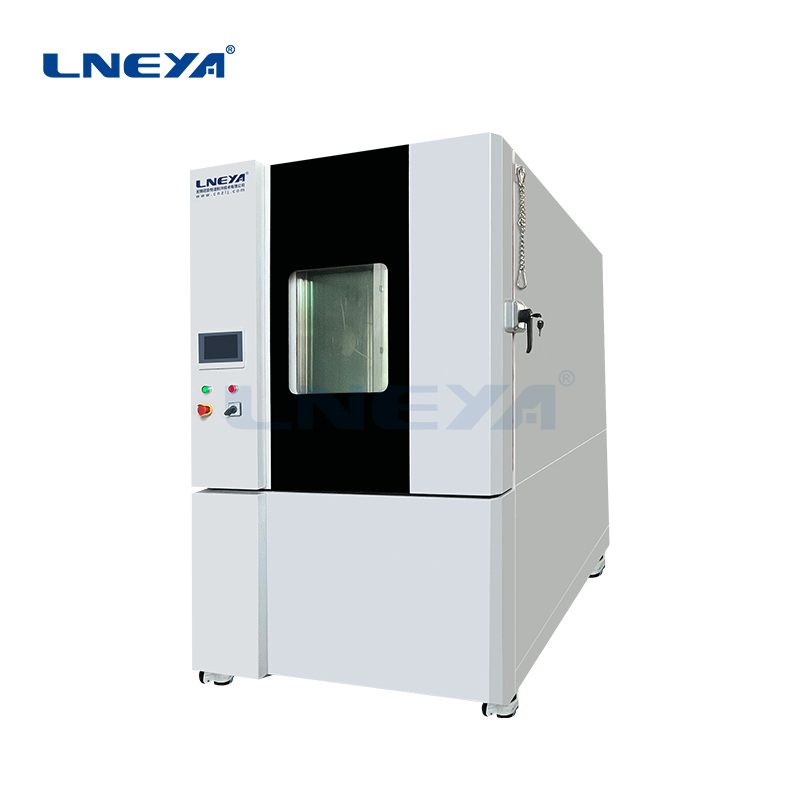

Two-box impact test chamber

-40℃~0℃ & 60℃~150℃- Heating rate of preheating zone(No load) 5 ℃/min (customizable for 10-25 ℃)

- Cooling rate of pre cooling zone (No load) 2 ℃/min (customizable for 5-25 ℃)

- Pre cooling area Pre cooling range-10℃~-55℃

- Preheating area preheating range+60℃~+180℃

- Temperature fluctuation≤1℃

The test basket of the double-chamber cooling and heating shock test chamber is mobile when conducting high and low temperature shock tests. The high and low temperature shock conversion is mainly completed by moving the test basket up and down in the high temperature zone and the low temperature zone. The impact recovery time of the double-chamber type is shorter than that of the three-chamber type.

Configuration Details

| Model | GD-200-2-B-CJ | GD-400-2-B-CJ | |

| Inner box size (W*H*D)cm |

60*60*60 | 90*65*70 | |

| Shock temperature range | Low temperature | -40~0℃ | |

| High temperature | +60~+150℃ | ||

| Preheating zone heating rate | (no load) 5℃/min (10~25℃ can be customized) | ||

| Precooling zone cooling rate | (no load) 2℃/min (5~25℃ can be customized) | ||

| Precooling area precooling range | -10~-55℃ | ||

| Preheating range of preheating zone | +60~+180℃ | ||

| Dwell time | ≥30min | ||

| Recovery time | ≤5min Recover to within ±2℃ | ||

| Temperature fluctuation | ≤1℃ | ||

| Dwell time | ≥30min | ||

| Conversion time | ≤10S | ||

| Window size (cm) | 300*450 | ||

| Refrigerant | R404A/R23 | ||

| Heater | Electric heating | ||

| Air-cooled condenser | Fin heat exchanger | ||

| Water-cooled condenser | Jacket/shell and tube heat exchanger | ||

| Air circulation | Extended shaft motor, stainless steel centrifugal fan blades | ||

| Cooling method | Cascade Refrigeration | ||

| Compressor | Brand inverter compressor | ||

| Control method | Segmented fuzzy PID algorithm control | ||

| Communication protocol interface | TCP/RS485 (CAN can be customized) | ||

| Operation panel | 7-inch color touch screen, temperature curve display\EXCEL data export | ||

| Sensor | PT100A grade platinum resistor | ||

| Protective devices | Heater dual temperature protection, refrigeration system protection and electrical overcurrent and overload protection, etc. | ||

| Outer box size (W*H*D)cm |

149*219*257 | 179*239*257 | |

| Power supply | 380V 50HZ | ||

| Insulation material | Glass fiber wool & polyurethane | ||

| Inner box material | SUS304 stainless steel | ||

| Outer box material | Cold rolled steel plate + plastic spraying | ||

| Execution meets standards | GB/T 2423.1、GB/T 2423.2、GJB 150.3A、GJB 150.4A、GB/T 5170 | ||

You may also be interested in these products

SUNDI Z Frequency Conversion Series

WHATSAPP WECHAT Ultra high temperature cooling technology can directly cool from a high temperature of 300℃[because only the heat transfer medium in the expansion…

SUNDI -10℃~150℃

Fully enclosed system, single medium completes refrigeration and heating -120~350℃ ±0.5℃ AC 380V 50HZ 8kW max Ultra high temperature cooling technology can directly cool from a hi…

SUNDI -80℃~250℃

● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control ● Maximum process stability and reproducibility ● Adop plate heat exchager, Pipeline heating, the fastest he…

SUNDI-320/320W

Fully enclosed system, single medium completes refrigeration and heating -120~350℃ ±0.5℃ Ultra-high Temperature Cooling Technology Can Directly Cool Down From 300℃ High Temperature. Bec…

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier