Single Fluid Cryogenic Chiller

LJ -45℃~-10℃- Cooling capacity @-20℃12kW~360kW

- Expansion tank50L~400L

- Power range12kW~270kW

- RefrigerantR404A/R507C

- Weight800KG~5000KG

- Place of OriginChina

Product data download

Pharmaceutical & chemical industry

single fluid low temperature refrigeration unit

Fast cooling and low cooling temperature

temperature control

-5~-150°C

cooling method

Water Cooling

LNEYA specializes in the production of single-fluid cryogenic chillers. The refrigeration temperature ranges from -150°C to -5°C, which can meet the needs of different refrigeration temperatures. The company developed a direct-cooled ultra-low temperature chiller, using international brand compressors Carrier, using automatic cascade refrigeration mode and mixed refrigerants, within 3 minutes can be refrigerated to minus 120°C.

Offer machine installation and system test, users only need to finish the installation of refrigerant and cooling water.

Widely used in chemical, pharmaceutical, biochemical and other industries in the field of low temperature reaction, refrigeration speed, safety and reliability.

Configuration Details

| Model | LJ-6W | LJ-10W | LJ-15W | LJ-20W | LJ-30W | LJ-40W | LJ-60W | LJ-90W | LJ-120W | LJ-180W |

| Temperature Range | -45°C~ -10°C | |||||||||

| Cooling Capacity At -35°C |

6kw | 10kw | 15kw | 20kw | 30kw | 40kw | 60kw | 90kw | 120kw | 180kw |

| 5160Kcal/h | 8600Kcal/h | 12900Kcal/h | 17200Kcal/h | 25800Kcal/h | 344000Kcal/h | 51600Kcal/h | 77400Kcal/h | 103200Kcal/h | 154800Kcal/h | |

| Circulation Pump Info | 6.6m³/h | 9m³/h | 15m³/h | 15m³/h | 25m³/h | 25m³/h | ||||

| 2.5bar max | 2.5bar max | 2.5bar max | 2.5bar max | 2.5bar max | 2.5bar max | |||||

| Inlet&outlet connection size | DN-25 PN-10 |

DN-32 PN-10 |

DN-40 PN-10 |

DN-40 PN-10 |

DN-50 PN-10 |

DN-50 PN-10 |

DN-50 PN-10 |

DN-65 PN-10 |

DN-65 PN-10 |

DN-80 PN-10 |

| Cooling Water at 30 degree | 8m³/h | 10m³/h | 16m³/h | 20m³/h | 25m³/h | 30m³/h | 38m³/h | 55m³/h | 70m³/h | 100m³/h |

| Cold Storage tank (optional) | 100L | 150L | 230L | 260L | 300L | 400L | 600L | 2200L | 3000L | 4000L |

| Expansion tank(standard) | 50L | 80L | 150L | 180L | 200L | 250L | 400L | / | // | |

| Compressor | Dorin semi-closed compressor | Dorin compressor/HANBELL、Fusheng、Bitzer screw compressor | ||||||||

| Operation Panel | 7-inch color touch screen display, temperature curve record | |||||||||

| Control System | Standard: Single-chip micocomputer controller; Stepping control; Set temperature difference of refrigeration on & off PLC&Module |

|||||||||

| Closed Circulation System | The whole system is a full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supplement oil automatically at low temperature | |||||||||

| Circulation Pump | LNEYA Mangetic Pump | |||||||||

| Evaporator | Plate heat exchanger | |||||||||

| Condenser | Casing type water-cooled condenser / tube-type water-cooled condenser | |||||||||

| Intermediate heat exchanger | Plate heat exchanger | |||||||||

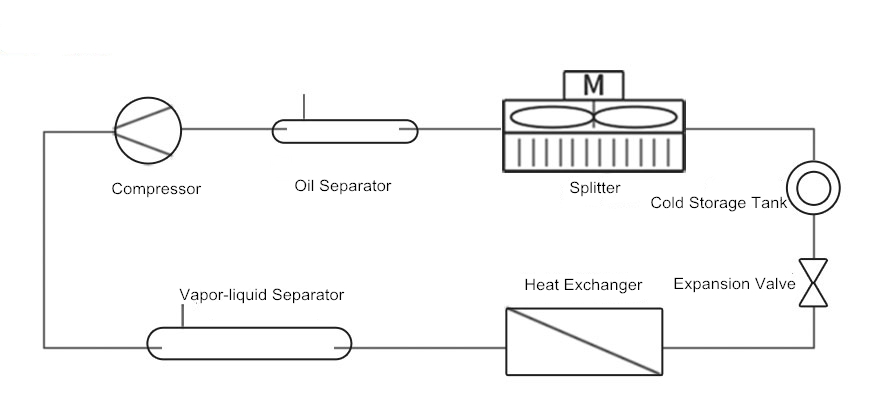

| Refrigeration accessory | Oil separators, drying filters, expansion valves, refrigeration solenoid valves, pressure control, mirrors, etc. all use Emerson / Danfoss and other brands | |||||||||

| Electric | AC contactors, intermediate relays, circuit breakers, thermal relays, etc. are Schneider / ABB brand | |||||||||

| Refrigerant | R404A | |||||||||

| Secondary refrigerant | No corrosive liquid, ethanol water, heat transfer oil etc. | |||||||||

| Safety Protection | High pressure protect; water supply cut-off protection; over-current protection; leakage protection; sequential and phase failure protection; High temperature protection; Sensor Failure protection; Liquid low level protection etc. multi-safety protection | |||||||||

| Level Indicator | Adopt glass liquid level indication | |||||||||

| Piping material | Expansion tank, cold storage tank and circulation pipeline are all made of SUS304 | |||||||||

| Case material | Channel steel + square tube + cold rolled plate sealing plate spray 7035 | |||||||||

| Dimension cm | 100*150*185 | 100*150*185 | 200*145*205 | 200*145*205 | 250*145*225 | 250*145*225 | 300*160*225 | 350*160*245 | 400*160*245 | 500*200*260 |

| Power | 14kW | 17kW | 25kW | 34kW | 52kW | 65kW | 100kW | 127kW | 167kW | 247kW |

| dB | within 75dB | within 80 dB | within 90 dB | |||||||

| Weight (kg) | 800 | 950 | 1100 | 1350 | 1500 | 1800 | 2400 | 3100 | 3600 | 5000 |

| Optional | Optional outside touch screen display controller (separated), the communication line distance is 10 meter | |||||||||

| Optional explosion-proof touch screen control system (ExdeIIBT4), the communication line distance is 15 meter | ||||||||||

Product Description

1.Temperature ranges from -5℃ ~ -150℃, can meet different temperature

2. Famous brand semi-closed piston compressor, semi-closed bipolar piston compressor, semi-hermetic screw compressor, main brand are BOCK. Bitzer, Copeland, Handbell, fusheng; Plate heat exchanger, Small volume, High efficiency

3. Top imported cold controller; Generator cooling water circuit uses intermediate heat exchanger, improve system reliability and safety.

4. DANFOSS electronic expansion valve, high precision control;

5. Adopt Siemens PLC S7-200/300, LNEYA touch screen, automatic control, temperature curve display, temperature record U disk, fault alarm;

6. Offer machine installation and system test, users only need to finish the installation of refrigerant and cooling water.

Applications

Widely used in high-tech industries such as petrochemical, pharmaceutical and medical, biochemical engineering, aerospace industry, semiconductor manufacturing, and university research institutes.

REQUEST A QUOTE

recommend products

LN -60°C~ -10°C

适用范围 Product Features 产品参数 Product Parameter 行业应用 APPLICATION 航空航天材料|试验装置控温解决方案 在航空航天领域,材料的性能直接关系到飞行器的安全、可靠性和…

LD -80°C~ -30°C

1.Temperature ranges from -5℃ ~ -150℃, can meet different temperature2. Famous brand semi-closed piston compressor, semi-closed bipolar piston compressor, semi-hermetic screw compressor, main brand are BOCK. Bitzer, Cop…

SLJ -110℃~-150℃

1.Temperature ranges from -5℃ ~ -150℃, can meet different temperature2. Famous brand semi-closed piston compressor, semi-closed bipolar piston compressor, semi-hermetic screw compressor, main brand are BOCK. Bitzer,…

CDLJ -110°C~ -50°C

5kW Chiller; 10kW Chiller; 30kW Chiller; 60kW Chiller; 120kW Chiller Widely used in chemical, pharmaceutical, biochemical and other industries in the field of low temperature reaction, refrigeration speed, safety and reliabil…

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier