Product Description

- ● Working temperatures from -120°C to +350°C

- ● Previously unachievable performance

- ●Intelligent temperature control

- ● Maximum process stability and reproducibility

- ● Adop plate heat exchager, Pipeline heating, the fastest heating and cooling rates.

- ● High cooling power from 0.5 to 1200kW

- ● Large temperature range without fluid change

- ● Closed system, extend thermal fluid lifetime

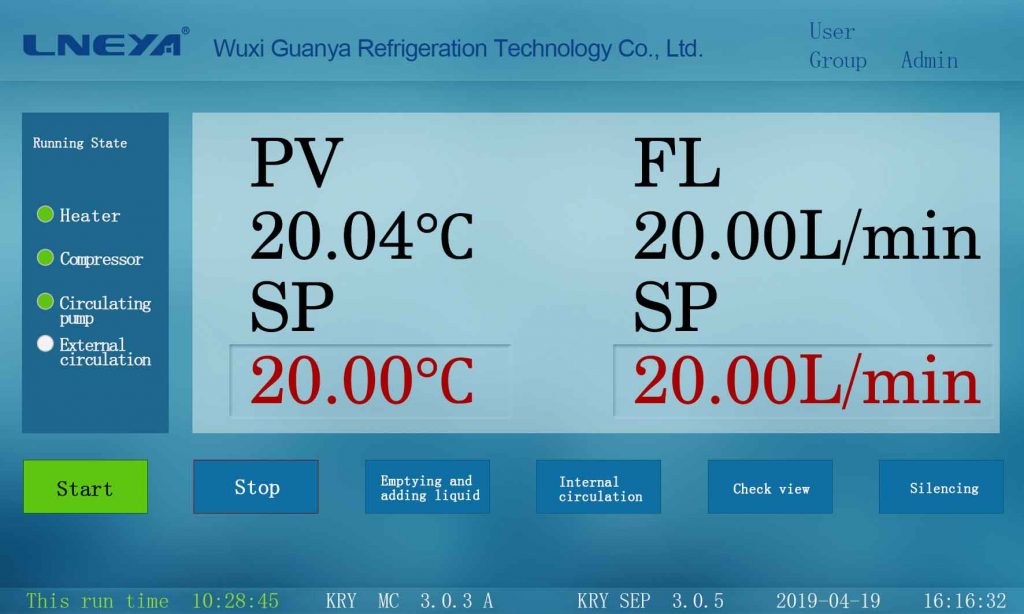

- ● 7-inch, 10-inch color TFT touch screen display

- ● Comprehensive warning and safety functions

- ● Rapid cooling down from high temperature (from 300 °C)

- ● Use magnetic drive pump, solve the circulation pump leakage

| SUNDI – | 625 625W |

635 635W |

655 655W |

675 675W |

6A10 6A10W |

6A15W | 6A25W | 6A38W | 6A60W | |

| Temp. range | -60℃~+250℃ | |||||||||

| Control Mode | Feedback PID + Our special dynamic control calculation, PLC controller | |||||||||

| Temp. control | process temp. control and jacket temp. control model | |||||||||

| Temp. difference | Set or control the temperature difference between jacket oil and raw material process | |||||||||

| Program Editor | 5 programs, each program can edit 40 steps. | |||||||||

| Communication Portocol | MODBUS RTU Protocol,RS485 interface | |||||||||

| Material temp. feedback | PT100 OR 4~20mA or communication(normal: PT100) | |||||||||

| Temp. feedback | The temp. of three points: the inlet and outlet of equipment, reactor material temp.(external temp. sensor) | |||||||||

| Medium temp. acccuracy | ±0.5℃ | |||||||||

| Reaction material temp. acccuracy | ±1℃ | |||||||||

| Heating power kW | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 | |

| Cooling capacity kW at | 250℃ | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 |

| 100℃ | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 | |

| 20℃ | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 | |

| -20℃ | 2 | 3 | 4.8 | 6 | 8.2 | 12 | 25 | 38 | 56 | |

| -40℃ | 0.95 | 1.45 | 2.3 | 3.1 | 4.8 | 7.8 | 18 | 23 | 31 | |

| -55℃ | 0.25 | 0.5 | 0.75 | 0.9 | 1.5 | 2.8 | 6 | 8 | 11 | |

| Circulation pump max L/min bar |

20 | 35 | 35 | 50 | 60 | 110 | 150 | 200 | 250 | |

| 1.2 | 1.2 | 1.2 | 1.2 | 1.5 | 1.5 | 1.5 | 1.5 | 2.5 | ||

| pump | Magnetic drive pump | |||||||||

| Compressor | Tecumseh closed compressor | Dorin semi-closed compressor | ||||||||

| Expansion valve | Electronic expansion valve | |||||||||

| Evaporator | Plate heat exchanger | |||||||||

| Operation Panel | 7-inch touch screen,show temp curve\EXCEL data output | |||||||||

| Safety protection | Self-diagnosis function; freezer overload protection; high pressure switch, overload relay,thermal protection device, liquid low level protection, high temperature protection and temperature fault protection. | |||||||||

| Closed circulation system | The whole system is full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supply oil automatically at low temperature. | |||||||||

| Refrigerant | R404A/R23 | |||||||||

| Connection size | ZG1/2 | ZG3/4 | ZG3/4 | ZG1 | ZG1 | ZG1 | DN32 PN10 | DN40 PN10 | DN50 PN10 | |

| Water-cooled type W(cooling water@20℃) | 900L/H 1.5bar~4bar |

1200L/H 1.5bar~4bar |

1800L/H 1.5bar~4bar |

2100L/H 1.5bar~4bar |

3000L/H 1.5bar~4bar |

4000L/H 1.5bar~4bar |

8.5m³/H 1.5bar~4bar |

14m³/H 1.5bar~4bar |

20m³/H 1.5bar~4bar |

|

| Dimension cm | 55*70*175 | 55*70*175 | 55*70*175 | 65*85*185 | 65*85*185 | 80*120*185 | 150*100*185 | 200*145*205 | 200*145*205 | |

| Weight kg | 205 | 225 | 300 | 340 | 380 | 380 | 980 | 1350 | 1580 | |

| Power 380V 50HZ | 5kW max | 7.5kW | 11kW | 14kW | 19kW | 26.5kW | 49kW | 73kW | 103kW | |

Working Principle

Ultra high temperature cooling technology can directly cool from a high temperature of 300℃[because only the heat transfer medium in the expansion chamber contacts with oxygen in the air (and the temperature of the expansion tank is between normal temperature and 60℃), which can reduce the risk of heat transfer medium being oxidized and absorbing water in the air. At high temperature, no heat conducting medium evaporates, and continuous temperature control of – 80℃ ~ 190℃, – 70℃ ~ 220℃, – 88℃ ~ 170℃, – 55℃ ~ 250℃ and – 30℃ ~ 300℃ can be realized without pressurization.

Application: Various Reactors (Microchannels, Glass, Jacketed Reactors, etc.), Distillation or Extraction System, Laboratory, University, Research Institute, Aerospace, Automotive Industry, Semiconductor and Electrical Test, Chemical, Pharmaceutical, Petrochemical, Biochemical, Medical, Hospital, R&D Workshop, Aerospace, Biological and Other Industries.

Displays Various Information:

1. Displays all the kind of process control temperatures.

2. Shows the liquid level of the heat conducting medium in the expansion vessel.

3. Shows indication for refrigeration system working.

4. Shows indication for heater working.

5. Shows indication for circulation pump working.

6. Displays the temp. control ( materials temp. control pattern, heat conducting medium temp. control ).

7. The temp. upper limit, lower limit control can be set.

8. The temp. difference between jacket & reactor material can be set.

9. Shows the alarm to add the liquid when it is empty.

10. The refrigeration compressor can be set to operate manuallyor automatically.

You may also be interested in these products

SUNDI Z Frequency Conversion Series

WHATSAPP WECHAT Ultra high temperature cooling technology can directly cool from a high temperature of 300℃[because only the heat transfer medium in the expansion…

SUNDI -10℃~150℃

Fully enclosed system, single medium completes refrigeration and heating -120~350℃ ±0.5℃ AC 380V 50HZ 8kW max Ultra high temperature cooling technology can directly cool from a hi…

SUNDI -80℃~250℃

● Working temperatures from -120°C to +350°C ● Previously unachievable performance ●Intelligent temperature control ● Maximum process stability and reproducibility ● Adop plate heat exchager, Pipeline heating, the fastest he…

SUNDI-320/320W

Fully enclosed system, single medium completes refrigeration and heating -120~350℃ ±0.5℃ Ultra-high Temperature Cooling Technology Can Directly Cool Down From 300℃ High Temperature. Bec…

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier