FLT -100℃~90℃

semiconductor production process water chiller- Temperture accuracy±0.1℃

- Flow control12~45/min

- TypeFrequency Variable Series

- Power range380V

FLTZ -100℃~+90℃ Low Temperature Cascade Refrigeration Series

| Model | FLTZ-002 | FLTZ-003 | FLTZ-004 | FLTZ-006 | FLTZ-008 | FLTZ-010 | FLTZ-015 |

| FLTZ-002W | FLTZ-003W | FLTZ-004W | FLTZ-006W | FLTZ-008W | FLTZ-010W | FLTZ-015W | |

| Temperature range | 5℃~90℃ | ||||||

| Temperature control accuracy | ±0.05℃(Steady state outlet temperature) | ||||||

| Cooling capacity @10℃ | 6kW | 8kW | 10kW | 15kW | 20kW | 25kW | 40kW |

| Internal circulating fluid volume | 4L | 5L | 6L | 8L | 10L | 12L | 20L |

| Expansion tank volume | 10L | 10L | 15L | 15L | 20L | 25L | 35L |

| Refrigerant | R410A | ||||||

| Refrigerating medium | Silicone oil, fluorinated liquid, polyol aqueous solution, DI, etc. (DI temp needs to be controlled above 10 ℃) | ||||||

| Connection size | ZG1/2 | ZG1/2 | ZG3/4 | ZG3/4 | ZG3/4 | ZG1 | ZG1 |

| Cooling water connection size | ZG1/2 | ZG1/2 | ZG3/4 | ZG1 | ZG1 | ZG1 | ZG1 1/8 |

| Cooling water flow @20℃ | 1.5m³/h | 2m³/h | 2.5m³/h | 4m³/h | 4.5m³/h | 5.6m³/h | 9m³/h |

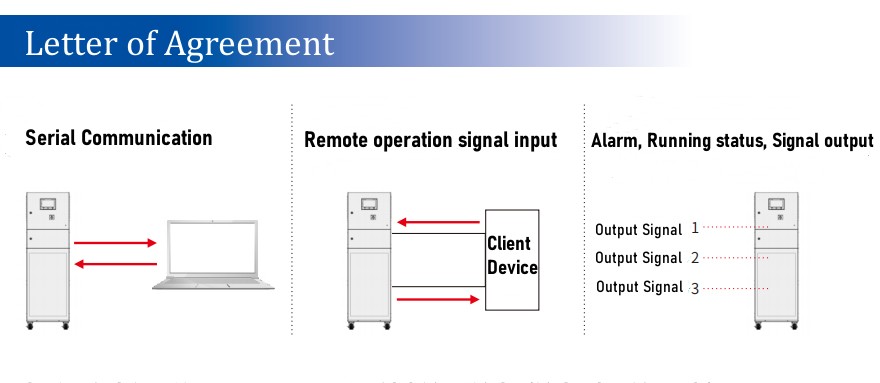

| Process temperature control | The remote target temperature can be controlled by combining the self created model free self built tree algorithm and cascade algorithm |

||||||

| Dimension cm | 950*380*1055 | 950*380*1055 | 950*380*1055 | 980*430*1400 | 980*430*1400 | 1080*600*1500 | 1080*600*1500 |

| Model | FLTZ-1002W | FLTZ-1004W |

| Temperature range | -100℃~+90℃ | |

| Temperature control accuracy | ±0.05℃(Steady state outlet temperature) | |

| Flow control | 7~25L/min | 12~45L/min |

| Cooling capacityat-90℃ | 1.5kW | 3kW |

| Heating capacity | 3.5kW | 5.5kW |

| Internal circulating fluid volume | 5L | 8L |

| Expansion tank volume | 10L | 15L |

| Heat-conduction medium | Fluorinated liquid | |

| Connection size | ZG3/4 | ZG3/4 |

| Cooling water connection size | ZG3/4 | ZG1 |

| Cooling water@20℃ | 50L/min 2bar~7bar | 100L/min 2bar~7bar |

| Circuit breaker | 32A | 63A |

| Process temperature control | The remote target temperature can be controlled by combining the self created model free self built tree algorithm and cascade algorithm |

|

FLTZ -45℃~90℃

| Model | FLTZ-002 | FLTZ-003 | FLTZ-004 | FLTZ-006 | FLTZ-008 | FLTZ-010 | FLTZ-015 |

| FLTZ-002W | FLTZ-003W | FLTZ-004W | FLTZ-006W | FLTZ-008W | FLTZ-010W | FLTZ-015W | |

| Temperature range | 5℃~90℃ | ||||||

| Temperature control accuracy | ±0.05℃(Steady state outlet temperature) | ||||||

| Cooling capacity @10℃ | 6kW | 8kW | 10kW | 15kW | 20kW | 25kW | 40kW |

| Internal circulating fluid volume | 4L | 5L | 6L | 8L | 10L | 12L | 20L |

| Expansion tank volume | 10L | 10L | 15L | 15L | 20L | 25L | 35L |

| Refrigerant | R410A | ||||||

| Refrigerating medium | Silicone oil, fluorinated liquid, polyol aqueous solution, DI, etc. (DI temp needs to be controlled above 10 ℃) | ||||||

| Connection size | ZG1/2 | ZG1/2 | ZG3/4 | ZG3/4 | ZG3/4 | ZG1 | ZG1 |

| Cooling water connection size | ZG1/2 | ZG1/2 | ZG3/4 | ZG1 | ZG1 | ZG1 | ZG1 1/8 |

| Cooling water flow @20℃ | 1.5m³/h | 2m³/h | 2.5m³/h | 4m³/h | 4.5m³/h | 5.6m³/h | 9m³/h |

| Process temperature control | The remote target temperature can be controlled by combining the self created model free self built tree algorithm and cascade algorithm |

||||||

| Dimension cm | 950*380*1055 | 950*380*1055 | 950*380*1055 | 980*430*1400 | 980*430*1400 | 1080*600*1500 | 1080*600*1500 |

| Model | FLTZ-202 | FLTZ-203 | FLTZ-204 | FLTZ-206 | FLTZ-208 | FLTZ-210 | FLTZ-215 |

| FLTZ-202W | FLTZ-203W | FLTZ-204W | FLTZ-206W | FLTZ-208W | FLTZ-210W | FLTZ-215W | |

| Temperature range | -25℃~90℃ | ||||||

| Temperature control accuracy | ±0.05℃(Steady state outlet temperature) | ||||||

| Flow control | 10~25L/min | 15~45L/min | 25~75L/min | ||||

| Cooling capacity @-15℃ | 2kW | 3kW | 3.8kW | 6kW | 7.6kW | 10kW | 15kW |

| Internal circulating fluid volume | 4L | 5L | 6L | 8L | 10L | 12L | 20L |

| Expansion tank volume | 10L | 10L | 15L | 15L | 20L | 25L | 35L |

| Refrigerant | R404A | ||||||

| Refrigerating medium | Silicone oil, fluorinated liquid, glycol solution etc | ||||||

| Connection size | ZG1/2 | ZG1/2 | ZG3/4 | ZG3/4 | ZG3/4 | ZG1 | ZG1 |

| Cooling water connection size | ZG1/2 | ZG1/2 | ZG3/4 | ZG3/4 | ZG1 | ZG1 | ZG1 1/8 |

| Cooling water flow @20℃ | 1.2m³/H | 1.6m³/H | 2.6m³/H | 3.6m³/H | 5.5m³/H | 7m³/H | 10.2m³/H |

| Process temperature control | The remote target temperature can be controlled by combining the self created model free self built tree algorithm and cascade algorithm |

||||||

| Dimension cm | 950*380*1055 | 950*380*1055 | 950*380*1055 | 980*430*1400 | 980*430*1400 | 1080*600*1500 | 1080*600*1500 |

| Model | FLTZ-402 | FLTZ-403 | FLTZ-404 | FLTZ-406 | FLTZ-408 | FLTZ-410 | FLTZ-415 |

| FLTZ-402W | FLTZ-403W | FLTZ-404W | FLTZ-406W | FLTZ-408W | FLTZ-410W | FLTZ-415W | |

| Temperature range | -45℃~90℃ | ||||||

| Temperature control accuracy | ±0.05℃(Steady state outlet temperature) | ||||||

| Flow control | 10~25L/min 5bar max | 15~45L/min 5bar max | 25~75L/min 5bar max | ||||

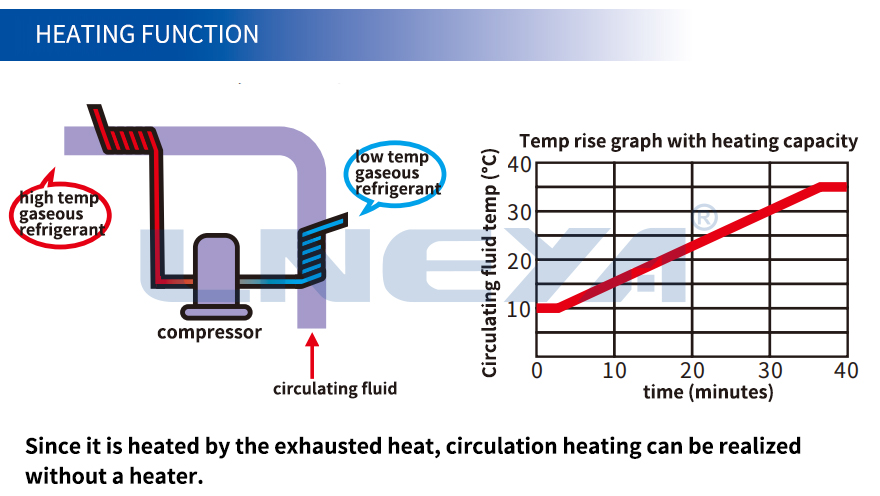

| Heating | Using compressor heating, prevent condenser frosting technology | ||||||

| Cooling capacity @-35℃ | 1kW | 1.4kW | 1.8kW | 2.5kW | 3.3kW | 5kW | 8kW |

| Internal circulating fluid volume | 4L | 5L | 6L | 8L | 10L | 12L | 20L |

| Expansion tank volume | 10L | 10L | 15L | 15L | 20L | 25L | 35L |

| Refrigerant | R404A | ||||||

| Refrigerating medium | Silicone oil, fluorinated liquid, glycol solution etc | ||||||

| Connection size | ZG1/2 | ZG1/2 | ZG3/4 | ZG3/4 | ZG3/4 | ZG1 | ZG1 |

| Cooling water connection size | ZG1/2 | ZG3/4 | ZG3/4 | ZG1 | ZG1 | ZG1 | ZG1 1/8 |

| Cooling water flow @20℃ | 1.5m³/H | 2.4m³/H | 3.5m³/H | 5m³/H | 5.5m³/H | 6m³/H | 8m³/H |

| Process temperature control | The remote target temperature can be controlled by combining the self created model free self built tree algorithm and cascade algorithm |

||||||

| Dimension cm | 950*380*1055 | 950*380*1055 | 950*380*1055 | 980*430*1400 | 980*430*1400 | 1080*500*1500 | 1080*500*1500 |

Heat exchange Chiller Compressor-free

| Model | ETCU-005W | ETCU-015W | ETCU-030W | ETCU-050W | ETCU-100W | ETCU-200W | ETCU-300W |

| Temperature range | Cooling water temperature +5℃~90℃ | ||||||

| Temperature control accuracy | ±0.05℃(Steady state outlet temperature) | ||||||

| Cooling water temperature | 7℃~30℃ Cooling water flow is controlled by Siemens/Honeywell regulating valves | ||||||

| Cooling capacity | 5kW | 15kW | 30kW | 50kW | 100kW | 200kW | 300kW |

| Test conditions: When the maximum circulation amount, the temperature difference between the temperature control temperature and the cooling water temperature is 15℃ |

|||||||

| Circulation pump | 7~20L/min 5bar | 15~40L/min 5bar | 20~60L/min 5bar | 40~110L/min 5bar | 150~250L/min 5bar | 250~500L/min 5bar | 400~650L/min 5bar |

| Tank volume | 5L | 10L | 20L | 30L | 60L | 120L | 240L |

| Dimension cm | 480*750*390 | 480*750*390 | 480*750*500 | Customization | Customization | Customization | Customization |

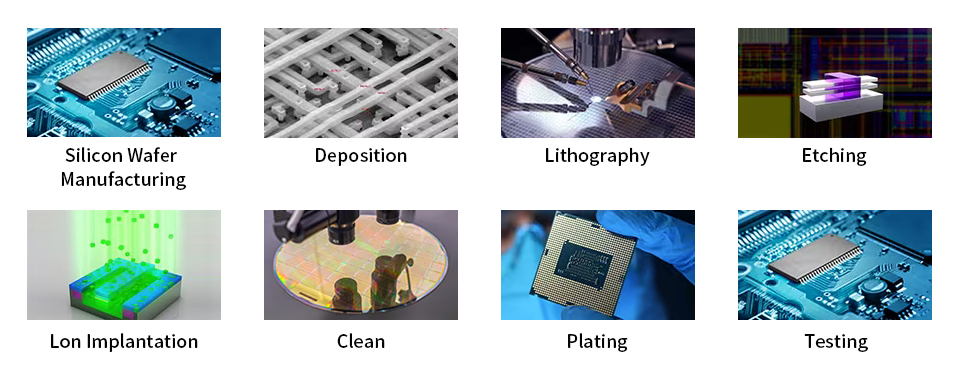

chillers that control the processing temperature on the Fab equipments

Single channel air-cooled cooler, mainly designed for etching machines. It is used to provide independent temperature control for the chamber side walls.

Applications

Submit your request to us and we will contact you within 24 hours

recommend products

FLTZ -45℃~90℃

Heating method within 40 ℃ adopts a compressor hot gas heating fully enclosed design, and the machine operates continuously for 24 hours The semiconductor temperature control device Chiller is mainly used for p…

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier