The entry point for the selection of industrial chillers

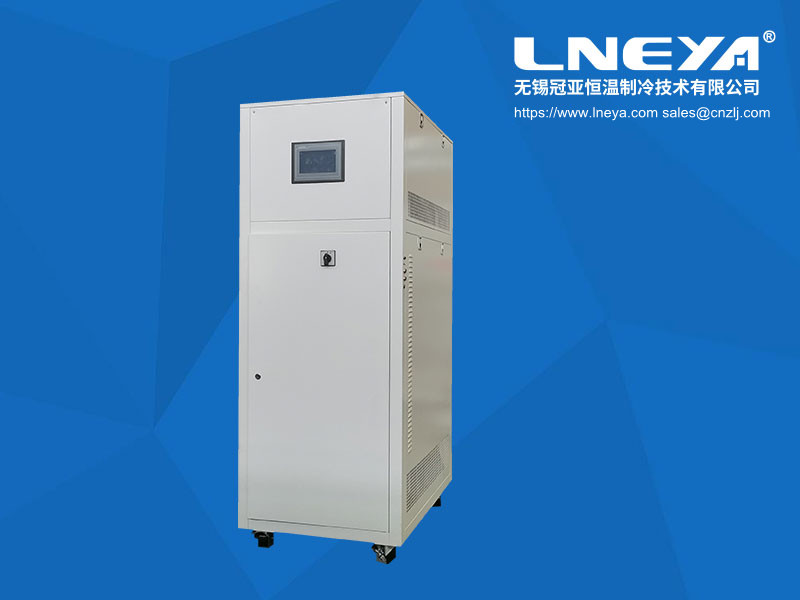

Industrial chillers are refrigeration devices that assemble refrigerators, condensers, evaporators, expansion valves, control systems, and switch boxes on a common base or frame. According to the heat rejection method of the unit, it can be divided into water-cooled and air-cooled chillers. The latter adopts heat pump circulation and is welcomed by users. After fully considering the above factors, what should we pay attention to when choosing a chiller?

The main configuration is:

Compressors, electrical components, water pumps, evaporators, condensers, high/low pressure controllers, high/low pressure gauges, LCD thermostats, expansion valves, antifreeze switches, hand valves, and fans. Screw chillers and high-precision constant temperature circulating chillers are trusted by well-known international and domestic vacuum instruments, analytical instruments, and other manufacturers.

Water circulatory system:

First inject a certain amount of water into the water tank of the chiller, cool the water through the chiller refrigeration system, and then send the low-temperature cooling water to the equipment that needs to be cooled by the water pump. The chilled water will take away the heat and increase the temperature before returning to The water tank achieves the cooling effect. The cooling water temperature can be automatically adjusted according to requirements, and long-term use can save water. Therefore, the chiller is a standard environmentally friendly and energy-saving equipment.

When choosing a chiller, you should also pay attention to the following points:

1. Generally, 2 to 4 refrigeration units are appropriate, 2 for small and medium-sized systems, 3 for larger ones, and 4 for extra-large ones. The possibility of mutual backup and switching between units should be considered. Combination schemes with different types and capacities of different units can be used in the same machine room to save energy consumption. At least one unit with a higher degree of automation, better regulation performance, and high efficiency operation under partial load should be selected among the units operating in parallel.

2. The refrigeration coefficient COP of the electric-driven refrigerator is higher than the thermal coefficient. However, each type of unit has its own characteristics and uses its strengths.

3. For the cold source of a large centralized system, it is advisable to choose a chiller with a compact structure, a small footprint, and a compressor, motor, condenser, evaporator, and automatic control components assembled on the same frame. For small systems, direct evaporative compression condensing units should be used.

4. Use domestically produced units as much as possible. my country’s refrigeration equipment industry has developed rapidly in the past ten years, and most of the product performance is close to the international advanced level, especially the small and medium-sized chillers, which are completely comparable to imported products, and have unparalleled advantages in price. Therefore, under the same conditions, domestic chillers should be selected first.

Related recommendations

-

Cooling fin cleaning instructions for 20 freezers

1236As one of the main accessories of the 20-piece freezer, the heat-dissipating fins are very important. Therefore, the cleaning of the heat-dissipating fins is also very important. How to clean them? The fins of the freezer are also called finned co...

View details -

-220 °C refrigerator installation instructions

1021The appearance and weight of different models of -220 °C refrigerator are different, so the installation is also important. -220 °C refrigerator should be placed indoors, should be placed in a solid and flat place, in order to reduce the vibration...

View details -

What should we pay attention to when purchasing cooling equipment for industrial chiller units?

863When many customers buy refrigeration equipment for industrial chiller units, they don't know what the key points are. Next, let me talk to you. 1. It should be determined according to the use, refrigerating capacity, local power supply, water sou...

View details -

Battery module test equipment selection error description

1064Many battery module companies have certain misunderstandings about LNEYA's battery module test equipment. There are some errors in selecting the battery module test equipment model, so try to select the battery module test equipment. Avoid some mi...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier