KRY -20℃~100℃ Low temperature chiller

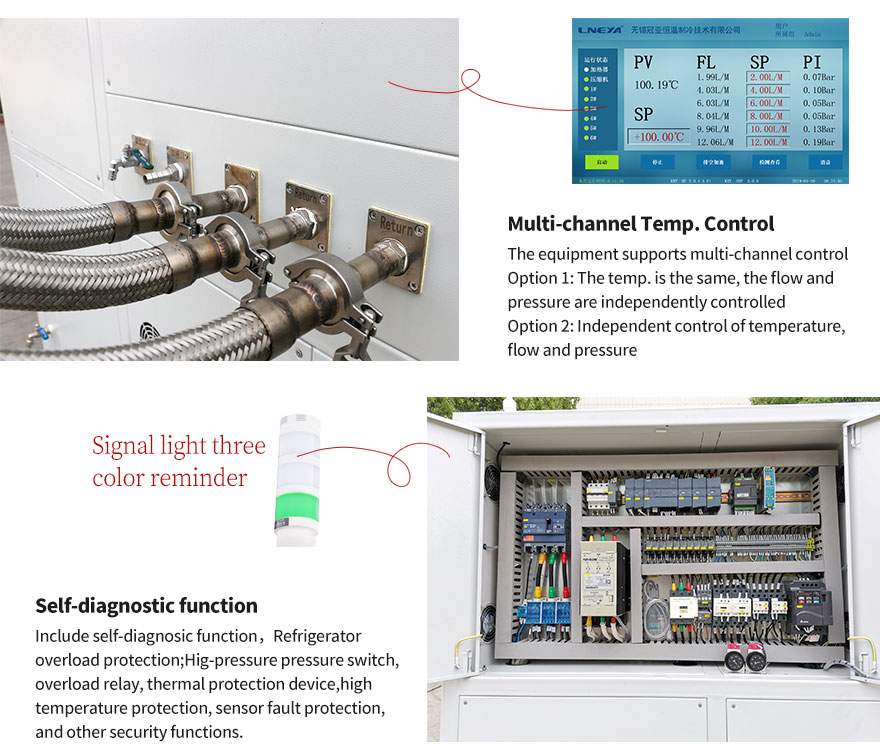

Control 6 test equipment at the same time, with consistent temperature and independent pressure/flow control- Heating Power15kW~38kW

- Cooling capacity10kW~60kW

- Power range36kW~75kW

- Temperature accuracy±0.5℃

- Flow accuracy/platform±0.2L

- RefrigerantR404A/R507C

- Weight900KG~1750KG

Product data download

Parameters

| Model | KRY-2A25W/6S | KRY-2A38W/6S | KRY-2A60W/6S | |

| Temp Range | -20℃~+100℃ | |||

| Temperature control precision | ±0.5℃ | ±0.5℃ | ±0.5℃ | |

| Temperature feedback | Pt100 | Pt100 | Pt100 | |

| Temperature display | 0.01k | 0.01k | 0.01k | |

| Flow control/Group | 1~20 L/min | 1~20 L/min | 1~40 L/min | |

| Flow control accuracy/Group | ±0.2L | ±0.2L | ±0.2L | |

| Number of fluid output groups | 6 groups | 6 groups | 6 groups | |

| Flow description | When the temperature control is lower than -30℃, the flow rate is controlled within 80% of the maximum value. | |||

| Flow pressure description | The unit can control the flow individually or separately. Need to control different solutions at the same time (customized) | |||

| Heating Power | 15KW | 25KW | 38KW | |

| cooling capacity | 100℃ | 25KW | 38KW | 60KW |

| 20℃ | 25KW | 38KW | 60KW | |

| 0℃ | 25KW | 38KW | 60KW | |

| -20℃ | 10KW | 15KW | 24KW | |

| Compression | Emerson Valley Wheel Compressor | |||

| Expansion valve/solenoid valve | Danfoss Thermal Expansion Valve / Emerson Solenoid Valve | |||

| Oil distributor | Emerson | |||

| Dry filter, Pressure control | Danfoss | |||

| Evaporator | Plate heat exchanger | |||

| Circulating pump | Magnetic drive pump | |||

| Frequency converter | Delta | |||

| Flow,Pressure sensor | Electromagnetic flowmeter, Johnson Controls pressure sensor | |||

| Input, Display | 5 inch color touch screen \ PLC controller | |||

| Communication | Modbus RTU protocol RS485 interface, optional CAN communication bus, Ethernet interface TCP/IP protocol | |||

| Safety protection | With self-diagnosis function; Refrigerator overload protection; High pressure switch, overload relay, thermal protection | |||

| system | absorb water in the air, the system in operation will not because of high temperature pressure rise, low temperature | |||

| automatically add heat conduction medium. | ||||

| refrigerant | R404A/R507C | |||

| Connection size | There are six groups of inlet and outlet,ZG3/4 | |||

| Cooling water@20C | 8000L/H | 12000L/H | 20000L/H | |

| Condenser(W) | Shenshi tube type heat exchanger | |||

| Condenser(A) | Optional air-cooled type, upper air outlet, the equipment size will be increased. | |||

| Power 380V50HZ | 36KW max | 51KW max | 75KW max | |

| Dimension cm | 200*145*205 | 200*145*205 | 200*145*205 | |

| Weight(W) | 900kg | 1100kg | 1750kg | |

| Optional | 220V 60HZ Three phase 400V 50HZ Three phase 440V 60HZ Three phase | |||

| Optional | Extend to -40~+135℃ | |||

| Optional | The size external circulation pipe line is DN15 or DN20, do not throttle, which will increase the circulation pump load, | |||

| pipe need to be insulated, and adopt rubber and plastic insulation pipe which can afford high temp. | ||||

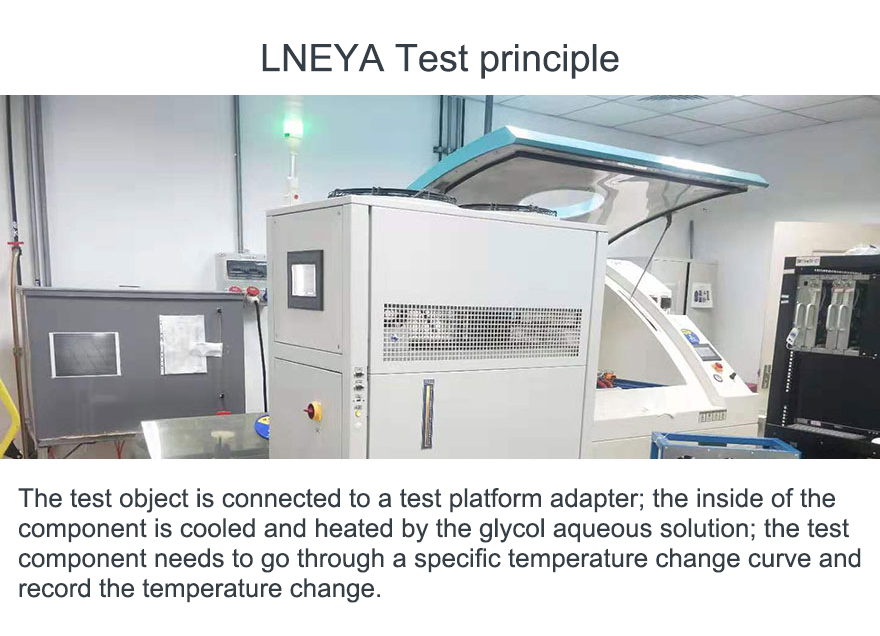

Product Description

The System Process Flow Is As Follows:

The liquid refrigerant in the evaporator of the unit is exchanged with the circulating air in the interior of the tank. The temperature rises from liquid to gas, and is sucked into the suction port of the compressor. The high-temperature and high-pressure refrigerant gas after compression by the compressor passes through The oil separator separates the refrigerating machine oil carried in the compression process, and then enters the condenser, and exchanges heat with ambient air or cooling water to change from high temperature and high pressure gas to high pressure normal temperature liquid. The high-pressure normal temperature refrigerant liquid is dried by a filter and then throttled and depressurized by an expansion valve, that is, from a high-pressure liquid to a low-pressure liquid. The low-pressure liquid (lower boiling point) enters the evaporator of the unit, and the cooling air is brought to the inside of the tank through the circulating air to achieve refrigeration.

The anti-freeze solution is injected into the 80L pressure vessel, and the fully closed circulation system is adopted. This avoids the opportunity for the antifreeze to contact with the outside air and ensures the condensation of the water. After the expansion tank is protected by nitrogen, the temperature range of the heat transfer liquid is also broadened because its boiling point is increased. In addition, oxidation of the thermally conductive liquid in contact with oxygen in the environment is also avoided, thereby extending the useful life of the thermally conductive liquid.

You may also be interested in these products

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier