Normal temperature chiller heater for Vehicle antifreeze test

KRY 0℃~100℃ 1&1- Heating Power2.5kW~38kW

- Cooling capacity1.8kW~60kW

- Power range4.5kW~61kW

- Temperature accuracy±0.5℃

- Flow rate output2~50 L/min

- RefrigerantR404A/R507C

- Weight220KG~1300KG

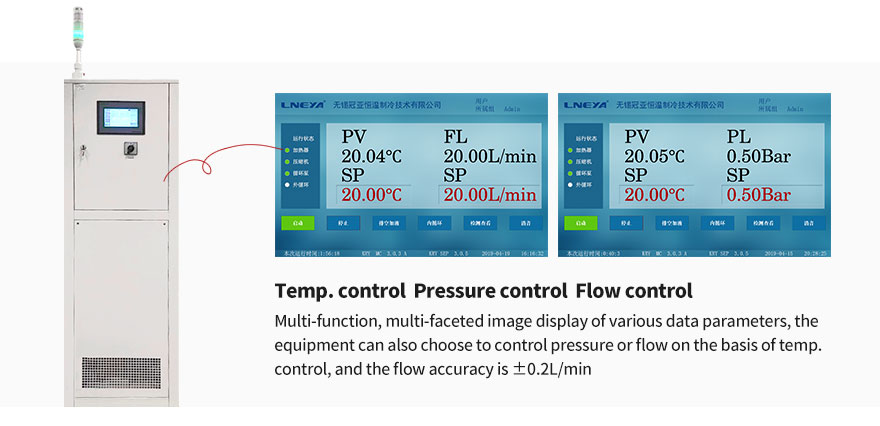

Temperature range is 0℃~+100℃, which can be extended to +135℃ according to the actual situation, and the temperature control accuracy is plus or minus 0.5℃. The equipment can control the flow and pressure independently while controlling the temperature, and different customized solutions are required for simultaneous control.

The tested object is attached to a test platform adapter.

The inside of the part was cooled and heated by an aqueous solution of ethylene glycol.

The test component needs to go through a specific temperature profile and record changes in temperature.

When performing a tolerance test, it usually takes an infinite loop

Equipped with a powerful circulation pump while ensuring the delivery of highly viscous liquids.

Control the flow output with variable frequency regulation or proportional control valve to achieve high precision control total range 5%~100% adjustment.

Parameters Detailed

| Model | KRY-25 | KRY-55 | KRY-75 | KRY-A10 | KRY-A15 | KRY-A25 | KRY-A38W | KRY-A60W | |

| KRY-A15W | KRY-A25W | ||||||||

| Temp. Range | 0℃~+100℃ | ||||||||

| Temp. control precision | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | |

| Temp. feedback | Pt100 | Pt100 | Pt100 | Pt100 | Pt100 | Pt100 | Pt100 | Pt100 | |

| Temp. display | 0.01k | 0.01k | 0.01k | 0.01k | 0.01k | 0.01k | 0.01k | 0.01k | |

| Flow rate output | 2~20 L/min | 2~25 L/min | 2~25 L/min | 2~25 L/min | 2~25 L/min | 2~25 L/min | 5~50 L/min | 5~50 L/min | |

| Flow rate accuracy | ±0.2 L/min | ±0.2 L/min | ±0.2 L/min | ±0.2 L/min | ±0.2 L/min | ±0.2 L/min | ±0.2 L/min | ±0.2 L/min | |

| Pressure display | Adopt the Jeffron pressure sensor, the touch screen display the pressure, can carry on the pressure control adjustment. | ||||||||

| Heating power | 2.5kW | 5.5kW | 7.5kW | 10kW | 10kW | 15kW | 25kW | 38kW | |

| Optional 15kW | Optional 25kW | Optional 38kW | Optional 60kW | ||||||

| cooling capacity | 100℃ | 2.5kW | 5.5kW | 7.5kW | 10kW | 15kW | 25kW | 38kW | 60kW |

| 20℃ | 2.5kW | 5.5kW | 7.5kW | 10kW | 15kW | 25kW | 38kW | 60kW | |

| 5℃ | 1.8kW | 3.8kW | 5.2kW | 7kW | 11kW | 18kW | 27kW | 42kW | |

| compression | HITACHI | Emerson Valley Wheel Compressor | |||||||

| expansion | Danfoss Thermal Expansion Valve/ Emerson Solenoid | ||||||||

| oil distributor | Emerson | ||||||||

| Dry filter, Pressure | Emerson/Danfoss | ||||||||

| Evaporator | Plate heat exchanger | ||||||||

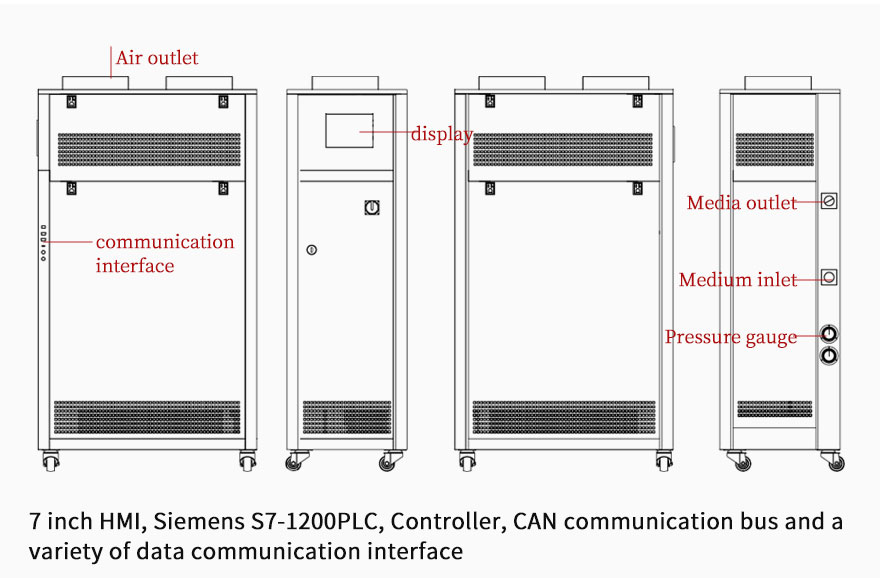

| input, Display | 7 inch color touch screen \ PLC controller | ||||||||

| program edit | 5 programs can be prepared, each program can be prepared 20 steps | ||||||||

| Communication | CAN communications bus | ||||||||

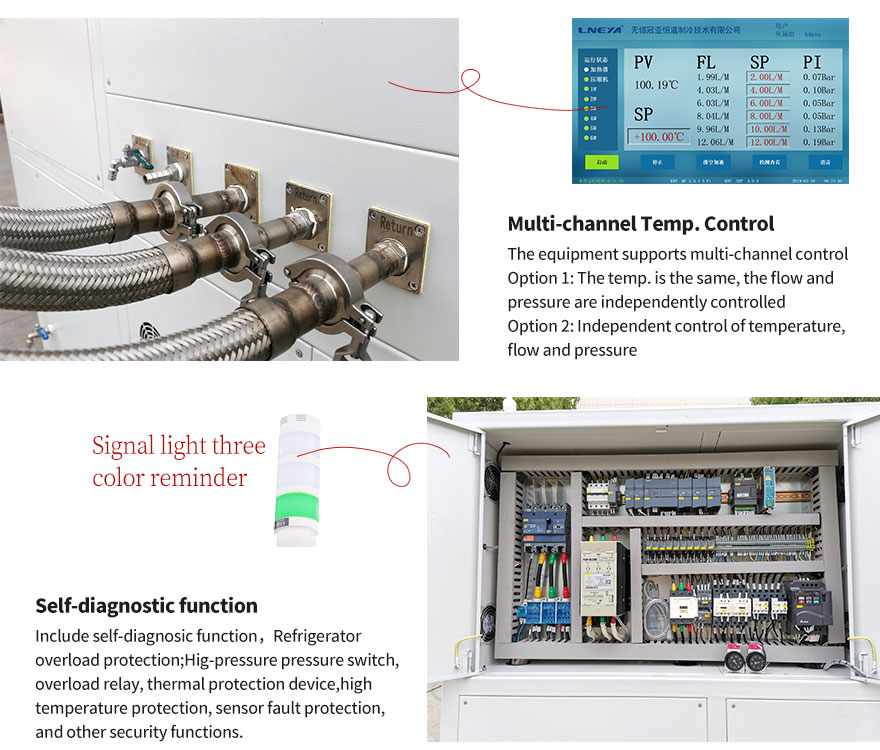

| Safety protection | With self-diagnosis function; Refrigerator overload protection; High pressure switch, overload relay, thermal protection | ||||||||

| device, low liquid level protection, high temperature protection, sensor fault protection and other safety functions | |||||||||

| is it a fully closed system | The whole system is a fully closed system, there will be no oil mist at high temperature, and the water in the air will not be absorbed at low temperature. The system will not increase the pressure due to high temperature in operation, and the thermal conduction medium will be automatically supplemented at low temperature. | ||||||||

| refrigerant | R404A/ R507C export adopt R448A | ||||||||

| Flow sensor | German brand flowmeter | ||||||||

| Connection size | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | |

| Cooling water at 20C° | 3200L/H | 6000L/H | 9000L/H | 15000L/H | |||||

| Condenser(W) | Tube type heat exchanger (Paris/Shenshi) | ||||||||

| Condenser(A) | Copper tube aluminum finned heat exchanger (upward wind) | ||||||||

| Power 380V50HZ | 4.5kW220V | 8.5kW | 11.5kW | 16kW | 18kW | 28kW | 40kW | 61kW | |

| Dimension cm | 40*70*160 | 55*100*175 | 55*100*175 | 70*100*175 | 80*120*185 | 100*150*185 | 100*150*185 | 100*150*185 | |

| Weight | 250kg | 280kg | 320kg | 360kg | 620kg | 890kg | 1300KG | ||

| Optional | 220V 60HZ three phase 460V 60HZ three phase | ||||||||

| Optional | Higher precision control of temperature, flow and pressure | ||||||||

| Optional | Automatic antifreeze filling system | ||||||||

| Optional | Automatic liquid recovery system | ||||||||

Product Description

Working Principle

Temperature simulation for vehicle quality test: battery life test, fuel injector/motor test bench, airbag test, component test bench, etc. It can simulate the external environmental conditions in the climate chamber or replace the internal system, which can create the necessary actual temperature conditions for the test bench.

You may also be interested in these products

KRY -40℃~+100℃ (1to6)

The components are cooled and heated internally through ethylene glycol aqueous solution for testing -40 ° C~100 ° C (expandable to 150 ° C) For the power battery charging management, the precision …

KRY -40℃~+100℃ (1to1)

Refrigeration, heating, temperature control, flow control Connect the tested object to a testing platform adapterThe components are cooled and heated internally through ethylene glycol aqueous solution for testing. …

KRY -40℃~+100℃ (1to2)

Temperature range is -40℃~+100℃, which can be extended to +135℃ according to the actual situation, and the temperature control accuracy is plus or minus 0.5℃. Theequipment can control the flow and pressure independently while c…

KRY -40℃~+100℃ (1to3)

Dimension(A) cm Temperature range is -40℃~+100℃, which can be extended to +135℃ according to the actual situation, and the temperature control accuracy is plus or minus 0.5℃. Theequipment can control the flow and…

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier