Data center Liquid Cooling Chiller

For Servers Cooling/Rack Cooling

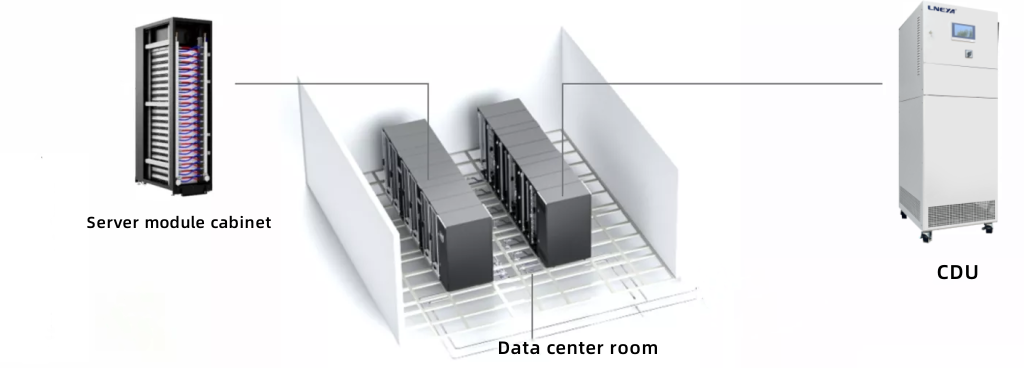

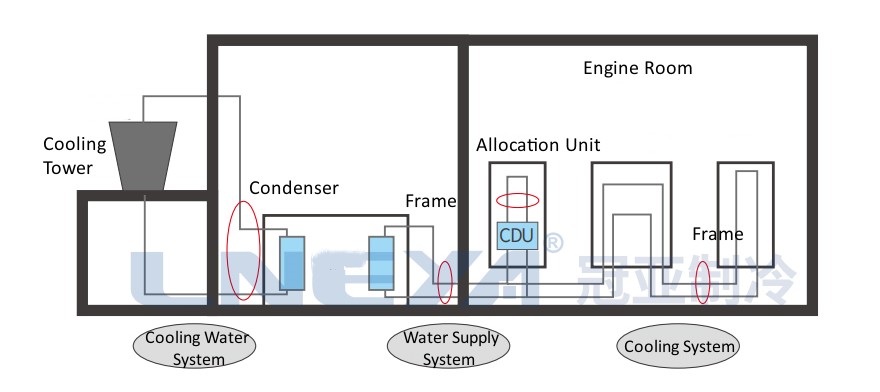

CDU will become the mainstream thermal solution in the data center. In general, cooling systems with radiators, fans, air conditioning units, etc. are considered insufficient for CPUs over 300W. To continue normal operation of the 300-1000W high-power CPU and improve computing and processing efficiency, it is necessary to properly handle the heat through the CDU.

High cooling performance is not the only advantage of the CDU: Compared with air-cooled units, its major advantage is that it consumes less power and has less loss of liquid cooling media.

Reduce the energy consumption of refrigeration systems

Use liquid cooling plate heat exchange to cool the main heat source inside the server and reduce the use of air cooling systems.

Liquid-cooled CDU provides coolant circulation for cold plates that are in direct contact with server heating components.

The coolant distribution unit of our LNEYA can be said to be a liquid-to-liquid type, which greatly reduces the ratio of high loss of coolant in the past, and has high safety and reliability.

ALL TYPE

Cold Plate Liquid Cooling

Air-liquid structure

heat dissipation up to 15KW

Cabinet Liquid Cooling

Liquid cooling cycle

heat dissipation up to 300KW

ZLFQ series Temperature accuracy ±0.2℃

Cold Plate Liquid Cooling CDU-15kW

|

Model

|

ZLFQ-15

|

ZLFQ-25

|

ZLFQ-50

|

ZLFQ-75

|

ZLFQ-100

|

ZLFQ-150

|

|||||

|

Temp Range

|

Cooling Water Temperature+5℃~35℃

|

||||||||||

|

Cooling Water

|

5℃~30℃ Adopt Siemens/Honeywell regulating valve to control cooling water flow

|

||||||||||

|

Temp Control Accuracy

|

±0.2℃

|

±0.5℃

|

|||||||||

|

Flow Control

|

10~25L/min

|

25~50L/min

|

40~110L/min

|

70~150L/min

|

150~250L/min

|

200~400L/min

|

|||||

|

|

The flow control is adjusted by frequency converter, the precision ±0.3L/min

|

||||||||||

|

Cooling Capacity(MAX)

|

15kW

|

25kW

|

50kW

|

75kW

|

100kW

|

150kW

|

|||||

|

Storage Volume

|

15L

|

30L

|

60L

|

100L

|

150L

|

200L

|

|||||

|

Brine

|

Water, silicone oil, fluorinated liquid, ethylene glycol aqueous solution, etc.

|

||||||||||

|

Controller

|

PLC, fuzzy PID control algorithm, with cascade control algorithm

|

||||||||||

|

Temp Control

|

Heat transfer medium outlet temperature control mode, with cascade control algorithm

|

||||||||||

|

Letter of agreement

|

Ethernet interface TCP/IP protocol

RS485 interface modbus RTU protocol |

||||||||||

|

Device Internal Temperature Feedback

|

Equipment heat transfer medium outlet temperature, medium inlet temperature, cooling water temperature

|

||||||||||

|

Tank Level

|

Import and export pressure sensor detection, cooling water pressure detection

|

||||||||||

|

Medium Pipeline

|

SUS304

|

||||||||||

|

Heat Exchanger

|

Plate heat exchanger, special attention: need to use clean factory water

|

||||||||||

|

Operation Panel

|

LNEYA customized 7-inch color touch screen, temperature curve display\EXCEL data export

|

||||||||||

|

Security

|

With self-diagnosis function; phase sequence and phase failure protector; pressure protection, overload relay, thermal protection device and other safety protection functions.

|

||||||||||

|

In and out interface size

|

ZG3/4

|

ZG1

|

ZG1

|

DN32

|

DN40

|

DN50

|

|||||

|

Cooling water interface

|

ZG3/4

|

ZG1

|

DN40

|

DN50

|

DN50

|

DN65

|

|||||

|

Cooling Method

|

Water-cooled, the factory water temperature is lower than the minimum temperature provided by the equipment by more than 3°C, and the water temperature fluctuation is ≤3°C

|

||||||||||

|

Cooling Water Flow 7~20℃

|

2.5m³/h

|

4m³/h

|

8m³/h

|

13m³/h

|

17m³/h

|

25m³/h

|

|||||

|

Power 380V 50HZ

|

1kW

|

1.5kW

|

3kW

|

4kW

|

5kW

|

6kW

|

|||||

|

Shell Material

|

Cold-rolled

|

||||||||||

ZLFQ series Temperature accuracy ±0.5℃

Cabinet-type liquid cooling CDU-300kW

|

Model

|

ZLFQ-200

|

ZLFQ-250

|

ZLFQ-300

|

ZLFQ-400

|

ZLFQ-500

|

|

Temp Range

|

Cooling Water Temperature+5℃~35℃

|

||||

|

Temp Control Accuracy

|

±0.5℃

|

||||

|

Flow Control

|

15~30m³/h

|

20~35m³/h

|

25~40m³/h

|

30~60m³/h

|

40~70m³/h

|

|

|

Flow control is adjusted by frequency converter

|

||||

|

Cooling Capacity(MAX)

|

200kW

|

250kW

|

300kW

|

400kW

|

500kW

|

|

Storage Volume

|

250L

|

300L

|

600L

|

1000L

|

1200L

|

|

Cooling Method

|

Heat exchange between factory service water and brine, and brine provides cooling capacity for heating equipment

|

||||

|

Brine

|

Water, silicone oil, fluorinated liquid, ethylene glycol aqueous solution, etc.

|

||||

|

Controller

|

PLC, fuzzy PID control algorithm, with cascade control algorithm

|

||||

|

Temp Control

|

Heat transfer medium outlet temperature control mode

|

||||

|

Letter of agreement

|

Ethernet interface TCP/IP protocol

RS485 interface modbus RTU protocol |

||||

|

Device Internal Temperature Feedback

|

Equipment heat transfer medium outlet temperature, medium inlet temperature, cooling water temperature

|

||||

|

Tank Level

|

Pressure sensor real-time monitoring

|

||||

|

Medium Pipeline

|

SUS304

|

||||

|

System Pressure

|

Using the pressure sensor to detect and display on the touch screen

|

||||

|

Heat Exchanger

|

Plate heat exchanger, special attention: need to use clean factory water

|

||||

|

Operation Panel

|

LNEYA customized 7-inch color touch screen, temperature curve display\EXCEL data export

|

||||

|

Security

|

With self-diagnosis function; phase sequence and phase failure protector; pressure protection, overload relay, thermal protection device and other safety protection functions.

|

||||

|

In and out interface size

|

DN65

|

DN65

|

DN65

|

DN80

|

DN80

|

|

Cooling water interface

|

DN80

|

DN80

|

DN100

|

DN100

|

DN125

|

|

Cooling Method

|

Water-cooled, the factory water temperature is lower than the minimum temperature provided by the equipment by more than 3°C, and the water temperature fluctuation is ≤3°C

|

||||

Are You Looking For Dater Center liquid Cooling Unit?

Which type meets your work situation?

Working principle

Indirect contact liquid cooling system: heat is exchanged with the coolant inside the server in the heat exchanger outside the server through an intermediary fluid (such as fluorinated liquid), and then the intermediary fluid is transferred to the external cooling system.

Cooling water enters the unit and exchanges heat with the thermal conductivity medium, taking away the heat of the thermal conductivity medium and reaching the predetermined temperature for use. It can automatically adjust frequency conversion according to system pressure, temperature, and flow rate.

Using liquid cooling heat exchange to cool the main heat source and reduce the use of air-cooled systems. By using liquid cooling equipment to provide cooling liquid circulation for heating elements, the air heat exchange process is saved, and a large amount of energy consumption in refrigeration systems is saved.

Equipment appearance

- Fengliu structure

- Heat dissipation up to 12kW

- PUE≤1.2

- Plug-in frame design

- Hot and cold aisle isolation

- The heat dissipation is as high as 15kW, which can quickly complete the construction of edge computer rooms and the transformation of old computer rooms. Annual OUE≤1.2, heat exchange increased by 10%.

Mainly Used For:

5G Base Station

Internet Data Center

Power Industry

Supercomputing Center

Financial Data Center

Game Rendering Industrial

Research Institutions

Medical Industry

Seller location

Our distributors and customers are located in Southeast Asia, including Japan, South Korea, Singapore, Malaysia, Thailand, Indonesia, Vietnam, the United States, Britain, France, Germany, Italy, Czech Republic, Netherlands, Colombia, India, Russia, and other countries. If you need a quotation and solution, please send us a message through the following methods.

Provide 7 * 24 Scan the QR code for consultation

Email: market@lneya.com

WeChat 18914253067

WhatsApp: +86-18914253067

Related recommendations

-

Rotary Evaporator 1-50L

2254Small desktop rotary Evaporator 1L~5L Pilot and ground mounted rotary evaporators 10L~50L Rotary evaporator, also known as rotary evaporator. It consists of motor, distillation flask, heating pot, condenser and other parts. It is...

View details -

Molecular distillation (Short range distillation)

2474Short range distillation (molecular distillation) is a new separation technology that can solve problems that conventional distillation techniques cannot solve. It can achieve liquid-liquid separation at temperatures far below the boilin...

View details -

Laminated Glass Reactor

2303Double-layer glass reactors are suitable for the reaction of large amounts of liquids. The heating speed is fast and uniform, but the operation is more complicated and requires strict control of temperature and pressure. The interlayer c...

View details -

AET Series

4566Suitable for IC testing of all kinds of semiconductor chips,flash memory Flash/EMMC, PCB circuit boards, opticalcommunications,electronic industries, etc. Rated test conditions: dry bulb temperature 20℃; wet...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier