News

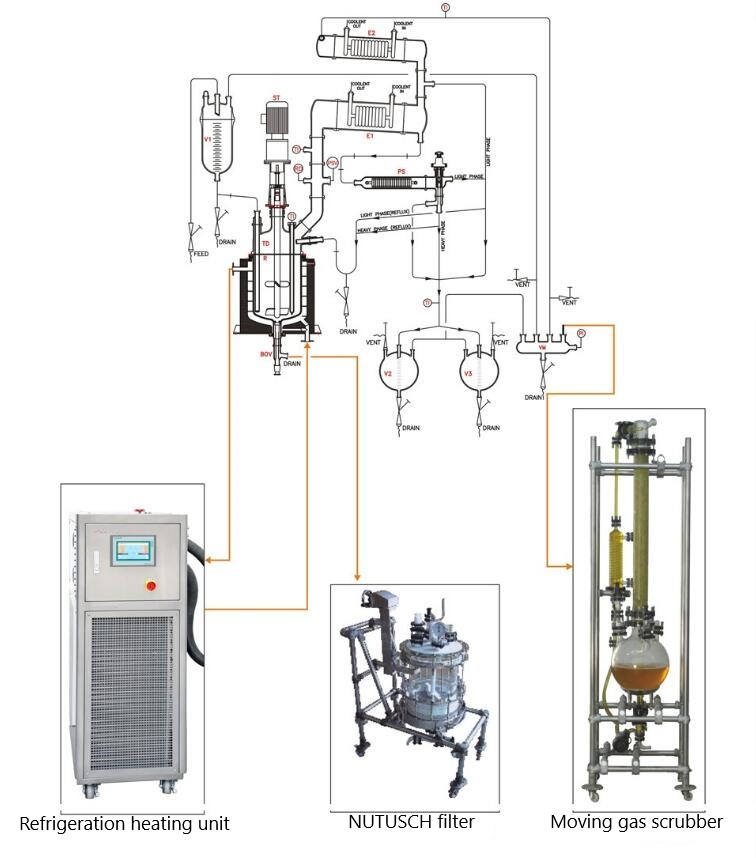

Description of pump selection in steam-saturated system temperature control unit

The steaming system temperature control unit is one of the more used equipment in the pharmaceutical chemical industry. The performance of the LNEYA steaming system temperature control unit depends on the design of the whole system and the specific performance of the accessories. The pump is used as a temperature control unit in the steaming system. A small accessory, its performance can not be ignored, then, how to choose the pump in the steaming system temperature control unit? The pump of ...

View details

How to choose a cooling bath and maintenance points

The so-called refrigeration thermostat, as its name suggests, is a device that provides a constant temperature. In general, everyone also calls it an incubator, a thermostat, and so on. Only know enough to use the cooling bath better. Refrigeration thermostats are widely used in petrochemical, chemical and pharmaceutical, bioengineering, life sciences, light industrial foods, sample testing and other industries to provide a high-precision constant temperature liquid environment for constant t...

View details

How to solve the problem of refrigeration pump circulator pump failure?

Cooling heating devices are required in many chemical pharmaceutical and laboratory applications. Then how to solve the failure of the refrigeration heating device is also concerned about how to solve it? 1. Circulating pump failure The circulating pump fault is generally the thermal overload of the circulating pump. There are four main reasons for this fault: The first is that the outer circulating pipeline of the heat conducting oil is too long. At this time, it is necessary to shorten the ...

View details

TCU temperature control model selection and technical parameter description

TCU temperature control is also a two-cycle unit single-fluid temperature control system. When selecting the model, it is very important for the whole temperature control reaction. Only the appropriate reaction system is used to exotherm and absorb the whole reaction process. The heat responds to the entire control, so the choice of model is very important. TCU temperature control model: SR-10 Model SR-10 with operating temperature range of -120~200°C, suitable reaction vessel is 50L-250L, ci...

View details

What are the places to choose for the chilled?

Today, with the development of science and technology, many customers focus on using high and low temperature to improve the quality of products and reduce the cost of products. So what are the places to pay attention to when choosing a model? Many customers ask for cooling when they use cooling water, which is generally used to dissipate heat. This method has been common for some time, but it has certain defects and cannot achieve a high-precision control. The purpose of temperature is that ...

View details

Analytical description of accessories used in low temperature chiller

The low temperature chiller still uses a larger amount of cooling water equipment in our usual refrigeration equipment. When using it, you must first understand the principle of the low-temperature chiller and various accessories to better operate the low-temperature chiller. The low temperature chiller is a water-cooled cooling device that can provide a certain constant temperature, constant current and constant pressure refrigeration equipment. It uses the water tank in the machine to injec...

View details

Low temperature chilled lubricant selection considerations

When you use a cryogenic chilled, you definitely want to know about all aspects of the cryocooler. But one of the things that needs everyone's attention is that the type of lubricant for the chilled is chosen because there are many influencing factors. When you choose, you need to choose carefully. There are many types of compressors for cryogenic chilled. Generally, pistons, screws, and centrifugals are commonly used. Among them, the piston type and screw type compressor are in direct contac...

View details

Matters Needing Attention in Maintenance of Low Temperature Chamber

2.The temperature and humidity of the low temperature chamber are the important factors affecting the performance of the instrument. It can cause the corrosion of mechanical parts, reduce the smoothness of metal mirror, and cause the error or performance degradation of mechanical parts of high and low temperature test box. The corrosion of optical components such as gratings, mirrors and focusing mirrors in high and low temperature test boxes results in insufficient light energy, stray light,...

View details

Specific operation analysis How to dehumidify when using industrial freezer

In the process of using industrial freezers, there may be some moisture in the refrigeration system. Therefore, the dehumidification of industrial freezers is very important, so how to dehumidify? When dehumidifying, users who purchase industrial freezers need to be aware that not all freezers contain moisture. LNEYA industrial freezers use fully enclosed circulation lines, which you can rest assured when using them. There will be no water and fog when running! So, how do you dehumidify a ful...

View details

How is a low temperature chiller suitable for the mold industry?

Everyone knows that the use of low temperature chillers is relatively extensive, especially in the mold industry. When the low temperature chiller is used to cool the mold, the mold is generally cooled together with the injection molding machine. Generally speaking, the mold is equivalent to a heat exchanger, and the heat is transferred from the mold to the mold and then from the mold to the cooling medium for cooling. Everyone knows that mold molding is inseparable from the function of cooli...

View details LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier