How to solve the problem of refrigeration pump circulator pump failure?

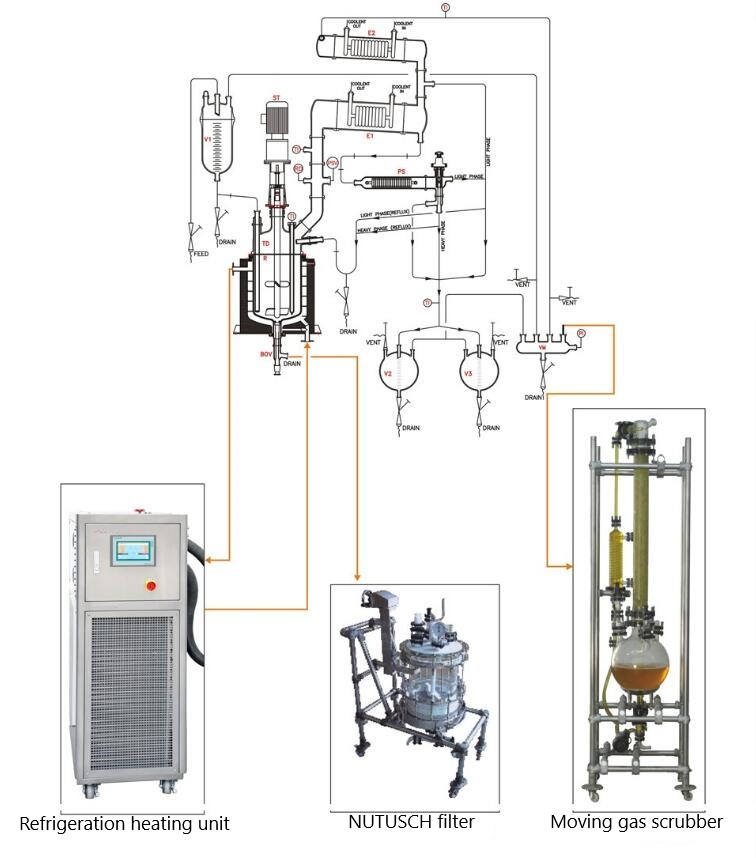

Cooling heating devices are required in many chemical pharmaceutical and laboratory applications. Then how to solve the failure of the refrigeration heating device is also concerned about how to solve it?

1. Circulating pump failure

The circulating pump fault is generally the thermal overload of the circulating pump. There are four main reasons for this fault: The first is that the outer circulating pipeline of the heat conducting oil is too long. At this time, it is necessary to shorten the outer circulation pipeline, reduce the bending of the outer circulation pipeline, and then click Equipment electrical cabinet surface thermal relay Reset button; the second is the circulation pipeline blockage, cooling and heating device which is good to tell everyone, check the circulation pipeline cleaning, install the filter, and then click the equipment electrical cabinet surface thermal relay Reset button; The third is that the circulating pump voltage is too low. It is recommended to measure whether the circulating pump voltage meets the specified range, improve the voltage environment, click the Reset button of the equipment electrical cabinet surface thermal relay; the fourth is that the thermal relay regulates the current too small. At this time, it is recommended to measure the pump current. Compare the range of thermal relays, Phillips screwdriver to properly rotate the thermal relay current, click on the equipment electrical cabinet surface thermal relay Reset button.

2. Sensor failure

A great possibility of sensor failure is wiring error. Once the fault is encountered, check the wiring situation. At this time, you should pay attention to two situations, one is sensor short circuit or temperature <-160 °C, and the other is sensor open circuit or temperature > 349 ° C.

If the sensor is short-circuited or the temperature is <-160 °C, it may be the fault of the sensor itself. At this time, it is recommended to replace the sensor (there is a spare sensor in the equipment slot). If the sensor is wired incorrectly, It is recommended to check the wiring (corrected circuit diagram) correction.

If the sensor is open circuit or the temperature is >349°C, it should be the fault of the sensor itself. It is necessary to replace the sensor in time (there is a spare sensor in the equipment slot). At this time, it is necessary to pay attention to whether the temperature is too high and the temperature is too high. Check whether the temperature is exceeded. Range, if the equipment is not powered, pay attention to check the power supply of the equipment.

These two faults of the cooling heating device are still relatively simple. I believe that everyone who has seen the sharing can solve it very quickly.

Related recommendations

-

Is the low temperature cooling unit – 120 degrees cooling effect reliable?

1845LNEYA specializes in the production of single-fluid cryogenic cooling units, the cooling temperature range is from -150 degrees to -5 degrees, which can meet different cooling temperature requirements. The products are widely used in low temperatu...

View details -

What are the conditions for the decarboxylation reaction? How to control the temperature of heating?

1836The decarboxylation of aromatic acids is easier than that of fatty acids. For example, benzoic acid can be decarboxylated by adding a little copper powder as a catalyst in quinoline solution and heating. When a strong electron-withdrawing group i...

View details -

Accurate temperature control for battery testing to improve the performance of electric vehicles

1270Electric vehicles (EVs) have completely transformed the automotive industry, providing a more sustainable and energy-efficient mode of transportation. One of the basic components of electric vehicles is their rechargeable battery. Electric v...

View details -

The role of temperature control system TCU in chemical and pharmaceutical reactor

1994The temperature control of the reaction kettle in drug research and development and chemical experiments, as well as the temperature control in small-scale experimental production and industrial production processes, require highly dynamic tempera...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier