What are the main hazards of the reaction kettle in the reactor intelligent temperature control syst

The intelligent temperature control system of the reactor is used in various chemical fines. With the constant attention of the industry safety issues, some risk factors of the intelligent temperature control system of the reactor should be avoided in time.

In the pharmaceutical and chemical industry, it operates in various fine productions. In the chemical industry, there are many intelligent control systems for reactors, many storage tanks, and a wide network of pipe networks. From a structural point of view, the entire production system is composed of several production units. Reactor intelligent temperature control system Each production unit is composed of one or more reactors, a condenser and a rectification tower.

The material in the kettle is too fast, the cooling rate is low, and the condensation effect is poor, which may cause the material to boil, form a vapor-liquid mixture, generate pressure, weak links from the venting tube, vapor phase tube, safety valve, and blasting. The pressure relief system such as the sheet is subjected to pressure relief and compaction. If the material cannot reach the submerged fruit with rapid pressure relief, it may cause the explosion of the kettle body.

If the welding and gas cutting maintenance work is carried out without taking effective precautions during the material reaction process in the intelligent temperature control system of the reaction kettle, or the bolts and irons are hit and beat to generate sparks, once the inflammable and explosive materials are encountered May cause fire and explosion.

It should be noted that the feed temperature of the reactor intelligent temperature control system is too fast, the feed ratio is out of control, or the feed sequence is wrong. It is possible to generate a rapid exothermic reaction. If the cooling cannot be synchronized, heat accumulation will occur, causing the material to be partially decomposed by heat. The material reacts quickly and generates a large number of hazardous gas accidents.

In the operation of the intelligent temperature control system of the reaction kettle, when feeding, for the atmospheric pressure reaction, if the venting tube is not opened, when the liquid material is transported into the kettle by the pump at this time, the positive pressure is easily formed in the kettle, which may cause the connection of the material pipe. Cracking, material accidents cause burns caused by personal injury. When unloading, if the material in the kettle is unloaded when it is not cooled to the specified temperature, the material at higher temperature is easily deteriorated and it is easy to cause the material to splash and burn the operator.

We need to pay attention to the issue of production safety, and do a good job in safety in time to avoid personal injury caused by improper use.

Related recommendations

-

Vapor deposition coating machine temperature control system-cooling water system

1698The main purpose of the vapor deposition coating machine is to carry out scientific experiments and research on film formation process. It is composed of quartz tube reaction chamber, heat shield furnace cabinet, electrical control system, vacuum ...

View details -

-80 °C refrigerator manufacturer operating equipment points

1484When the user chooses the -80 °C refrigerator, it is definitely necessary to have a reliable quality. Wuxi Guanya (LNEYA)-80 °C refrigerator should pay attention to its operation details during operation to avoid equipment failure caused by improp...

View details -

Low temperature circulating chiller startup and shutdown operation

1671When the low temperature circulating chiller is turned on, it can be automatically turned on when the manual start is selected. The automatic start-up needs to open the compressor exhaust shut-off valve, start the cooling water pump and the coolan...

View details -

Ultra Low Temp Chiller Features

1616The ultra low temp chiller is controlled by microcomputer, and the refrigeration compressor and its system components are energy-saving products, which greatly improves the reliability of the whole machine. The unit can realize multi-stage energy ...

View details

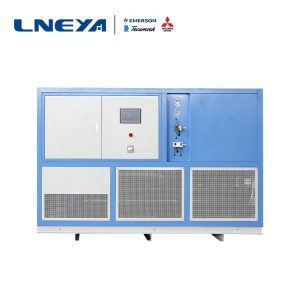

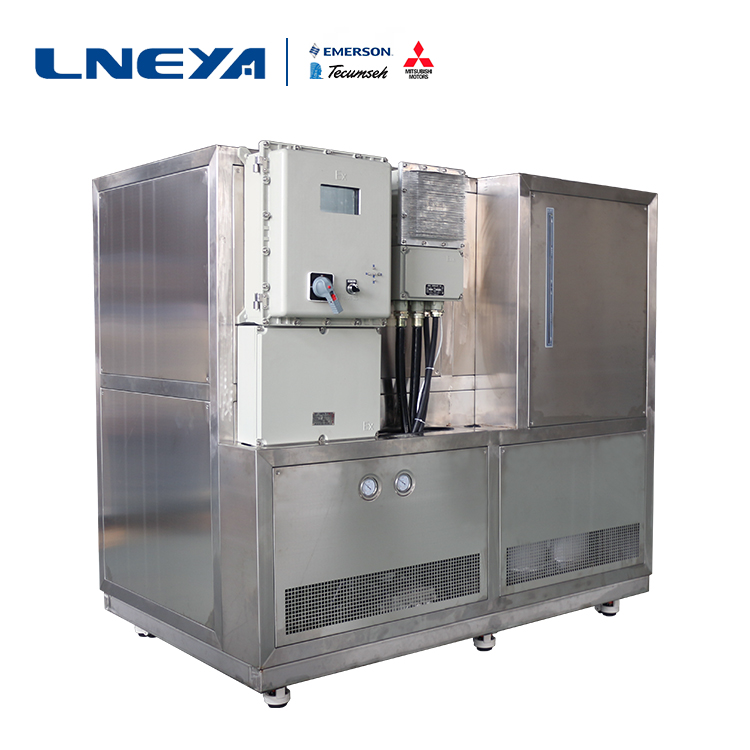

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier