The cooling circulation system is used to collect the non-condensable tail gas in the distillation s

Most rectification towers are two-stage condensation. The first stage uses cooling water, mainly condensing the top steam, and the second stage uses chilled water or ethylene glycol, which is mainly used to treat tail gas and remove a small amount of light components. The exhaust gas is condensed. Therefore, the secondary condensation is very small.

Generally, a rectification tower (especially in the case of non-condensable gas, such as a vacuum tower, an atmospheric tower with gas dissolved in the feed, etc.), a two-stage condenser is placed on the top of the tower, and the first stage is cooled by cooling water. Part of the top steam is condensed, and the second stage adopts chilled water cooling to condense the light components in the tail gas as much as possible to reduce material loss. The reason for this is that the operating cost of chilled water is much greater than that of circulating chilled water, so it can be used as little as possible. The primary cooler uses cooling water to condense most of the easily condensable media, and the secondary cooler uses chilled water to condense the remaining small part of the exhaust gas that is not easy to condense. This can reduce the use of chilled water and save energy.

Distillation device, the device is divided into two stages of distillation, the first stage distillation condenser uses cooling water for condensation, while the second stage uses chilled water for condensation. The first stage adopts cooling water cooling to condense most of the top steam, and the second stage adopts chilled water cooling to recover the light components in the tail gas as much as possible to reduce material loss. The light components of the two stages are the same, but the amount of steam from the top of the second stage is smaller than that of the first stage. What is the difference between using chilled water to condense and chilled water to condense? Why do the primary and secondary condensers use different cold media for condensation?

Cooling water is circulating water, the temperature is generally 32-40 degrees. Low cost, easy to use, economical. Chilled water is low-temperature water produced by a low-temperature system. The temperature is generally below 20 degrees, and there are many grades to choose from. Chilled brine is relatively expensive, so the primary cooling will condense a lot of steam, and the secondary will condense the remaining steam.

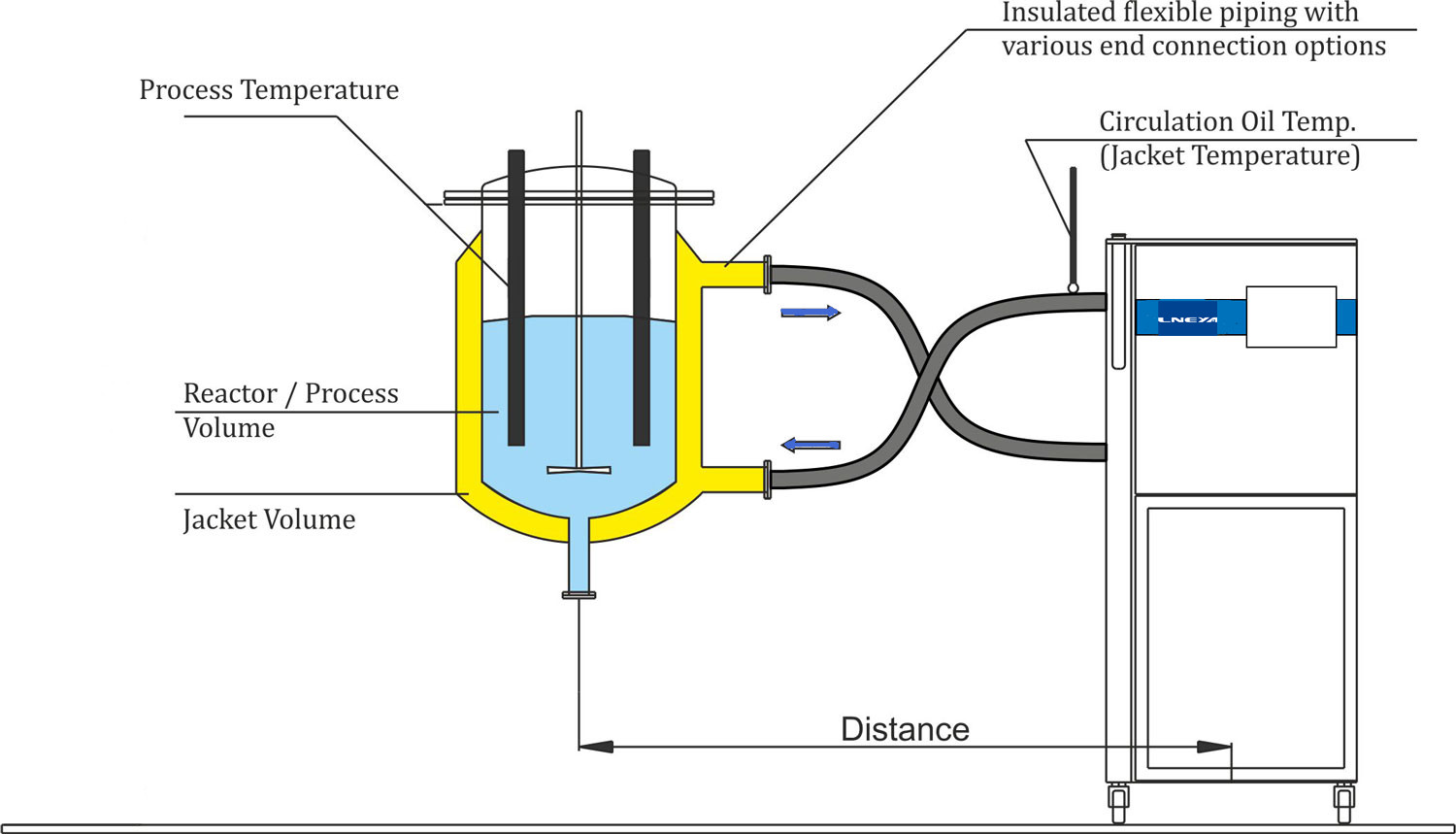

For the recovery of non-condensable tail gas components in the distillation system, cooling water and chilled water are indispensable, but this also invisibly increases the consumption of resources. The role of one or more water cooling systems is particularly important. The LNEYA cooling cycle system adopts secondary subcooling, which has a fast cooling speed, safe and reliable, and is used for rapid liquid cooling. It is widely used in petrochemical, medical, pharmaceutical, biochemical, freeze-drying, pharmaceutical, military and other high-tech industries. In order to save water resources, ethylene glycol-water mixture can be used for circulating refrigeration, and the circulation pipeline design is strictly designed to prevent circulating water pollution and extend the use time of circulating water.

Related recommendations

-

You Should Know Something About Ultra Low Temperature Freezer

1248Ultra low temperature freezer is an indispensable cryogenic storage equipment in the field of life sciences and biopharmaceuticals. It can be used to store cells, tissues, test samples, vaccines, active enzymes, strains, plasmids, viruses, bacteri...

View details -

Why does a chiller need to be installed for cooling the water storage tank?

1507The main reasons for configuring a chiller for cooling the water storage tank are related to the following aspects: Temperature Control: In many industrial and commercial applications, such as air conditioning systems, chemical processes, ...

View details -

Temperature control range and accuracy of high and low temperature tester

1564The temperature control accuracy of heat transfer oil medium of the high and low temperature tester used for component testing is plus or minus 0.5 ℃, which solves the problem of temperature control lag in electronic components. Main advantages of...

View details -

Selection of ultra-low temperature chiller supporting the glass reactor

1487In order to achieve an economical ultra-low temperature environment for glass reactors, many customers will not choose multi-stage compressor refrigeration equipment with more than two stages, but use liquid nitrogen. The cost of liquid nitrogen...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier