Is the temperature control equipment for semiconductor component testing a chiller?

Semiconductor component testing temperature control equipment is used in the simulation test of the temperature performance of semiconductors, chips and other components, and conducts temperature tests in different temperature ranges within the range of -85~200℃.

One, equipment background

In the component industry, the requirements for various semiconductors and chips are relatively high. It is particularly necessary to test the performance status of components in different environments, as well as different temperature tests and other performance tests under packaging and assembly production, so as to avoid components such as components. After entering production, the electronic products are actually put on the market and face a variety of unusual environments that cause the electronic components to be unusable.

Second, role

Semiconductor component testing temperature control equipment performs high and low temperature cycle testing, high and low temperature temperature impact testing, failure analysis and other reliability tests on components, integrated circuits, modules, PCBs, assembly and other applications. In addition to semiconductor component testing temperature control equipment, industry professionals can also call them heat flow meters, hot and cold air impact machines, temperature forced systems, high and low temperature air circulation systems, and semiconductor testing chiller.

Related recommendations

-

The Difinition and Application of Heating Cooling Circulator

1431Before discussing how to choose the right brand of heating cooling circulator, we need to know the definition and application of heating and cooling circulator. Definition: thermostatic waterbath is also called the thermostatic water tank, constan...

View details -

How to choose low temperature and high temperature simulation equipment for material aging test?

1723Material aging testing is used in many industries, but how to choose high-quality low-temperature and high-temperature simulation equipment is very critical, because temperature plays an indispensable and important role in the testing process. LNE...

View details -

The necessity of temperature heating and cooling cycle in the process of catalytic hydrogenation

1683In recent years, with the rising price of oil, the demand for benzene obtained from coking benzene has increased, coupled with the country's increasing emphasis on environmental protection, the widespread application of coking benzene hydrogenatio...

View details -

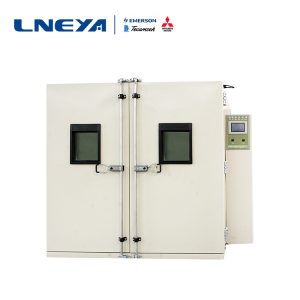

Step-by-step test box brand advantage description

1765The walk-in test box is developed and produced by LNEYA. It is specialized in pharmaceutical production technology and provides customers with various models of brands. Next, we will introduce the next step-in test box. Welcome to refer to and lea...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier