What should I pay attention to when adding refrigerant to a water-cooled chiller

In our life, we believe that everyone is

very familiar with refrigeration. In the central air conditioning and

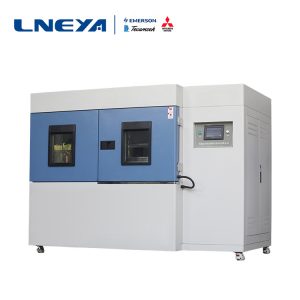

industrial production process cooling industry, small water-cooled chillers is

more common. This unit is composed of a compressor in the fuselage, a

horizontal shell and tube condenser, an evaporator, a thermal expansion valve,

and some related parts. Under the cooperation of these auxiliary parts, the

overall small water cooled chiller is compact in structure, convenient in

operation and control, and is popular among the public in the market.

For refrigeration systems that do not have

a high pressure reservoir and a low pressure vapor-liquid separator, the

control of refrigerant charge is particularly important. Because the

refrigeration system is a condenser and also acts as a high-pressure reservoir,

the refrigerant is stored in the condenser, and the condenser is cooled. The

heat dissipation area is reduced and the condensing pressure is increased,

resulting in a decrease in cooling capacity.

For the control of the refrigerant charge

of such small water-cooled chillers, the following methods are followed during

the filling process:

First, touch the temperature of the

condenser casing.

The upper outlet of the condenser outlet is

heated above the outlet, and the outlet below the outlet is cool. (There is a

description of the high temperature exhaust of the compressor in the inside.

The cooling indicates that the small water-cooled chillers is a liquid space.)

Second, look at the inspiratory pressure.

Corresponding to the temperature of the

refrigerant water in the evaporator. (That is, corresponding to the evaporation

temperature.)

Third, look at the compressor return pipe

temperature.

The high-temperature unit return pipe

should be cooled and dew, but it can be dew condensation to the compressor

return valve; the low-temperature unit return pipe should be frosted, but the

frost can be connected to the compressor return valve. If condensation or frost

builds up on the compressor casing, liquid refrigerant will enter the

crankcase, causing the compressor to run back and cause liquid

problem.

The above is a partial analysis of our

LNEYA technicians for water-cooled chillers. Regarding the specific use of our

water-cooled chillers, you can contact us sales@lneya.com for more detailed

instructions.

Related recommendations

-

Treatment of insufficient exhaust gas in high and low temperature impact test chamber compressor

1750The efficiency of the high and low temperature impact test chamber during use is very important. If there is a shortage of high compressor exhaust, we need our LNEYA technicians to solve it in time. So, how to solve it better? The high and low tem...

View details -

Effect of cooling and heating temperature cycle during emulsification

2303Emulsification is the effect of a liquid in which even tiny droplets are evenly dispersed in another liquid that is incompatible with each other. Emulsification is a liquid-liquid interface phenomenon. Two immiscible liquids, such as oil and water...

View details -

The API China exhibition is a direct hit, because of you, the harvest is wonderful!

1811The API China exhibition is a direct hit, because of you, the harvest is wonderful! Golden Autumn OctoberIt’s a good time of the year.The 83rd China International Pharmaceutical Raw Materials / Intermediates / Packaging / Equipment FairIn Nanch...

View details -

Workflow and Equipment Composition of Oil Refining and Dewaxing

1548The oil dewaxing process is based on the melting point difference between the wax and the oil and the solubility of the wax in the oil becomes smaller as the temperature decreases, and the crystalline wax is precipitated by cooling. Then through t...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier