Thermal Cycling VS Thermal Shock Testing:

What Is the Difference

The first time people watched a circuit board go through a temperature test, they were surprised by how quickly things can fail. One minute it looked fine, the next minute a corner trace had lifted. That is the reality of temperature stress.

It does not matter if you build aerospace hardware or simple automotive sensors, every part sees heat and cold in ways that are hard to predict. To sort out which designs can survive, we usually rely on two methods that sound similar but are not the same. These are thermal cycling and thermal shock testing.

On paper they may look alike, but once you run both you see how differently they push a material to its limits.

What is Thermal Cycling Testing

Thermal cycling is about repetition and slow stress. You place the sample in a chamber, set two temperature limits, and let the chamber move between them in a controlled ramp.

For instance, we often run modules from minus forty to plus one hundred twenty, back and forth, sometimes hundreds of times. The rate might be a few degrees per minute. Nothing dramatic happens in a single cycle, but the repeated expansion and contraction adds up.

What you learn from this test is not dramatic cracking, but gradual wear. Solder joints start to look dull and show micro-cracks under a microscope. Polymer seals lose their elasticity. Bolted joints loosen slightly after many runs.

It is the kind of stress you see when a car part sits outside through summers and winters, not the kind of instant break you would get in a lab shock.

What is Thermal Shock Testing

Thermal shock is different. Instead of a slow ramp, the sample goes from one extreme to the other in seconds. In our product we use a dual-chamber system. One side runs hot, sometimes two hundred degrees. The other side sits at minus sixty. A basket transfers the sample between them. In less than a minute the surface of the part has gone through a temperature jump of more than two hundred degrees.

The results are obvious even without magnification. Brittle plastics show cracks right away. Multi-layer circuit boards can delaminate between layers. Some glass coatings peel off as soon as the part comes out of the cold chamber. This is not about fatigue over time. It is about whether the design can take an extreme surprise and stay intact.

What is the Difference Between Thermal Cycling and Thermal Shock Testing

Rate of Change

The main difference starts with how quickly temperature moves. In thermal cycling the rate is measured in degrees per minute, often under control of programmable profiles.

In thermal shock the rate is almost instant, with differences of a hundred degrees or more applied in seconds. One is steady training, the other is sudden impact.

Principle

Thermal cycling is based on accumulated strain. Expansion and contraction over many repetitions work small cracks into big failures. Thermal shock works on mismatch in thermal expansion, forcing layers and joints apart before they can adjust. The physics of the two overlap, but the mechanism of damage is not the same.

Stress Type

Thermal cycling stresses build up in joints, adhesives, and solder connections because of repeated expansion. The pressure is mechanical and accumulates slowly. Thermal shock stresses are immediate and create sharp gradients across a single part. That produces tensile and compressive forces at the same time, sometimes in different layers of the same board or coating.

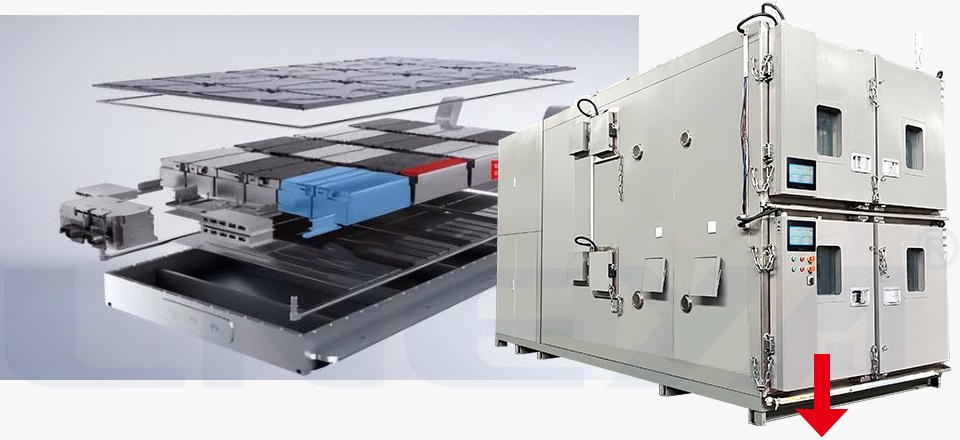

Test Equipment

A thermal cycling chamber usually has one space with heaters and refrigeration coils that ramp the temperature up and down at controlled speeds.

A thermal shock system has two or three chambers, hot and cold, sometimes with a transfer basket that drops the product quickly.

Others use fast switching airflow to slam parts with temperature extremes. Anyone who has stood beside these machines can hear the compressor kick in and feel the draft when doors seal shut.

Failure Modes

Thermal cycling tends to create fatigue cracks, gradual seal leaks, warping, and resistance drift in electronic components. Thermal shock tends to create sudden cracks, broken vias in circuit boards, shattered glass, and delamination of protective films.

When reviewing test results it is important to match the failure pattern with the stress type so you know if the part will fail slowly in service or suddenly under a worst case event.

Testing Purposes

Thermal cycling is about the long game. When we cycle a board or a module between hot and cold limits, we are asking whether it can live through years of daily use.

Small cracks in solder, slow leaks around seals, or stress that creeps into polymers usually show up after dozens or hundreds of ramps. The test is meant to imitate the kind of wear parts see on a roof-mounted controller in summer and winter, or inside an engine bay that heats and cools every time the car is driven.

Thermal shock testing does not care much about slow aging. It is meant to answer what happens when the part faces a sudden jolt of temperature.

Picture a glass-fiber board pulled straight from a 200-degree chamber and dropped into minus 60. If the part is going to crack, delaminate, or pop a coating, this is when it happens. That is why shock testing shows up so often in aerospace projects, defense hardware, or electronics cooled with liquid nitrogen.

Explore high-efficiency and energy-saving chiller solutions!

Conclusion

Cycling shows how a design handles years of steady use. Shock shows whether it can take a brutal hit on day one. Choosing the right test depends on the environment your product will face. If it lives outdoors through seasons, thermal cycling gives the right picture. If it faces rocket launches or cryogenic storage, thermal shock is the safer bet.

Rigorous material and component performance testing requires reliable thermal cycling and thermal shock chambers. LNEYA recommends our high-precision test chamber series, providing customized, safe, and accurate testing.

- Chiller Components and Refrigeration Fundamentals Guides

- Chiller Types and Selection Guides

- How Does a Peltier Cooler Work

- Peltier Chiller vs. Compressor Chiller

- What Is a Peltier Chiller

- OEM vs Aftermarket Chiller Spare Parts

- Chiller Surge

- Chiller Cooling Capacity Units

- December 2025

- November 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- September 2023

- July 2023

- June 2023

- May 2023

- January 2023

air cooled chiller chiller Chiller Installation Chiller Maintenance chiller refrigerant chillers Cold Assembly Freezer cooling chiller cooling heating system cooling system dynamic temperature control system energy efficient chiller explosion-proof chiller freezer heating circulator industrial chiller industrial chillers industrial cooling industrial freezer industrial refrigerator jacket reactor laboratory chiller low temperature chiller news oil chiller process chiller process cooling reactor chiller reactor cooling reactor cooling heating reactor heating cooling refrigerated circulator screw chiller semiconductor chiller semiconductor test chiller sundi tcu temperature control test chamber thermostat ultra low temperature chiller vehicle test chiller water chiller water cooled chiller

Related Chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier