Precision AC VS Commercial AC:What is the Difference

When people talk about air conditioning, most imagine the commercial units that keep offices, stores, or homes comfortable. Those systems work fine when the goal is general comfort.

But in data centers, laboratories, and other mission-critical spaces, a different kind of cooling is required. That is where precision AC, sometimes called precision air conditioning or PAC, comes in. Knowing how the two systems diverge helps you choose the right cooling strategy for your facility.

Basic Definitions

A commercial AC is designed for comfort cooling. Its job is to keep people comfortable in offices, retail floors, or residential spaces. These systems adjust temperature broadly, often with a tolerance of a few degrees, which is perfectly acceptable when cooling people.

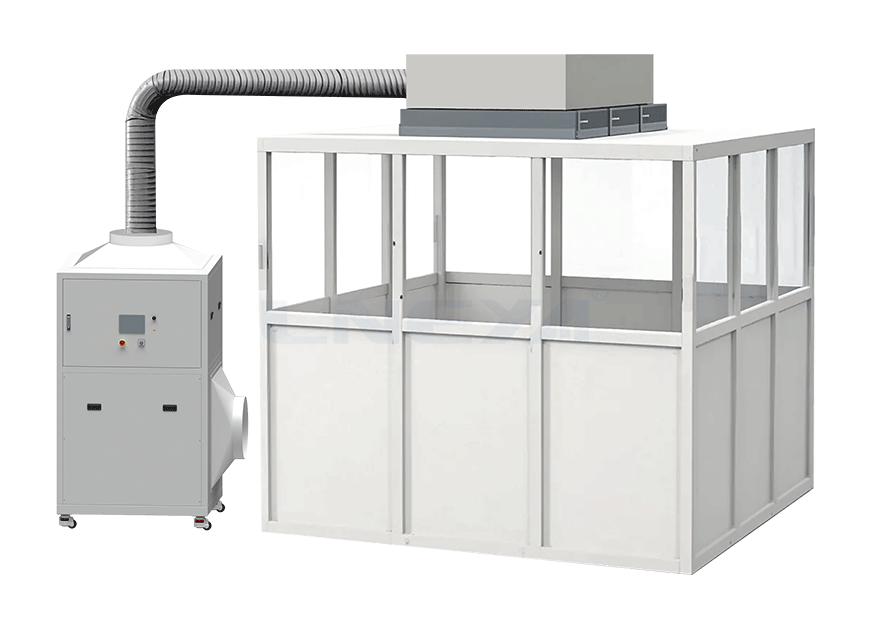

A precision air conditioner does something more demanding. It is built for equipment, not people. A PAC maintains constant temperature and humidity levels, often within a fraction of a degree or percent.

People describe it as constant-temperature and constant-humidity air conditioning. In other words, where a commercial unit focuses on comfort, a precision AC focuses on stability.

Design Purpose

Commercial AC units are optimized for short daily peaks.Precision AC units are designed with a different mission. They run 24/7, 365 days a year, often in rooms where even small fluctuations can cause failures.

A data center cannot afford a 5℃ swing. A pharmaceutical lab cannot tolerate humidity drifting out of range. A precision air conditioner is not just cooling air, it is protecting processes and data.

Control Systems and Accuracy

Commercial AC relies on standard thermostats and basic humidity control. If the system overshoots by a few degrees, nobody notices.

Precision AC uses advanced microprocessor controls. Sensors constantly track air temperature, return air, supply air, and humidity. Adjustments happen in real time, often within seconds. Precision air conditioning can hold setpoints within ±1°℃ and ±1% relative humidity, something a standard comfort system simply cannot achieve.

Air Filtration Efficiency

In most commercial environments, air filtration is basic. The filters catch dust and pollen, which is enough for human comfort.

In contrast, precision AC often integrates high-efficiency filters to protect sensitive equipment. Electronics, lab instruments, and cleanroom processes cannot be exposed to fine particles. That is why PAC systems are usually paired with better filtration stages and airflow management. The design ensures not only steady temperature but also clean air around sensitive equipment.

Purchase and Operating Costs

It is true that a precision air conditioner costs more upfront. Certified components, advanced controls, and continuous-duty design increase the price. Operating costs can also be higher because the unit is built to run without pause, often with redundancy.

But our engineers remind customers to consider the total cost of ownership. A commercial AC that fails in a data center could mean millions in downtime. In comparison, the added cost of a PAC is a form of insurance. Over time, the investment pays back by preventing outages and protecting assets.

Application Differences

Commercial AC belongs in offices, retail buildings, schools, and residential spaces. The mission is human comfort, not technical precision.

Precision AC belongs in environments where equipment or processes require strict control. The projects include data centers, telecom shelters, medical imaging rooms, semiconductor facilities, and high-end manufacturing labs. In these spaces, even a small deviation in temperature or humidity can cause serious damage. A spot cooling solution is added to target specific hot zones within these facilities, something a comfort unit cannot do.

Conclusion

Both commercial AC and precision AC have their place. One is designed to keep people comfortable. The other is designed to keep equipment and processes safe. If your facility depends on stable conditions, a precision air conditioner is the right choice.

Our experts at LNEYA have worked with PAC systems across industries, from data centers to chemical plants. Contact us today to discuss how a precision AC solution can protect your operation.

- Chiller Components and Refrigeration Fundamentals Guides

- Chiller Types and Selection Guides

- How Does a Peltier Cooler Work

- Peltier Chiller vs. Compressor Chiller

- What Is a Peltier Chiller

- OEM vs Aftermarket Chiller Spare Parts

- Chiller Surge

- Chiller Cooling Capacity Units

- December 2025

- November 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- September 2023

- July 2023

- June 2023

- May 2023

- January 2023

air cooled chiller chiller Chiller Maintenance chillers Cold Assembly Freezer cooling chiller dynamic temperature control system energy efficient chiller heating circulator industrial chiller industrial chillers industrial cooling industrial freezer industrial refrigerator jacket reactor laboratory chiller low temperature chiller news process chiller process cooling reactor cooling reactor heating cooling refrigerated circulator screw chiller semiconductor chiller semiconductor test chiller sundi tcu temperature control test chamber thermostat ultra low temperature chiller vehicle test chiller water chiller water cooled chiller

Related Chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier