Industrial Chiller Filters Explained

Industrial chillers are used in many industries to help control the temperature of equipment and processes. However, chiller systems are highly sensitive, and the ingress of moisture and solid particles can clog heat exchangers, corrode pipes, and even damage equipment. To prevent such issues, chiller filters are used to remove impurities from the coolant, refrigerant, cooling water, and air. Filter types and specifications vary depending on the installation location and the impurities to be filtered.

Cooling Water Circuit Filters

To save costs, many water-cooled chillers use tap water or groundwater for cooling water. These sources often contain solid particles such as silt, which can easily settle in heat exchangers and cause clogging. Filters used in cooling water circuits primarily filter large particles such as silt, rust, welding slag, scale, and algae. They are typically installed before the water pump, at the return inlet of the water tank, or on the inlet and outlet pipes.

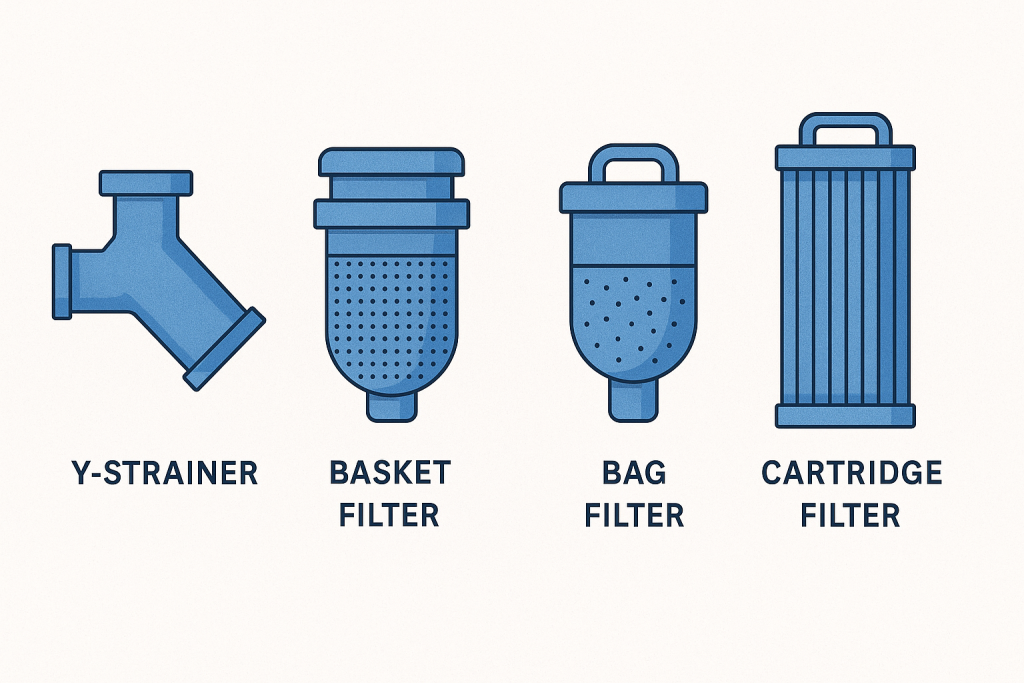

Y-strainers, basket filters, and bag filters are used in this circuit. The Y-strainer has a simple structure and is suitable for coarse filtration. It can be disassembled, cleaned, and reused repeatedly, resulting in low cost. Basket filters have a large mesh area and are generally used in pipelines with relatively high flow rates. Bag filters have a fine mesh that can trap finer particles and are used in precision filtration, such as medical chillers and semiconductor chillers.

Coolant filters

Low-temperature chillers typically use a chiller fluids such as thermal oil or glycol-water mixtures. After prolonged use, this mixture may mix with oxides in the pipes, deteriorate, and produce suspended solids. If not promptly intercepted, it can easily clog the heat exchanger channels. Filters in coolant circuits are generally installed at the inlet of the circulating pump or before entering the cooling point of the equipment or process.

Because they need to filter fine particles, filters with more precise filter elements are required, such as micron-rated bag filters and magnetic filters. The filter bags in micron-rated bag filters have micron-sized pores, enabling them to capture submicron impurities. Magnetic filters use a permanent magnet mounted in a stainless steel housing. Due to its magnetic field, iron filings, steel powder, and rust residue in the liquid flowing through the filter are attracted to the magnet. Their advantage is that they are not mesh-like, so adsorbing impurities does not cause significant pressure drop or clogging.

Refrigerant side filters

Filters in the refrigerant circuit primarily prevent moisture and acidic substances from corroding the system, and solid particles from causing wear to the compressor. They are typically installed between the compressor and the expansion valve, but some systems also install a suction line filter on the compressor suction side or in the oil return line.

Common filter types in this circuit are filter-driers, suction line filters, and replaceable core filter-driers. Filter-driers contain desiccants such as molecular sieves and activated alumina, along with a filter screen. The desiccant absorbs moisture, while the filter screen intercepts solid particles. Suction line filters intercept large particles before the refrigerant enters the compressor. Replaceable core filter-driers can accommodate interchangeable filter cores and can be replaced with filter elements for different functions, such as drying, acid absorption, and dewaxing.

Air filters

To prevent dust, oil mist, and particulate matter from entering the air and affecting the heat exchange efficiency of the condenser, air filters are installed at the air inlet and air exchange port of air-cooled chillers.

Primary filters, metal mesh filters, and multi-layer fiber filtersare commonly used. Primary filters are constructed from multiple layers of interwoven synthetic fibers, non-woven fabrics, nylon mesh, or glass fibers, and are used to filter large particles such as dust, hair, and pollen. Metal mesh filters are typically made of stainless steel, copper, or aluminum and are also used to filter coarse particles.

Multi-layer fiber filters, constructed from chemical fibers such as polyester and glass, can capture aerosolized oil droplets and smoke. Although disposable, these filters hold a large amount of dust and require a long replacement cycle.

Conclusion

A trustworthy chiller supplier will select the appropriate filter for your equipment based on its type, refrigerant, and coolant. At LNEYA, we design and manufacture water-cooled chillers, air-cooled chillers, and DX systems with various performance levels. These chillers are used by customers in over 30 countries and regions worldwide in applications in pharmaceutical, new energy, semiconductor, chemical, and other industries.

Contact us for a chiller catalog and technical support.

- Chiller Components and Refrigeration Fundamentals Guides

- Chiller Types and Selection Guides

- How Does a Peltier Cooler Work

- Peltier Chiller vs. Compressor Chiller

- December 2025

- November 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- September 2023

- July 2023

- June 2023

- May 2023

- January 2023

Related chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier