Semiconductor Temperature Forcing System Thermal Flow Hood for DUT Testing

The semiconductor temperature forced system (TFS), thermal flow meter and thermal flow hood are important equipment used to test the performance of semiconductor devices under different temperature conditions. These equipment are usually used for testing semiconductor chips, packages and modules to evaluate their thermal performance and reliability at different temperatures.

Semiconductor Temperature Forced System (TFS)

Overview:

• TFS is a test system used to simulate and control the operating temperature of semiconductor devices. It can accurately control the operating temperature of semiconductor devices so that they can operate under different temperature conditions to evaluate the thermal performance and reliability of the devices.

Composition:

• Temperature controller: used to set and control the temperature of semiconductor devices.

• Heating/cooling system: used to heat or cool semiconductor devices to reach the set temperature.

• Temperature sensor: used to monitor the actual temperature of semiconductor devices.

• Data acquisition system: used to record temperature data and other related test data.

Application:

• Thermal performance test: evaluate the thermal resistance, thermal diffusion performance, etc. of semiconductor devices under different temperature conditions.

•Reliability test: evaluate the performance stability of semiconductor devices under high or low temperature conditions.

Thermal Flow Hood

Overview:

•Thermal Flow Hood is a special test equipment used to wrap semiconductor devices to form a closed thermal environment to measure the heat flow of the device.

Composition:

•Thermal Flow Hood Body: Usually made of materials with good thermal insulation properties to reduce the impact of the external environment on the test results.

•Temperature sensor: used to monitor the temperature inside and outside the thermal flow hood.

•Data acquisition system: used to record temperature data and other related test data.

Application:

•Thermal performance evaluation: used to evaluate the thermal performance of semiconductor devices under actual working conditions.

•Packaging performance evaluation: used to evaluate the thermal properties of semiconductor packaging materials, such as thermal resistance and thermal diffusion properties.

DUT (Device Under Test) refers to the semiconductor device under test, which is the focus of the entire test process. When testing with TFS, thermal flow meter and thermal flow hood, the DUT is usually precisely controlled under the required temperature conditions and its thermal performance is evaluated.

Summary Semiconductor temperature forcing systems, heat flow meters, and heat flow hoods are important tools for evaluating the thermal performance and reliability of semiconductor devices. With these devices, the operating temperature of semiconductor devices can be precisely controlled and their heat flow can be measured to evaluate the thermal performance and reliability of the devices under different temperature conditions. These tests are essential to ensure the performance stability and reliability of semiconductor devices in actual applications.

Related recommendations

-

-

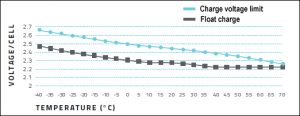

Is it right to extend battery life by lowering the ambient temperature?

1478The battery can work in a wide temperature range, but this does not allow the battery to be charged under high temperature conditions. The charging process is more delicate than the discharging process, and extreme care must be taken. Extreme cold...

View details -

Classification and Application of Industrial Water Chillers

1816In lots ofindustrial production processes, it is difficult to obtain high efficientindustrial production efficiency if there is no industrial water chiller toprovide a low temperature production environment. Therefore, industrial water chill...

View details -

Use of electric vehicle battery chillers in the applied industry

1713In the electric vehicle industry, the battery pack is one of its main components, with high difficulty and complex nature, so the choice of chiller for its testing is also very important. The LNEYA electric vehicle battery chiller provides a solut...

View details -

Classification and advantages and disadvantages of water-cooled chillers

1921Industrial chillers are divided into air-cooled industrial chillers and water-cooled industrial chillers. Today we will discuss the classification, advantages and disadvantages of water-cooled chillers. Advantages of water-cooled chillers: 1. Inte...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier