Dr Series Gas Dryer

APPLICATIONS

Use in sensors, semiconductor manufacturing, film and packaging material licenses, powder material transportation, spraying systems, food industry, pharmaceutical industry, etc. require distributed air sources with low dew point of -80℃ dry and clean.

Product Features

Product Parameters

| Mode | DR-300 | DR-600 | DR-1200 |

| Pressure range | 0.65~1.0Mpa | ||

| Dew point temperature | -70℃ | ||

| Gas processing capacity | 425L/Min | 900L/Min | 1750L/Min |

| Finished gas volume | 300L/Min | 600L/Min | 1200L/Min |

| Connection Size | ZG1/2 | ZG1/2 | ZG3/4 |

| Power | 220V 15W | ||

| Dimension cm | 200*180*1250 | 450*180*1250 | 450*180*1250 |

Distributed gas sources used in sensors, semiconductor manufacturing, film and packaging material licensing, powder material transportation, spraying systems, food industry, pharmaceutical industry, etc. that require -80℃ low dew point drying and cleaning.

Additional filtration of oil and particulate matter, with airflow passing through a filtration level of 0.01 μm, the pre filter prevents the desiccant from being contaminated by dust and oil (which greatly shortens the lifespan of the desiccant).

The compressed air dryer consists of multiple sets of filter cartridges filled with desiccants. The compressed air in the form of mist alternately flows through multiple sets of filter elements, and the moisture in the air will accumulate on the surface of the dryer. After the filtration process reaches a predetermined duration, the airflow will switch to other filter elements, and a portion of the airflow (discharge airflow) will be used to regenerate the dryer of the first filter element. The flushing airflow will be released into the atmosphere. The service life of desiccants is approximately 15000 working hours.

Product Advantages

- Efficient production stability and repeatability results;

- Using plate heat exchangers and pipeline heaters to improve cooling and heating rates;

- Very wide temperature range, no need to replace liquid medium;

- Fully enclosed system, extending the lifespan of thermal conductive liquids;

- Adopting magnetic drive pump, there is no problem of shaft seal leakage;

- High temperature cooling technology, directly start the compressor to cool down at 300 ℃.

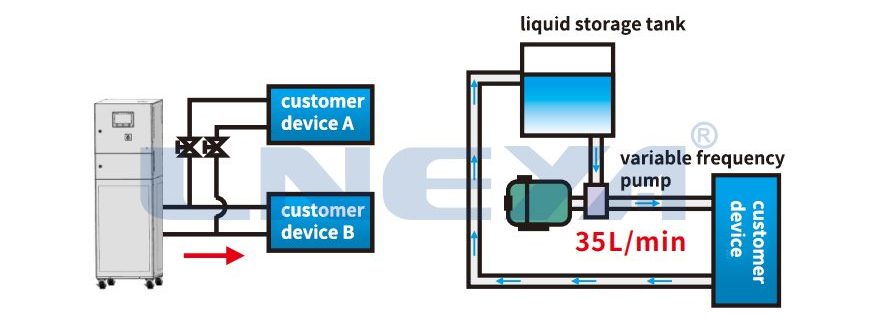

Variable frequency pump can adjust circulating hydraulic pressure and flow

client output signal

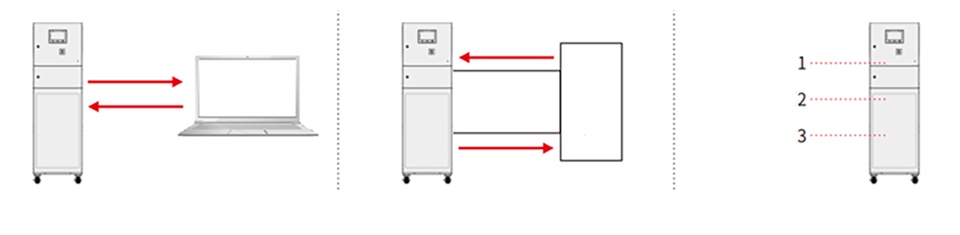

Communication function

APPLICATIONS

Such as chillers that control the processing temperature on the Fab equipments.

Cooling of CMOS/CCD sensors in semiconductor metrology systems.

Recirculating Chiller for semiconductor metering AOI system.

Single channel air-cooled cooler, mainly designed for etching machines. It is used to provide independent temperature control for the chamber side walls.

Used for plasma bevel etch and deposition; Thermal Atomic Layer Etching of Metal Tungsten.

LNEYA provides customized Chiller services

custom chiller sizes

Whether it is portable, compact, large and small chillers, we can custom design them according to your requirements. No matter how many tons of chiller you need, we can create the best solution.

custom chiller types

We provide chillers of various refrigeration types, including but not limited to air-cooled, water-cooled and evaporative-condensing chillers. Regardless of the type of refrigeration compressor, we can design it according to your requirements.

custom temperature ranges

We can create a custom solution for temperatures from -150℃ to +350℃. Custom temperature ranges for specific industries.

custom chiller voltage

Customize chiller voltage and phase according to your needs. Optional 110V/60HZ, 220V/60HZ, 380V/50HZ, 220V/50HZ, 400V/50HZ, 460V/60HZ, 440V~480V/60HZ, etc.

Visit LNEYA factory

Why choose lneya as your temperature control supplier?

Years of experience

Satisfied Customers

m² Production Area

Patented Technologies

contact us

Submit your request to us and we will contact you within 24 hours

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier