Efficient method for extracting total cannabinoids using a cryogenic process cooling system

Although cannabis plants have been used for medicinal purposes for thousands of years, modern science has identified steroids, flavonoids and more than 100 therapeutically active compounds known as cannabinoids.

Due to the significant synergy between different cannabinoids and terpenes (aromatic oils responsible for the aroma of cannabis plants), it is more beneficial to use natural cannabis based formulations rather than any single purified or synthetic cannabinoid.

As more and more governments and their states legalize the medicinal use of cannabis, there must be a safe and effective way to extract and isolate plant cannabinoids.

Alcohol extraction is the oldest and most common method of plant extraction. It has excellent solubility in lower alcohols such as ethanol and isopropanol, and cannabinoid extraction is effective as long as the water content in the alcohol is small. Prior to the ban, ethanol cannabis tinctures are part of the traditional pharmacopoeia and can be obtained from corner pharmacists.

Although many lower alcohols are suitable for efficient cannabinoid extraction, the extraction industry preferably uses ethanol due to its availability, handling and health safety, and it does not require high pressure extraction. Most interestingly, extraction with ethanol will produce a full spectrum extract that contributes to the synergistic activity of the plant cannabinoids to exert superior pharmacological activity.

Ethanol contains polar and non-polar moieties that dissolve hydrophilic and hydrophobic molecules. The polar group of ethanol dissolves hydrophilic compounds such as chlorophyll, pigment and tannin. The non-polar groups of ethanol are used together with hydrophobic ingredients such as vegetable waxes/fats, oils, cannabinoids, terpenes, and any other substances present inside or outside the plant.

On average, cannabis plant shoots produce about 12.5% of the extract concentrate. Since the buds must be completely covered during extraction, the solvent volume to plant mass ratio must be about 20 or higher, which reduces the feasibility of the process and project because a large amount of solvent ethanol must be distilled off.

Regardless of the solvent used for extraction, the extractor and extraction process must be carefully and appropriately designed in the plant cannabinoid extraction industry to obtain maximum yield with maximum cannabinoid without any thermal degradation in the extract. This level of quality is achieved by using temperature parameters and other physical process steps in the extraction.

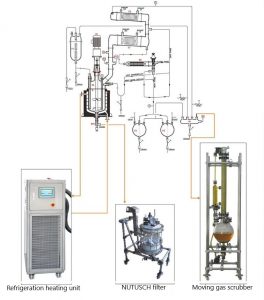

Temperature is an important step in the extraction process. Methods and equipment systems are indispensable. The Lneya cryogenic refrigeration system is essential as a cooling solution in the extraction process.

Related recommendations

-

-

Why do chemical raw materials require low-temperature chillers?

1447The main reasons for using low-temperature chillers in the production process of chemical raw materials are as follows: Temperature control: Many chemical reactions are temperature sensitive and require precise temperature control to...

View details -

LNEYA fights against “NCP” and resumes production safely

2130The NCP casts a haze over the new year of 2020, but the moment when everything recovers will never be absent. At present, for many enterprises across the country, their operating pressure and shoulder responsibility are very heavy. However, LNEYA ...

View details -

-20 ° C freezer manufacturers choose what to look at the evaporator?

1843In the process of producing industrial freezer, the selection of a suitable evaporator is also very important for the freezer, because the choice of suitable evaporator is better for better operation of the -20 °C freezer. The evaporator is genera...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier