Hybrid car battery test equipment cooling capacity description

Due to insufficient insulation thickness of the hybrid vehicle battery test equipment and pipeline or damage to the insulation layer, the loss of cooling capacity is increased, which affects the cooling effect. In the operation of the hybrid vehicle battery test equipment, once the outer surface of the insulation layer is found to have wet or frosted parts, it means that the thickness of the insulation material is insufficient or has been damp, and the insulation material should be added or replaced in time.

When the equipment is installed, a layer of insulation cotton is placed on the evaporator and the pipeline to prevent loss of cooling capacity. If the hybrid vehicle battery test equipment is slow in cooling, first check whether the thickness of the pipe insulation layer is not enough, or if the insulation layer is damaged, be sure to pack the insulation cotton and ensure that the thickness is sufficient!

Check for air in the equipment cooling system. When installing the hybrid vehicle battery test equipment, whether it is inside the unit, water pump, or pipeline, there can be no air, even if there is only a little air, the cold hybrid vehicle battery test equipment can not operate normally. In addition, there is a film inside the pump, and you must remember to tear it off before installation. Otherwise, the circulating water has no way to circulate or the circulation is very slow, which directly affects the operation of the hybrid vehicle battery test equipment.

Check the moving parts of the refrigeration compressor of the hybrid vehicle battery test equipment for wear, or increase the clearance, resulting in a decrease in the volume of gas. The compressor is the heart of the cooling water machine. If there is a problem with the compressor, the hybrid vehicle battery test equipment will not work. Therefore, the periodic inspection and maintenance of the compressor cannot be ignored.

The poor efficiency of equipment refrigeration compressors is also one of the reasons. In the long-term operation of the hybrid vehicle battery test equipment, the wear of the moving parts, the increase of the matching clearance or the tight sealing will reduce the actual air volume of the compressor and reduce the cooling capacity. Check the refrigeration compressor. If the repair is not good, it should be replaced in time. Air in the system can also cause this to happen. At this time, the exhaust pressure and temperature increase, the power consumption increases, and the cooling capacity decreases.

The cooling of the hybrid vehicle battery test equipment is related to the data of the hybrid vehicle battery test process, so the cooling capacity needs to be better according to the requirements.

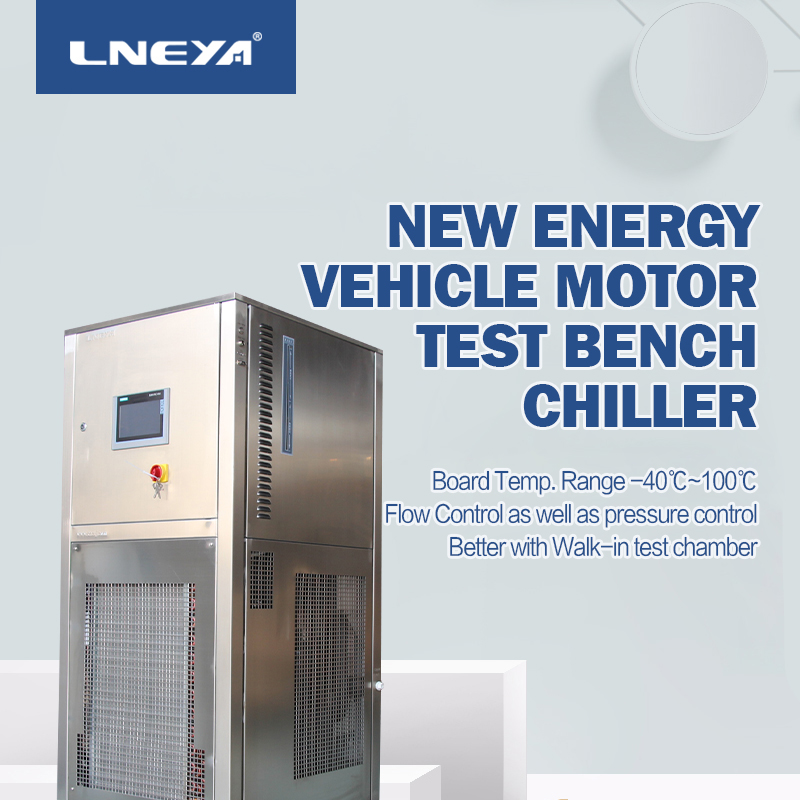

Industrial Chillers Manufacturer Supplier - LNEYA

Industrial Chillers Manufacturer Supplier - LNEYA