Industrial Chillers for Japan’s Manufacturing Industry

In Japanese factories, production runs fast and tolerances are tight. Anyone who has worked on a line knows that a small shift in temperature can upset the process—whether it’s a coating oven, a test chamber, or a water-cooled spindle. The role of the chiller is simple but critical: keep that cooling loop steady so the machines don’t drift out of spec.

Challenges for Temperature Control Systems in Japan’s Manufacturing Industry

Equipment Sensitivity

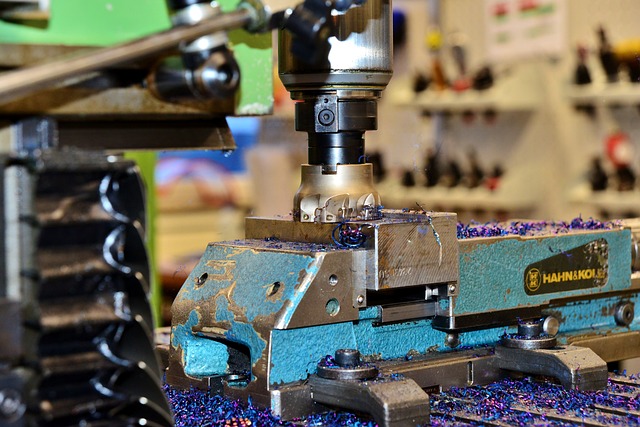

CNC machines, paint booths, and semiconductor photolithography tools are built to deliver repeatability down to microns. The catch is that these machines are sensitive to heat. It doesn’t take much to cause trouble. A change of just a couple degrees might throw off dimensions or shut a tool down. That’s why in many plants you’ll see requirements like ±0.1°C stability written into the spec sheet. The chiller has to hold that line for long shifts without wandering.

Limited Factory Space

Unlike plants in regions with wide industrial zones, many Japanese factories sit inside dense urban areas. Space is expensive, and floor layouts are often compact. Space is another headache. Many facilities can’t just drop in a huge cooling tower or oversized chiller. Floor plans are already packed. Engineers end up leaning on compact, modular systems that can slide in next to existing equipment without blocking operators or material flow.

High Energy Costs

Energy costs bite hard in Japan, more so in regions that depend on imported fuel. Every kilowatt matters when you add up the monthly bill. Old-style chillers that hammer away at full load aren’t practical anymore. Plants are moving toward variable-speed drives, smarter control logic, and even heat recovery, anything that cuts demand spikes and trims power use.

Maintenance Constraints

Production doesn’t stop for long. On a car line or in a pharma clean room, downtime isn’t just inconvenient—it costs real money. The equipment has to run steady for long stretches, and maintenance teams need early warning when something starts drifting. That’s why remote monitoring and predictive tools are showing up everywhere.

How Industrial Chillers Address These Challenges?

Precise Temperature Control

Industrial chillers engineered for Japanese markets use high-accuracy sensors and tight PID loops. In semiconductor fabs, for example, FLTZ series semiconductor chillers stabilize water temperature within fractions of a degree. That stability keeps photolithography lines producing clean patterns without distortion.

Compact, Modular Design

Instead of single oversized chillers, modular racks are installed that scale with production needs. Units like LNEYA’s KRY series battery test chillers are built to slide into existing layouts, providing reliable cooling without eating up valuable space. Expansion is as simple as adding another loop.

Variable Frequency and Smart Controls

Compressors with VFDs adjust their speed to match real-time load. When production slows, power consumption drops. When it ramps up, the chiller responds smoothly. Smart controls also allow multiple units to balance demand, trimming peak loads that would otherwise inflate energy bills.

Remote Monitoring

IoT-enabled chillers push live data to dashboards, giving maintenance teams a clear picture of performance. Modern systems flag problems early, maybe a drop in flow or a slight pressure change, before they snowball into a shutdown. That kind of visibility lets factories plan a service window on their terms instead of scrambling after a breakdown.

Key Japanese Manufacturing Industries Using Industrial Chillers

Automotive Manufacturing

Automotive plants in Japan are famous for their precision. But machining steel blocks, curing paint, or testing EV batteries generates heat that has to be managed. Equipment is sensitive, and product tolerances leave no room for temperature drift.

KRY series chillers are a common choice here, especially for battery tests. They hold steady conditions during long test cycles, whether it’s an engine endurance run or a battery charge-discharge simulation. Compact modular design also makes them fit into crowded plants without major layout changes.

Semiconductor & Electronics

Few industries demand tighter thermal stability than semiconductors. A photolithography machine can stop if water temperature varies by more than a fraction of a degree. Electronics assembly lines face similar issues when soldering or inspection systems overheat.

FLTZ series chillers provide ultra-precise water cooling, often at ±0.05°C stability. With variable frequency drives and intelligent control, they deliver consistency while consuming less energy.

Pharmaceutical & Biotechnology

Fermentation tanks, reactors, and clean room environments all need strict temperature control. A few degrees off can compromise an entire batch. LT and LTZ series chillers, along with the SUNDI dynamic temperature control systems, are widely used in these plants.

They provide fast response, wide temperature ranges, and stable long-term operation. Engineers value their ability to support both R&D scale work and continuous production lines.

Chemical & Fine Chemical Industry

Chemical reactions release heat unpredictably. If not managed, yields fall, or worse, safety incidents occur. Japanese chemical plants rely on chillers that can pull heat out quickly and run for long cycles without interruption.

LG screw compressor chillers, LTZ recirculation chillers and SUNDI chiller heater systems handle this environment well. They cool reactors, condensers, and process water loops efficiently, with the added benefit of remote monitoring. This keeps operators in control of processes that can’t afford instability.

Explore high-efficiency and energy-saving chiller solutions!

Conclusion

Looking for a temperature control system that fits your unique application? LNEYA’s product line includes refrigeration systems, heating systems, and dynamic temperature control systems (cooling and heating). We offer standard equipment and one-stop customization services.

Contact us to discuss your needs or get a detailed quote.

- Chiller Components and Refrigeration Fundamentals Guides

- Chiller Types and Selection Guides

- How Does a Peltier Cooler Work

- Peltier Chiller vs. Compressor Chiller

- What Is a Peltier Chiller

- OEM vs Aftermarket Chiller Spare Parts

- Chiller Surge

- Chiller Cooling Capacity Units

- December 2025

- November 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- September 2023

- July 2023

- June 2023

- May 2023

- January 2023

air cooled chiller chiller Chiller Installation Chiller Maintenance chiller refrigerant chillers Cold Assembly Freezer cooling chiller cooling heating system cooling system dynamic temperature control system energy efficient chiller explosion-proof chiller freezer heating circulator industrial chiller industrial chillers industrial cooling industrial freezer industrial refrigerator jacket reactor laboratory chiller low temperature chiller news oil chiller process chiller process cooling reactor chiller reactor cooling reactor cooling heating reactor heating cooling refrigerated circulator screw chiller semiconductor chiller semiconductor test chiller sundi tcu temperature control test chamber thermostat ultra low temperature chiller vehicle test chiller water chiller water cooled chiller

Related Chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier