How to Upgrade an Old Chiller to Improve Efficiency

If you’ve been running the same chiller for years, you might have noticed it’s not quite the workhorse it used to be. Maybe the power bill keeps creeping up. Maybe the supply temperature drifts more than it should. Or maybe you’ve had to call the service tech one too many times this year.

An aging chiller doesn’t just cost more to operate — it can put your production schedule, product quality, and even workplace safety at risk. The good news? You don’t always need to replace it entirely. With the right approach, a chiller upgrade can bring new life to an old system and improve efficiency far beyond what you might expect.

Common Problems with Old Chillers

Before talking solutions, let’s look at why older chillers lose their edge over time.

Energy Efficiency Drops

It’s normal for efficiency to decline as components wear. Bearings loosen. Heat exchanger surfaces foul. Control logic gets outdated. A chiller that once ran at peak performance might now be drawing more kilowatts for the same ton of cooling.

Temperature Control Becomes Unstable

When sensors drift out of calibration or valves stick, it becomes harder to maintain tight temperature tolerances. For industries like pharmaceuticals or electronics, that’s more than an inconvenience — it’s a production risk.

Frequent Breakdowns

Old chillers often suffer from recurring failures. Pumps, compressors, and fans have finite life spans. Once a unit reaches a certain age, the downtime costs can outweigh the repair costs.

Outdated Refrigerants

We still run into chillers that use R22 or other refrigerants that have been phased out for years. If yours is one of them, you already know the drill — the refrigerant is expensive, harder to get every year, and there’s always that worry about compliance. In some cases, the cost of a recharge is almost as much as a small retrofit project. It’s not just an environmental issue anymore; it’s an operational headache.

No Connectivity for Modern Systems

Another thing with older units is how “disconnected” they feel compared to today’s systems. A lot of them were built before IoT or building automation became standard.

That means no remote monitoring, no quick way to check performance trends, and no alerts before something goes wrong. You end up finding out there’s a problem when production slows or stops — not exactly the kind of predictive maintenance anyone wants.

Why Upgrade Your Chiller Instead of Just Replacing It?

Upgrading can be a smart middle ground between doing nothing and buying a whole new system.

Boost Efficiency

Modern components — from high-efficiency compressors to EC fans — can cut energy use significantly. Even a partial retrofit can pay for itself quickly in reduced utility bills.

Extend Equipment Life

An upgrade chiller project can add years to the life of your system. By replacing the parts under the most stress, you can delay the big capital expense of a full replacement.

Improve Temperature Control

Upgraded controls and sensors help maintain stable process temperatures, even when loads change quickly. This is especially important for sensitive manufacturing processes.

Increase Safety and Sustainability

Switching to low-GWP refrigerants and adding better leak detection improves safety for your staff and reduces environmental impact. It also keeps you ahead of tightening regulations.

How to Upgrade an Old Chiller for Better Performance?

Not all chiller upgrades look the same. The right approach depends on your budget, your system’s age, and your performance goals.

Replace Critical Components

Sometimes the biggest efficiency gains come from swapping out key hardware:

• Compressors: Newer models can be 10–20% more efficient and offer variable speed for better load matching.

• Heat Exchangers: Replacing corroded or fouled units restores heat transfer capacity.

• Fans and Pumps: High-efficiency motors and variable frequency drives (VFDs) improve part-load performance.

These changes can transform an old chiller from a constant headache into a steady, reliable asset.

Add Supporting Equipment

A chiller upgrade isn’t just about the chiller itself. Adding the right auxiliary gear can solve persistent problems.

• Buffer Tanks: Prevent short-cycling by adding thermal mass.

• Expansion Tanks: Keep pressure stable and protect piping.

• Advanced Filtration: Keeps the water loop clean, reducing scale and corrosion.

These relatively low-cost additions can extend maintenance intervals and stabilize system operation.

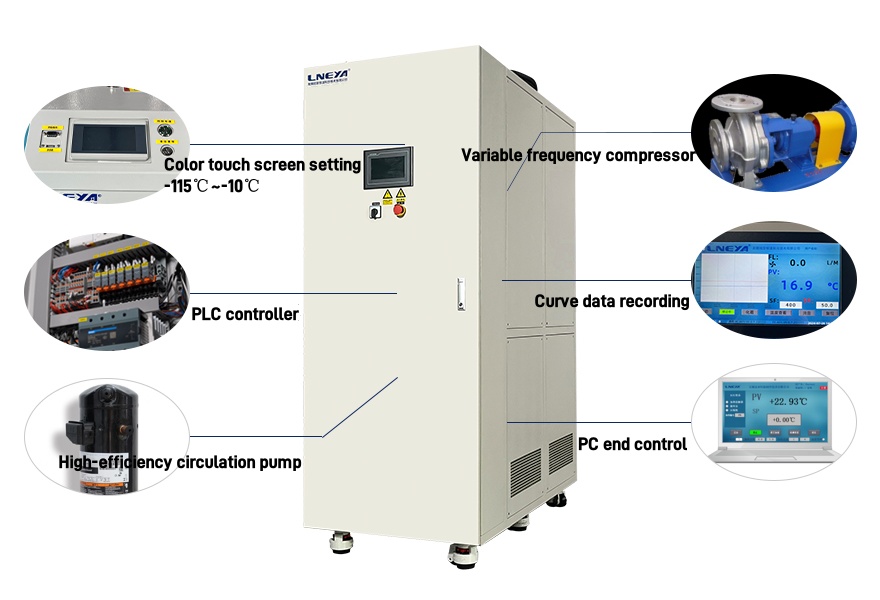

Integrate Smart Controls

Even the best hardware can’t reach its potential without smart control. Many older chillers still rely on fixed setpoints and basic logic. Modern control systems offer:

• Real-time performance monitoring

• Predictive maintenance alerts

• Remote access for off-site supervision

• Dynamic load adjustment based on demand

A control upgrade can make your chiller feel like a brand-new machine, even if the frame and core components are decades old.

Think About Going All-In with a New Unit

If yours is pushing past two decades, still running on a refrigerant that’s impossible to source, or has multiple big-ticket parts on their last legs, buying new can actually be the cheaper move over the long run.

A fresh unit doesn’t just run quieter and cooler — it’s built with the latest compressor tech, low-GWP refrigerants, and smart controls that talk to your building system without extra hardware. You get better efficiency and no more scrambling for obsolete parts.

Conclusion

In many cases, a few well-chosen upgrades can stretch the machine’s life and cut operating costs. In others, replacement really is the better bet.

If you’re not sure, get someone who knows chillers inside out to look it over. They can tell you straight if it needs a new compressor, a control upgrade, or a spot on the scrap list.

Here at LNEYA, we design and customize chillers for everything from tight-tolerance lab cooling to heavy-duty industrial processes. We can retrofit your current system, supply you with a more efficient replacement, or design something from the ground up for your exact application.

Give us a call or drop us a message — we’ll help you get a cooling system that runs the way it should, day in and day out.

- Chiller Components and Refrigeration Fundamentals Guides

- Chiller Types and Selection Guides

- How Does a Peltier Cooler Work

- Peltier Chiller vs. Compressor Chiller

- What Is a Peltier Chiller

- OEM vs Aftermarket Chiller Spare Parts

- Chiller Surge

- Chiller Cooling Capacity Units

- December 2025

- November 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- September 2023

- July 2023

- June 2023

- May 2023

- January 2023

air cooled chiller chiller Chiller Installation Chiller Maintenance chiller refrigerant chillers Cold Assembly Freezer cooling chiller cooling heating system cooling system dynamic temperature control system energy efficient chiller explosion-proof chiller freezer heating circulator industrial chiller industrial chillers industrial cooling industrial freezer industrial refrigerator jacket reactor laboratory chiller low temperature chiller news oil chiller process chiller process cooling reactor chiller reactor cooling reactor cooling heating reactor heating cooling refrigerated circulator screw chiller semiconductor chiller semiconductor test chiller sundi tcu temperature control test chamber thermostat ultra low temperature chiller vehicle test chiller water chiller water cooled chiller

Related chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier