How to solve the fault of the ultra-low temperature refrigerator pressure controller?

If the industrial ultra-low temperature refrigerator encounters a controller-related failure during operation, if it is not resolved in time, the pressure controller may be unavailable.

The pressure controller plays a very important role in the ultra-low temperature refrigerator group. Because of the pressure exerted between each accessory under the high-efficiency working state, the range is different.

In order to reduce the impact of pressure on the ultra-low temperature refrigerator group, the company should regularly check the pressure controller carefully. Only careful inspection can ensure that the equipment operates within a stable and safe pressure range, and the pressure is stable. The problem will be reduced accordingly.

So, where is the pressure controller? The pressure control unit is installed in different positions and there will be different pressures. The range of settings is different, and the effect on the ultra-low temperature refrigerator group is also different. The principle of high pressure and low pressure is different, and the scope of protection for intelligent ultra-low temperature refrigerators is also different. In actual use, there may be excessive pressure, or the pressure is too small. Naturally, there are some internal causes. If you let it develop, it will have a bad influence on the machinery. At this time, the equipment will be It will be a self-protection method by powering off. By reducing this gap, you can try to make the equipment less problematic and the life will increase accordingly. Therefore, it needs to operate within a very safe pressure range. The technology will run steadily.

For ultra-low temperature refrigerator users, the company should ask technicians to train these personnel to let them know the maintenance expertise, what should be checked, and which conditions should be taken care of.

If the relevant configuration of the ultra-low temperature refrigerator is relatively high, the pressure controller failure is relatively small, so it is recommended to choose a reliable manufacturer to purchase.

Related recommendations

-

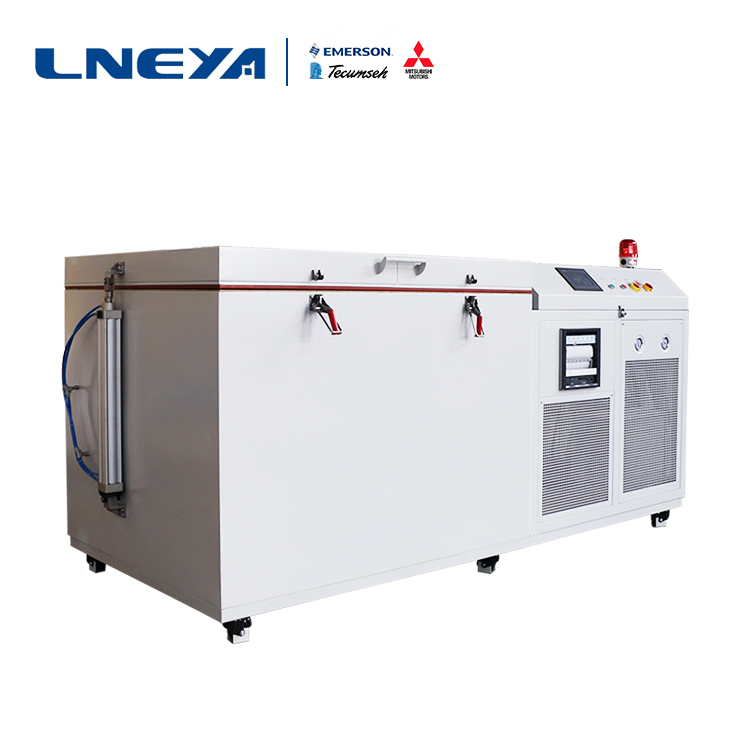

-220 °C refrigerator installation instructions

1552The appearance and weight of different models of -220 °C refrigerator are different, so the installation is also important. -220 °C refrigerator should be placed indoors, should be placed in a solid and flat place, in order to reduce the vibration...

View details -

Why is the mode of cooling water circulator mainly water circulation?

1370Cooling water circulator is a way to use water for cooling. With the increase in ambient temperature, many companies have also found that the use of circulating water is increasing. The supplement of circulating water is aimed at the water cooling...

View details -

How to clean air control system?

1844In order to respond to the requirements of the two types of society in the country, environmental protection and conservation have become increasingly important. Therefore, in order to extend the life of the product, it is still necessary to have ...

View details -

Comparison of Three Test Methods for Low Temperature Chamber

18012. Non-heat dissipation test samples and heat dissipation test samples When the temperature of the test sample is stable during the conditional test period, the hottest spot temperature on the surface of the test sample is higher than the ambient ...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier