What is the Chiller Expansion Valve?

In industrial chillers, expansion valves is used to control refrigerant flow .Expansion valves of various designs act in different ways. Through this blog you will learn about types, functions and working principles of expansion valves.

What is the Function of the Expansion Valve?

The expansion valve can reduce the pressure and temperature of the refrigerant liquid and change its flow rate by adjusting the valve opening.

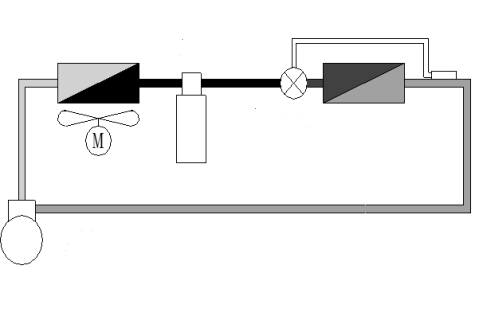

How Does Chiller Expansion Valve Work?

There is a throttle hole inside the expansion valve, and its aperture is very small, which controls the flow of refrigerant. When the high-pressure liquid refrigerant passes through the throttle hole, it will go through a process of flow rate from slow to fast. In this process, their pressure will also drop. Part of the liquid refrigerant passing will become a mixture of vapor and liquid.

For easier understanding, you can imagine the expansion valve as a high-pressure water gun. The water sprayed from the nozzle will become a mist, and their pressure and temperature will drop.

What are the Types of Expansion Valves?

1.Manual Expansion Valve

Manual expansion valves were commonly used in early mechanical refrigeration systems.As the name implies, it cannot automatically adjust the opening according to temperature changes and requires manual control. Its structure is very simple, usually consisting of a valve body, a valve needle, an adjustment button and a sealing ring. Its control accuracy depends on the proficiency of the operator, so it requires a high level of operator literacy. Moreover, its response speed is very slow, and frequent adjustments are required under complex working conditions.

2.Capillary Tube Expansion Valve

A capillary tube is a wound metal tube (usually a copper tube) with an inner diameter of 0.5mm to 2mm and a length ranging from tens of centimeters to several meters. It has a simple structure and no adjustment parts, so it cannot change the flow of the refrigerant. Because of this, it is low cost and very durable.

However, it can only adapt to a single working condition and the control accuracy is not high, so it is more suitable for use in some small equipment, such as household air conditioners, refrigerators, freezers, etc.

3.Thermal Expansion Valve (EEV)

The prototype of the thermal expansion valve was first developed by companies such as Danfoss and Emerson. Its components include throttling holes, temperature-sensing bulbs, diaphragms, springs, valve needles, etc. The diaphragm is used to compare the temperature before and after the evaporator. When the temperature rises, the expansion valve increases the opening of the valve needle to allow more refrigerant to pass through.This process does not require human. According to different balancing methods, thermal expansion valves are divided into internal balancing type and external balancing type. The external balancing type can be divided into F type and H type according to the structure.

Thermal expansion valves have low costs and high reliability due to mature technology, and occupy most of the expansion valve market. However, its sensitivity is slightly lower than that of electronic expansion valves, and it is not suitable for places with high temperature control accuracy requirements. At present, thermal expansion valves are commonly used in small and medium-sized refrigeration systems, such as cold room chillers, walk-in chamber chillers, heat pump dryers, etc.

4.Automatic Expansion Valve (AEV)

Automatic expansion valves use a spring, diaphragm and valve needle to change the flow of refrigerant.The pressure applied by the spring can be regarded as a reference pressure, which is adjustable. The diaphragm can sense the actual pressure value. The spring and the valve needle will adjust themselves according to the pressure sensed by the diaphragm, changing the opening of the valve port.

It has a relatively fast response speed, and is easy to install and maintain. However, it cannot adjust the flow rate according to the load. If the load is too large, insufficient liquid supply may occur. Therefore, the automatic expansion valve is more suitable for use when the working conditions and load are relatively stable.

5.Electronic Expansion Valve (EEV)

Since some process flows require very high temperature control accuracy, and thermal expansion valves sometimes cannot meet this requirement. Therefore, the electronic expansion valve came into being. Its main components are the valve body, stepper motor, controller, and sensor. The electronic signal sent by the sensor can control the rotation of the stepper motor, thereby changing the opening of the valve.

It has high control accuracy, fast response speed. Therefore, it is suitable for various complex working conditions and is often used in precision chillers, central air conditioners, dynamic temperature control systems, etc. However, its cost is relatively high, and its installation and commissioning are relatively complicated. There are certain technical barriers and it requires the help of professionals.

6.Float Expansion Valve

A float expansion valve senses changes in liquid level based on the height of a float, much like the float in a toilet. When the liquid level rises, the float will also rise, which will drive the valve to reduce its opening and thus reduce the flow.

Its structure is very simple,control accuracy is not high.So it is cheaper. It is more suitable for large refrigeration equipment, industrial ammonia refrigeration systems, etc.

To help you compare them, here is a comparison chart of expansion valves:

| Category | Control method | Adjustment accuracy | Response speed | Cost | Automatic adjustment |

| Thermostatic expansion valve | Superheat control | Medium-high | Medium | Medium | Yes |

| Manual expansion valve | Manual manual adjustment | Low | Slow | Low | No |

| Automatic expansion valve | Constant suction pressure | Medium | Slow | Low | Yes |

| Electronic expansion valve | Electronic controller + sensor | High | Fast | High | Yes |

| Capillary tube expansion valve | Static throttling (pressure difference) | Low | Fast | Very low | No |

| Float expansion valve | Liquid level floating control | Low | Slow | Medium-low | Yes |

Buy Equipment or Ask for a Service

LNEYA provides OEM service, we can customize the chiller for you according to your budget and application. We can provide you with an accurate quotation within half an hour at the fastest.

Recommended chillers

FLTZ -100℃~90℃

Semiconductor Chillers

Cooling capacity 0.6kW~300kW

Temp accuracy ±0.5℃

FLTZ -45℃~90℃

Multi-channel Chillers

Cooling capacity 2kW~15kW

Temp accuracy ±0.1℃

LT -80℃~30℃

Recirculating Chillers

Cooling capacity 0.4kW~17kW

Temp accuracy ±0.3℃

LTZ -115℃~90℃

Refrigeration Chillers

Cooling capacity 0.7kW~155kW

Temp accuracy ±0.5℃

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier