4 Types of Refrigeration Systems: Which One Fits Your Facility

- 4 Types of Refrigeration Systems Which One Fits Your Facility

- What is a VFD chiller VFD chiller vs Non VFD chiller

- What is a Gas Chiller

- What is a Scroll Chiller

- What is a Screw Chiller

- Chiller Refrigerant Charging Tools Steps and Tips

- Chiller Low Pressure Alarm 5 Common Reasons and Solutions

- Is r22 refrigerant still available for chillers

- August 2025

- July 2025

- June 2025

- May 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- September 2023

- July 2023

- June 2023

- May 2023

- January 2023

air cooled chiller chiller chillers Cold Assembly Freezer cooling chiller cooling heating circulator cooling heating system cooling system dynamic temperature control system freezer heating circulator industrial chiller industrial cooling industrial freezer industrial refrigerator jacket reactor low temperature chiller news reactor chiller reactor cooling reactor cooling heating reactor heating cooling refrigerated circulator screw chiller semiconductor chiller semiconductor test chiller sundi tcu temperature control test chamber thermostat ultra low temperature chiller vehicle test chiller water chiller water cooled chiller

When most people think of refrigeration, the first things that come to mind are refrigerators and air conditioners. However, refrigeration systems are practically ubiquitous. A cold warehouse full of fruit, a data center stacked with servers, the cooling loop inside a chemical plant, even the small wine cooler at home — all rely on a few core technologies.

There are four main approaches engineers use to remove heat from unwanted applications: compression systems, absorption systems, evaporative cooling, and thermoelectric setups.

Each approach is applicable to different industries and scenarios. If you’re considering which system is best for your new project, a comprehensive understanding of each will help you make the right choice.

Compression Refrigeration System

Compression refrigeration is the most common refrigeration method, widely used in direct expansion chillers and VFD chillers. It uses a compressor to compress the refrigerant, circulating it between an evaporator and a condenser, achieving cooling.

The core process of a compression refrigeration system consists of four main steps. The compressor draws in the low-pressure refrigerant gas from the evaporator, raising its pressure and temperature to prepare for heat release.

The gas then enters the condenser, releasing heat to the air and water, condensing into a liquid. As the liquid passes through the expansion valve, its pressure and temperature continue to drop.

Once it enters the evaporator, it encounters the hot coolant or air on the other side of the heat exchanger, absorbing heat from it and transforming back into a gas, which is then drawn into the compressor.

This is a highly mature and efficient refrigeration technology, so it’s used in nearly all industrial chillers, air conditioning systems, and primary cooling equipment in data centers and semiconductor chiller applications. However, there are some limitations.

Most compression chillers are electrically powered, and even those using VFD technology consume considerable energy. Furthermore, the compressor is noisy during operation, making it more suitable for installation away from living and working areas.

Absorption Refrigeration System

Unlike compression refrigeration systems, absorption refrigeration systems do not rely on electricity to drive the compressor. Instead, they use thermal energy to drive the circulation of the absorbent and refrigerant.

In the evaporator, the refrigerant absorbs heat from the environment or process, evaporating into a gas that is then absorbed by the absorbent. Common absorbents are water-lithium bromide and ammonia-water.

The solution that has absorbed the refrigerant gas enters a generator or heater, where it is heated by gas, steam, or hot water to separate the refrigerant gas from the absorbent. At this point, the gas is at high temperature and high pressure. The refrigerant gas then enters the condenser, releasing heat, liquefies, and circulates back to the evaporator. This completes the refrigeration cycle.

When introducing gas chillers, we learned that absorption chillers can use waste heat or gas for heating, and can also recover waste heat to heat process water or space heating. Therefore, energy conservation and environmental protection are significant advantages of absorption refrigeration systems.

However, compared to compression refrigeration systems, absorption chillers have a coefficient of performance (COP) and are larger, requiring more space. Therefore, absorption chillers are generally used in large cooling systems where waste heat recovery is possible, such as power plants and process cooling applications.

Evaporative Refrigeration System

As we all know, water absorbs heat from the surrounding environment when it evaporates. Evaporative refrigeration systems utilize this principle, lowering the temperature of air or liquid by absorbing heat during evaporation. They lack complex compressors and high-pressure circuits, relying instead on the flow and heat exchange structure between water and air to improve heat exchange efficiency.

Water can be evenly distributed on the surface of the object requiring heat exchange through spraying or cooling pads. When air flows over the moistened surface, the water molecules absorb heat from the air and the surface, evaporating. This lowers the air and object temperatures. Any remaining water can be recovered and recycled.

This method is limited by climate and water availability. However, it consumes very little energy and is environmentally friendly. Therefore, it is commonly used in industrial cooling towers, agricultural greenhouses, and data centers.

Thermoelectric Cooling System

A thermoelectric cooling system uses the thermoelectric effect to convert heat into cold. Its core component is the Peltier module.

When direct current passes through a Peltier module, electron flow transfers heat. The temperature on one side of the module drops, while the temperature on the other side rises.

At this point, a heat sink removes the heat from the hot side, keeping the cold side cool. A cooling plate then transfers the cold side’s temperature to the object to be cooled, achieving cooling.

This cooling method does not require mechanical components such as refrigerants and compressors, resulting in a smaller device size and suitable for space-constrained environments such as laboratories, automobiles, and medical offices.

However, the cooling power of a single module is typically only a few tens of watts, limiting cooling capacity and significantly lower efficiency than compression refrigeration systems. Furthermore, high-performance thermoelectric materials and modules are expensive.

Comparison Table of Four Refrigeration Systems

The following table provides a clear comparison of the four major types of refrigeration systems, highlighting their principles, costs, performance, and typical applications.

| Category | Vapor Compression | Absorption | Evaporative | Thermoelectric |

| Working Principle | Compressor circulates refrigerant | Heat-driven, absorbent + refrigerant cycle | Water evaporation absorbs heat | Peltier effect with DC current |

| Efficiency | Medium to high, less at part load | Low to medium, COP < compression | High, but drops in humid climates | Low, good for small-scale precise cooling |

| Energy Source | Electricity | Heat (gas/steam/waste heat) | Water + fan power | DC electricity |

| System Size | Medium to large | Large | Medium to large | Small |

| Initial Investment | Medium | High | Low to medium | Medium-high |

| Operating Cost | High electricity cost | Low if waste heat used | High water use, low power use | High electricity cost |

| Maintenance | Medium, compressor upkeep | High, solution control needed | Low, water quality issues | Low, minimal electronics care |

| Advantages | Mature, reliable, widely used | Energy-saving, uses waste heat | Eco-friendly, low cost | Precise, silent, no refrigerant |

| Disadvantages | Noisy, power dependent | Bulky, lower efficiency | Climate-dependent | Low capacity, poor efficiency |

| Typical Applications | Chillers, HVAC, data centers | Large buildings, trigeneration | Cooling towers, greenhouses, factories | Medical devices, labs, electronics cooling |

| Environmental Impact | Medium, refrigerant dependent | High, no CFCs/HFCs | High, refrigerant-free | High, refrigerant-free |

Conclusion

The most suitable refrigeration system is never the one with the best performance, but rather the one that matches your application. If you’re struggling to choose one of the four systems above, our refrigeration experts can help.

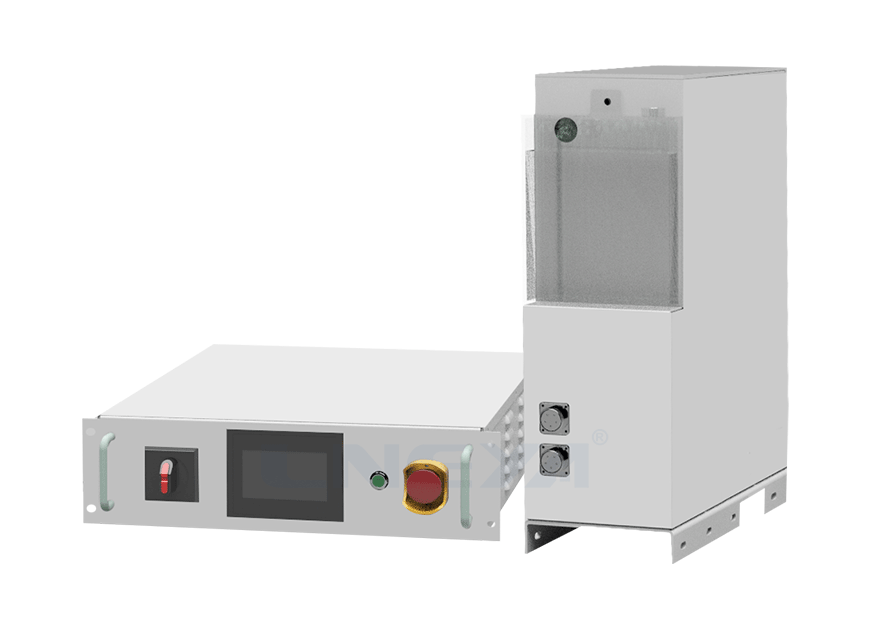

LNEYA offers a wide range of compression refrigeration equipment and Peltier cooling systems, from standard equipment to customized services. We can provide the most suitable solution tailored to your needs.

Related Chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier