What is a Scroll Chiller

- 4 Types of Refrigeration Systems Which One Fits Your Facility

- What is a VFD chiller VFD chiller vs Non VFD chiller

- What is a Gas Chiller

- What is a Scroll Chiller

- What is a Screw Chiller

- Chiller Refrigerant Charging Tools Steps and Tips

- Chiller Low Pressure Alarm 5 Common Reasons and Solutions

- Is r22 refrigerant still available for chillers

- August 2025

- July 2025

- June 2025

- May 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- September 2023

- July 2023

- June 2023

- May 2023

- January 2023

air cooled chiller chiller Chiller Installation chillers Chiller Troubleshooting Cold Assembly Freezer cooling chiller cooling heating circulator cooling heating system cooling system Double-Layer Glass Reactor dynamic temperature control system freezer gas cooling chiller heating circulator industrial chiller industrial cooling industrial freezer industrial refrigerator jacket reactor low temperature chiller news pharmaceutical chiller process chiller reactor chiller reactor cooling reactor cooling heating reactor heating cooling reactor system refrigerated circulator refrigeration chiller screw chiller semiconductor chiller semiconductor test chiller sundi tcu temperature control test chamber thermostat ultra low temperature chiller vehicle test chiller water chiller water cooled chiller wtd

This article explains the essentials of scroll chillers, from their working principles to key advantages and real-world applications.

What is a Scroll Chiller?

At its core, a scroll chiller is a packaged refrigeration system that cools a water or water-glycol loop. That chilled loop then provides cooling for air handlers, fan coil units, jacketed tanks, injection molding machines, laser systems, battery test chambers, and more.

Instead of using screw or centrifugal compressors, this machine relies on one or more scroll compressors. These are hermetically sealed, oil-filled units that compress the refrigerant in a smooth orbital motion. You’ll see two broad flavors in the field:

• Air-cooled scroll chiller: rejects heat to ambient air through condenser coils and fans. It’s easy to install outdoors, doesn’t require a cooling tower, and fits tight timelines.

• Water-cooled scroll chiller: rejects heat to a condenser water loop or cooling tower via a shell-and-tube or plate heat exchanger. It can deliver higher efficiency and stable operation in hot climates or dense urban sites.

Typical tonnage ranges run from light commercial up to mid-range industrial capacity. Where you need modularity, manufacturers stack multiple refrigeration circuits with several scrolls per circuit. That architecture gives you redundancy and a gentle stepwise response to load swings.

How Does a Scroll Chiller Work?

In a scroll chiller, the cycle starts when warm process water gives up its heat in the evaporator. The refrigerant inside boils off at low pressure and is pulled into the scroll compressor. There, the orbiting scroll squeezes the vapor smoothly, driving its pressure and temperature up.

The hot gas heads to the condenser, where it gives off heat either to outside air or to a cooling tower loop and turns back into liquid. That liquid is then throttled through the expansion valve, dropping in pressure before it re-enters the evaporator. Once it’s back in the evaporator, the process starts over, keeping the chilled water at the setpoint.

Scroll compressor

Picture two spiral scrolls that look like metal cinnamon rolls. One scroll is fixed. The other “orbits” around it without spinning on its own axis. As the moving scroll traces its path, pockets of refrigerant get trapped between the scrolls.

Those pockets spiral inward, shrinking in volume and raising the pressure and temperature of the refrigerant in a continuous, pulseless motion. No intake or exhaust valves slamming open and shut. No pistons reversing direction several times a second.

Evaporator

Warm process water (or glycol) flows through a plate heat exchanger or shell-and-tube evaporator. On the refrigerant side, low-pressure liquid flashes to vapor, absorbing heat from the fluid.

Compressor staging

With two to eight scrolls spread across one or more circuits, the controller brings compressors online as the load rises and drops. If equipped, a lead compressor with a VFD ramps speed first; fixed-speed mates follow in stages. That sequencing improves part-load efficiency and limits inrush current.

Condenser

In air-cooled units, hot gas flows to microchannel or fin-and-tube coils. Variable-speed EC fans modulate airflow to regulate condensing pressure and shave noise at night. In water-cooled units, the hot gas condenses in a water-cooled heat exchanger, and the heat heads to a cooling tower or heat-recovery loop.

Expansion device

An electronic expansion valve (EEV) meters liquid refrigerant into the evaporator, chasing a target superheat. EEVs react fast to load swings.

Explore high-efficiency and energy-saving chiller solutions!

Key Features and Advantages of Scroll Chillers

Smooth, quiet operation

Scroll compressors generate low sound power compared to other positive-displacement machines of similar size. On a roof above offices or near a lab, that matters. Low vibration also means fewer issues with piping fatigue and fewer callbacks for “odd noises.”

Modularity and redundancy

Multiple compressors across independent circuits create natural N+1 behavior. Lose one compressor and the rest carry part of the load. During maintenance, you can keep one circuit running while the other is down. Plants that can’t afford a full shutdown value that flexibility.

Strong part-load efficiency

Most real systems don’t run at 100% all day. They loaf at 30–70% for long stretches. Staged scrolls shine here, and with a variable-speed lead scroll, the efficiency curve bends even better at low load. Your energy bills reflect that, especially in mild climates.

Compact footprint and easy install

Air-cooled scroll packages ship as one skid with pumps optional. Set the pad or steel, land power, run chilled-water piping, and you’re close. Water-cooled versions tuck into mechanical rooms with tight clearances.

Predictable maintenance

Scrolls are hermetic. There’s no shaft seal to chase. Routine service centers on coils, filters, water treatment, and electrical checks. Oil stays in the circuit; with sound piping design, you won’t be fighting oil return. Electronic controls provide trend logs and alarm history, so troubleshooting is faster.

Good temperature stability

With a buffer tank sized to your load swings, you can hold narrow bands even when a process is cycling. Hot-gas bypass can protect against short cycling on tiny loads, though modern variable-speed control often makes bypass unnecessary.

Refrigerant choices and compliance

Many models use familiar blends like R410A today, with a growing shift to lowe-GWP options such as R32 or R454B where codes allow. The scroll system adapts well to these refrigerants, and manufacturers offer charge-limiting designs and leak detection to align with safety standards.

Applications of Scroll Chillers

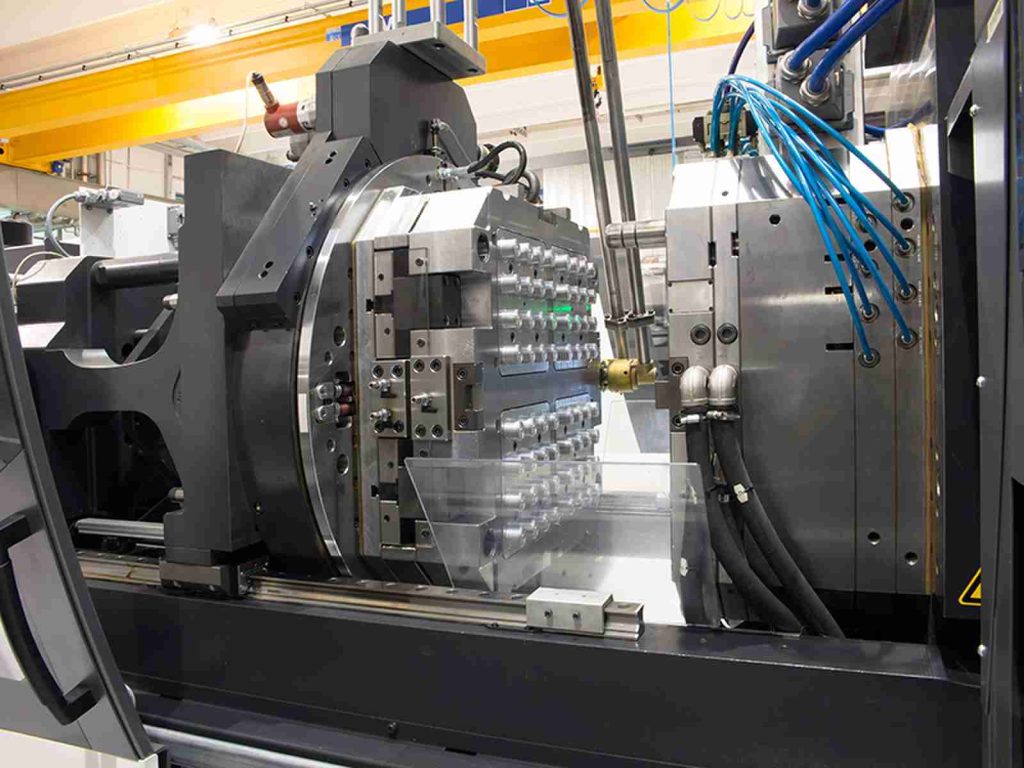

Plastic injection and extrusion

Mold temperature is king. An air-cooled scroll chiller with a glycol loop and a buffer tank gives steady leaving water even as molds change and cycle times vary. Multiple circuits help because different presses rarely peak together.

Laboratories and life sciences

Glass washers, environmental rooms, and laser cooling all benefit from low noise and stable temperatures. When the roof is right over occupied space, the quiet behavior of scroll compressors becomes an immediate win. Low-ambient kits keep air-cooled units operating on winter mornings without nuisance trips.

Breweries and food process

Fermentation, crash cooling, and jacketed tanks need dependable coolant at setpoint. A packaged industrial scroll chiller with stainless plate exchangers, a sanitary pump skid, and outdoor-rated controls checks all the boxes. The modularity lets you expand capacity as the brew house grows.

Data rooms and edge facilities

Not every site is a multi-megawatt data center. Edge racks in warehouses and campus buildings need chilled water with high uptime. Multiple circuits give failover, and swappable compressor modules speed repairs. Tie it to your monitoring stack and you’ll know about temperature drift before users do.

Conclusion

Looking for the right scroll chiller for your new project? LNEYA offers a variety of standard scroll chillers and custom services. Contact our chiller experts to discuss your temperature control needs.

Related Chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier