Environmental Conditions for Installation of Air Cooled Chillers

As we all know, the installation of most machines needs to match the environment and conditions. Of course, our industrial air-cooled chillers are no exception. If the air-cooled chiller is not installed for the first time, it will bring a lot of inconvenience and loss to the later industrial production! For example, if the chiller is not installed smoothly, it will cause abnormal operation of the chiller, resulting in noise, water leakage and even having to shut down for maintenance. It may also cause poor heat dissipation of air-cooled chiller and affect the refrigeration effect, resulting in equipment failure. So what basic conditions need to be met for the installation of air-cooled chillers? Let’s have a look.

Three basic conditions for installing industrial air-cooled chillers:

1. Choose a safe installation environment.

Due to the high temperature phenomenon during the operation of industrial chillers, it is necessary to keep away from all kinds of flammable and explosive substances in order to improve the operation efficiency of industrial chillers. In addition, many environments with high radiation also do great harm to chillers. In order to prolong the service life of industrial chillers, appropriate installation environment must be selected.

2. Select the installation environment with good light.

The maintenance of industrial chillers is essential. Therefore, in order to ensure a good maintenance line of sight in the later stage, it is necessary to select a place with good and bright light for employees to inspect and maintain in the later stage.

3. Select the installation environment with low ambient temperature and good ventilation.

Industrial chillers will produce more heat in the process of use. In order to maintain the stability of the industrial chiller, it is necessary to select a place with low temperature and good ventilation for installation, so that the chiller can dissipate heat in time. Especially for air-cooled chillers, air circulation has an important impact on improving the overall working efficiency of chillers. The room temperature shall be lower than 40 ℃ as far as possible, and the ventilation shall be good. If the temperature is 40 ℃, the ambient relative humidity must be lower than 90%. Do not install and store outdoors or outdoors.

The above contents, that is, the installation of industrial air-cooled chiller shall meet certain basic conditions. The installation of industrial water chillers is a very important thing, so we should pay attention to it. As mentioned above, only when our chiller installation meets these conditions can we effectively ensure the safe and stable operation of the chiller and facilitate later inspection and maintenance. Otherwise, due to the wrong installation environment, it brings problems to the later use, which is not worth the loss.

Related recommendations

-

Simulation analysis and result analysis of battery pack thermal management

1593battery pack thermal management simulation analysis

View details -

Instructions to Use Industrial Cryogenic Refrigerator

1743Industrial refrigerators are one of the cold water machines. It is classified according to the cooling mode of the cold water machine itself. It is divided into air cooling type refrigerators and water cooled refrigerators. Structural features: a ...

View details -

Battery pack cooling water machine Chiller use precautions

1538The battery pack cooling water machine Chiller is used for the new energy battery pack cooling system. The user needs to pay attention to avoid misuse during operation, which causes the battery pack cooling and circulating water machine Chiller to...

View details -

High temperature silicone oil cooling and heating cycle machine maintenance steps

1441The mechanical wear of the high temperature silicone oil cooling and heating cycle machine is an important factor that directly affects the refrigeration capacity. It is necessary to record the operating parameters during use, often listen to the ...

View details

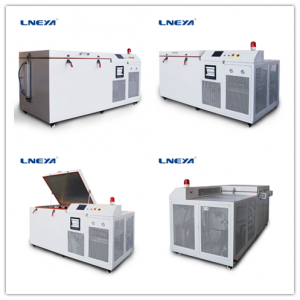

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier