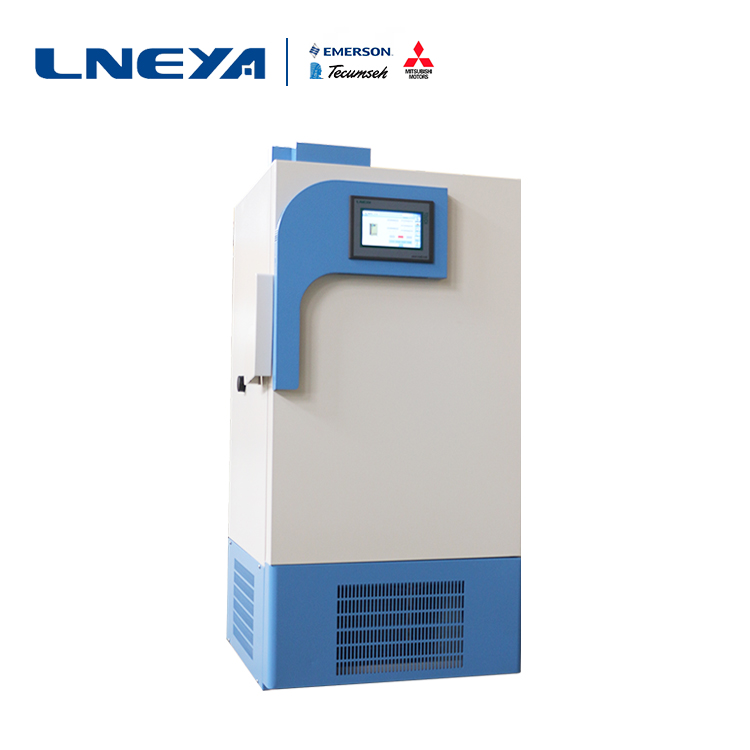

LNEYA ultra-low temperature cold box power supply+electronic control instrument system description

LNEYA ultra-low temperature cold box needs to be tested after a long time of use. What should be paid attention to when the power supply and electronic control instrument system are inspecting?

LNEYA ultra-low temperature cold box power supply and electronic control instrument system inspection, before power-on should check whether the distribution capacity and unit power are consistent, whether the selected cable diameter can withstand the host operating current. Check whether the electrical system is consistent with the unit. The unit is electrically: three-phase five-wire system (three phase lines, one neutral line, one ground line, 380V ± 10%). Check if the power supply line of the compressor is connected tightly. If it is loose, retighten it. The torque at the compressor wiring is 500kg/cm. Due to factors such as long-distance transportation and lifting, the screws may be loose. Failure to do so may result in damage to electrical components (such as air switches, AC contactors, etc.) and compressors in the main control cabinet.

Use a multimeter to carefully inspect all electrical circuits of the LNEYA ultra-low temperature cold box, check that the wiring is properly installed in place; use megaohm measurement to make sure there is no short circuit in the case; check that the ground wire is properly installed in place, and the insulation resistance to ground is greater than 2MΩ; check if the power cable is Meet the capacity requirements. Check if the disconnect switch is installed on the power supply line of the supply unit. All the wiring of the main circuit in the control cabinet and the external wiring of the control circuit can be energized after comprehensive inspection (such as crankcase oil heater, compressor electronic protector, circulating water temperature sensor, target flow switch wiring, pump connection) Control, etc.); Check if the terminal bolts are tightened and there is no looseness.

The performance of the power supply and the electronic control instrument are more important in the operation of the LNEYA ultra-low temperature cold box, so it is necessary to check the recommendations regularly.

Related recommendations

-

Bioreactor temperature rise and temperature control equipment

1343A bioreactor is a reaction system in which a naturally occurring microorganism or a microorganism having a special degrading ability is inoculated into a liquid phase or a solid phase. The two reactors currently studied the most are "elevator type...

View details -

Performance description of recirculating chiller for bioreactor

1565The recirculating chiller is suitable forthe high and low temperature reaction of various stainless steel, enamel,titanium alloy reactors, emulsifiers, injection molding machines, mixingvessels and various bioreactors. Other bioreactors in diff...

View details -

TCU temperature control model selection and technical parameter description

2105TCU temperature control is also a two-cycle unit single-fluid temperature control system. When selecting the model, it is very important for the whole temperature control reaction. Only the appropriate reaction system is used to exotherm and absor...

View details -

LNEYA PCR microfluidic chip temperature control system project development objectivity

1613The PCR microfluidic chip temperature control system is a new dynamic refrigeration heating produced by LNEYA for the integrated circuit chip industry. For the chip testing industry, the LNEYA PCR microfluidic chip temperature control system can b...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier