Application area of high temperature refrigeration and cooling control system

The high-temperature refrigeration and cooling control system is used for supporting glass reactors, rotary evaporators, fermentation tanks, and calorimeters; widely used in petroleum, chemical, metallurgical, biochemical, physics, testing and chemical analysis research departments, universities, and factory experiments Laboratory and metrology quality inspection department. The high-temperature refrigeration and cooling control system can provide cooling circulating water to cool the equipment or provide heat for heating according to the production requirements, and at the same time, the temperature can be kept constant between ±2°C.

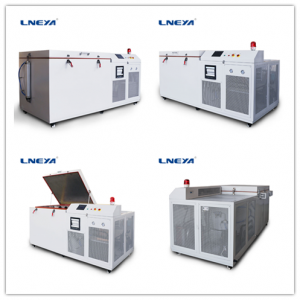

The high-temperature refrigeration and cooling control system can be used for heating and cooling, and can also realize mutual switching to speed up production progress and reduce energy consumption, improve product molding efficiency, and reduce the production of defective products. Computer touch control, automatic calculation model, multi-point temperature control unit can be customized. The temperature can be automatically controlled, and the set temperature can be reached quickly, and the set value and actual value are displayed separately. Isolated electrical control box, extend the service life of electrical appliances, pipeline explosion-proof device, built-in safety protection, low noise, high temperature and corrosion resistance, unique heating design, power saving and durable, suitable for use in different temperature control places.

The high-temperature refrigeration control system is a laboratory instrument with dual functions of heating and cooling. This instrument adopts a number of proprietary technologies and has high temperature control accuracy. It is mainly used in biological, chemical and other fields (such as rotary evaporators, reactors, fermentation tanks) , Calorimeter and other equipment); this instrument is highly automated and can automatically heat or cool according to set requirements; this type of temperature control equipment has universal heating and cooling functions and can meet the needs of various biochemical experiments.

The design and component parts of the refrigeration circuit of the high temperature refrigeration and cooling control system are particularly important for the control of the mold temperature. When the temperature of the mold or heating fluid rises to the set value, it can quickly and effectively prevent the temperature from continuing to rise. Therefore, according to different customers, the instructions are different, because it can be customized according to the needs of different customers.

Related recommendations

-

Analysis of the reasons for non-refrigeration of cryogenic refrigeration equipment

1058Ultra-low temperature refrigeration equipment is mainly used in industrial cold processing. Unlike some manufacturers of ultra-low temperature refrigeration equipment, LNEYA ultra-low temperature refrigeration equipment uses environmentally friend...

View details -

What are the influences on the refrigeration factors of the enclosed explosion-proof chiller?

1019Check if it is the cause of the failure of the enclosed explosion-proof chiller. This selection must be accurate. If the model is not in place, the required cooling effect will not be achieved. It is recommended that the user will need it when pur...

View details -

Temperature control system for controlling integrated circuit chip test temperature

1046Advances in semiconductor technology have led to the development of next-generation electronic devices such as integrated circuits, which have more and more active components, higher circuit complexity, smaller area, and tighter wiring. These attr...

View details -

The savior of the cannabis extraction industry cannabis oil chiller | CBD chiller

1069The hemp, cannabis, and CBD/THC industry is taking off. Efficient and effective equipment is required to maintain the quality of CBD and THC oils. Oils can go rancid and break down without proper preservation. Re-outfitting a refrigerator or alcoh...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier