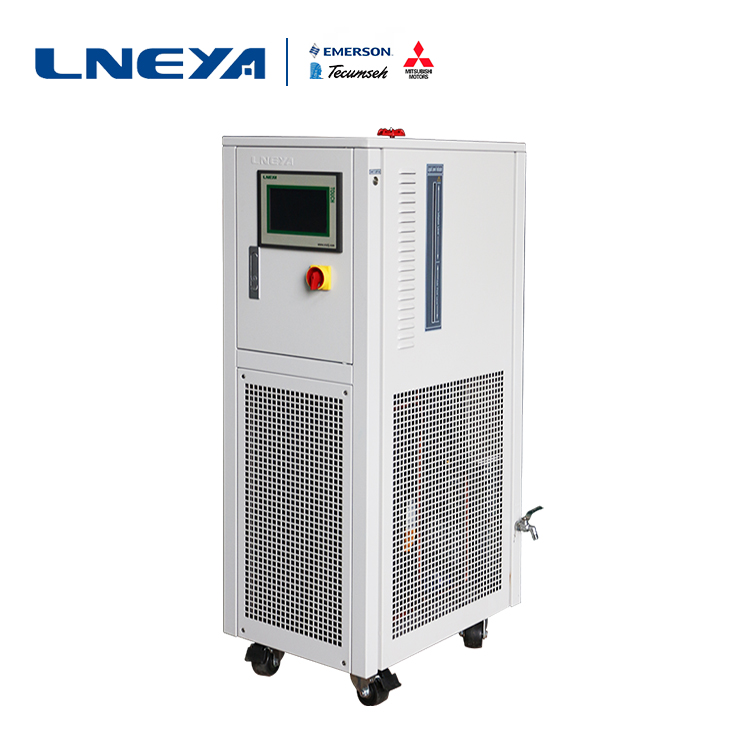

Closed hot and cold cycle machine compressor fault repair process

LNEYA’s closed-type hot and cold cycle machine adopts single-machine self-cascading refrigeration technology, and its compressor also uses the brand compressor, which is more stable in performance. Therefore, it is easy to choose a series of compressors with general performance. malfunction.

If the screw compressor is used in the closed type hot and cold cycle machine, the operation and maintenance process is very simple. Before the screw compressor of the closed type hot and cold cycle machine must be overhauled, if possible, the slide valve is unloaded to the “0” position. , normal shutdown, cut off the power. The compressor can be disassembled by cutting off the piping connected to the compressor and discharging the refrigerant and lubricating oil in the compressor. Be careful to develop good habits when disassembling. Parts of different parts should be placed separately and the necessary assembly marks should be made.

After removing the pipes, couplings and anchor bolts connected to the compressor of the closed type hot and cold cycle machine, the compressor is lifted to the workplace. Remove the suction filter, suction check valve, and remove the energy indicator. Remove the locating pin, remove the suction end cap in parallel, and take out the oil piston and balance piston. Note that when the positioning pin is taken, it can only be pulled out and cannot be pulled out. Be sure to take out the positioning pin first, then remove all the bolts to prevent the weight of the suction end cover from acting on the positioning pin and bend the positioning pin. Remove the shaft cover and remove the shaft seal. Be careful not to touch the moving and stationary rings, remove the positioning pin, remove the exhaust end cap, and remove the bearing gland, lock nut, washer, thrust bearing, adjusting pad, etc. To remove the locknut, use a special special tool and first open the lock tab of the lock washer. Mark them at any time and place them separately. After removing the compressor positioning pin, remove the exhaust end seat and use the special eye bolt to slowly and smoothly remove the active rotor, and do not collide with the body. At this time, the driven rotor rotates accordingly, and the driven rotor is taken out and the spool is taken out.

Wuxi Guanya (LNEYA) closed type hot and cold cycle compressor adopts Hanzhong, Bitzer, Copeland, Danfoss and other brands, and its performance is reliable. It is suitable for refrigeration, chemical and other industries, and has been highly praised by users.

Related recommendations

-

What are the conditions for the decarboxylation reaction? How to control the temperature of heating?

1835The decarboxylation of aromatic acids is easier than that of fatty acids. For example, benzoic acid can be decarboxylated by adding a little copper powder as a catalyst in quinoline solution and heating. When a strong electron-withdrawing group i...

View details -

How To Solve The Electric Vehicle Motor Test Condensation Is Too High?

1700The condensing pressure of the electric vehicle motor test will increase, the compression function will increase, the cooling capacity will decrease, the cooling coefficient will decrease, and the energy consumption will increase. The reason for t...

View details -

How to deal with the excess refrigerant in 3p freezers?

1695When the three freezers are being serviced, it is necessary to add refrigerant regularly, but the manufacturer of LNEYA reminds everyone that once the refrigerant is added excessively, it will cause a series of problems. According to the instructi...

View details -

Hash water quality analyzer chiller

1341Hash water quality analyzer often requires precise temperature control when performing water quality analysis to ensure the accuracy and reliability of the measurement results. Chillers are one of the important devices that provide thi...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier