Cooling and heating temperature control system supporting glass reactor temperature control

my country’s chemical industry has developed rapidly, and many enterprises have accelerated their stable development. In the chemical industry, the refrigeration heating temperature control system is matched with a glass reactor to control the reaction temperature.

The cooling and heating temperature control system combined with the glass reactor is an ideal teaching and experimental temperature control equipment for modern fine chemicals, biopharmaceuticals and new material synthesis. The cooling and heating temperature control system is matched with the biochemical instruments commonly used in glass reactors, which are widely used in modern fine chemical industry, biopharmaceuticals, scientific research and experiments and other industries. Retention, separation and purification reaction.

In the production process, whether it is a double-layer glass reactor or a single-layer glass reactor, the cooling and heating temperature control system and the glass reactor can generally complete high temperature, low temperature and vacuum reaction experiments at the same time. Under constant temperature conditions, in a closed container, the cooling and heating temperature control system and glass reactor can be stirred and reacted under normal pressure or negative pressure, and the evaporation and reflux of the reaction solution can be controlled. Under high temperature conditions, the cooling and heating temperature control system can be used for chemical and chemical reactions with glass reactors. In addition, for different performance structures and heating methods, the reactor also has steam heating, water heating, electric heating and other options.

Steam Heating Method:

When the cooling and heating temperature control system is matched with the glass reactor production and the heating temperature is required to be below 100 °C, the method of heating the glass reactor with steam can be used. This method uses steam below one atmosphere to heat the device. When the temperature is required to be in the range of 100-180 °C, saturated steam can be used; when the temperature is required to be higher, high-pressure superheated steam can be used for heating.

Electric Heating Method:

Electric heating is wound on the insulating layer of the glass reactor barrel through resistance wires, or installed on a special insulator at a distance from the glass reactor. Therefore, a small gap can be formed between the resistance wire and the glass reactor body.

Water Heating Method:

When the temperature requirement is not high in the production process, water heating can be used for heating. There are two types of water heating systems: open and closed. The open type is relatively simple. It consists of a circulating pump, a water tank, a pipeline and a regulator that controls the valve.

The above three methods are relatively common heating methods. LNEYA uses heat-conducting oil as the medium and a fully-closed circulating pipeline system, which avoids the generation of oil mist during high-temperature heating, no pungent odor, and no heat-conducting medium. Discoloration; it also prevents the heat transfer medium from becoming viscous and sticking to the wall of the reactor after absorbing moisture, reducing the heat transfer effect.

Summarize:

It should be reminded that each enterprise has different heating methods for cooling, heating and temperature control systems with glass reactors, as well as different production process requirements. Therefore, purchasing enterprise users need to purchase according to their actual needs.

Related recommendations

-

Purchasing a special chiller for etching machine and precautions for operation

1055The special chiller for etching machine is used for testing of components, chips, etc. These industries are more supporting use, so what aspects should be paid attention to when choosing the chiller for etching machine drilling? What should I pay ...

View details -

Necessity Of New Energy Electric Vehicle Battery Test System

875The battery performance of new energy vehicles directly determines the experience of new energy vehicle end users. The electric vehicle battery test system needs to test the performance reliability of new energy vehicle batteries. With the develop...

View details -

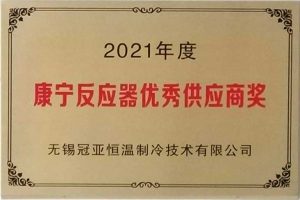

Won the “Excellent Supplier of Reactor Temperature Control Equipment in 2021”

3002LNEYA was awarded the "2021 Excellent Supplier of Reactor Technology" by Corning, a Fortune 500 company in the United States. Since 2015, LNEYA has won this award for 7 consecutive years. Therefore, in the reactor manufacturing industry, we have ...

View details -

How to deal with the excess refrigerant in 3p freezers?

1094When the three freezers are being serviced, it is necessary to add refrigerant regularly, but the manufacturer of LNEYA reminds everyone that once the refrigerant is added excessively, it will cause a series of problems. According to the instructi...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier