Necessity Of New Energy Electric Vehicle Battery Test System

The battery performance of new energy vehicles directly determines the experience of new energy vehicle end users. The electric vehicle battery test system needs to test the performance reliability of new energy vehicle batteries. With the development of technology, its requirements are also higher. .

With the continuous development of new energy applications, the performance of power batteries for new energy vehicles has received extensive attention. Therefore, testing the ability to evaluate power batteries and portable lithium batteries, providing safe and reliable batteries is particularly important in the development of new energy vehicles and consumer electronics.

The electric vehicle battery test system includes basic performance, cycle performance and safety performance. The battery performance requirements for different applications are different, and the test content of portable lithium battery and power battery will be more or less. Power batteries are more demanding than portable lithium-ion batteries. Therefore, in terms of basic performance, in addition to battery core charge and discharge, battery capacity and internal resistance test, battery pack/module charge and discharge performance and internal resistance are also required. test. In terms of safety performance, in addition to conventional battery cell temperature detection and battery safety monitoring, it is also necessary to test the battery pack/module temperature, BMS communication and VCU simulation of the power battery.

We all know that electric vehicle battery test system in the actual battery test experiment, the conventional test program will have some drawbacks, including long test time, and no equivalent test method can compress the test time; there will be battery leakage when testing battery safety performance Risk of explosion or the like; it is impossible to provide repetitive test results, and it is difficult to reproduce the fault when the test test fails.

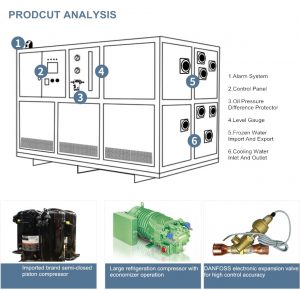

In order to solve these problems, Wuxi Guanya LNEYA proposed a new solution – electric vehicle battery test system, testing hybrid vehicles, pure electric vehicles, hydrogen engine vehicles, fuel cell electric vehicles, extended-range electric vehicles, other new energy vehicles Medium-precision permanent magnet synchronous motor, switched reluctance motor, asynchronous motor and its controller are tested with precision temperature control equipment. The main parts are all international brands and quality assurance.

At present, Wuxi Guanya LNEYA electric vehicle battery test system can test new energy vehicle batteries and motors, and establish a new battery temperature control test system.

Related recommendations

-

Energy storage system requirements for temperature-controlled liquid-cooled unit

1988Energy storage system: It needs to meet the discharge demand for a long time. It is suitable for energy storage on the side of new energy generation, arbitrage of peak-valley price difference on the user side, etc. The future trend is that...

View details -

Industry and introduction of low temperature chiller

1437In petroleum refining, petrochemical industry, organic synthesis, chemical products and other industrial production, refrigeration technology must be applied to control the reaction temperature during processes such as liquefaction, condensation, ...

View details -

How to Prolong the Service Life of Glycol Chiller System?

1497In order to extend the service life of your glycol chiller in industrial applications, please pay attention to the following points: 1. Use automobile grade antifreeze carefullyDo not use automobile grade or unqualified antifreeze. Because this gl...

View details -

Simulation control of temperature change in the cooling and heating temperature control system of th

1284Industrial cooling and heating temperature control system is a temperature control equipment used in the cooling and heating process of reaction kettle in the pharmaceutical and chemical industry. What are the characteristics of lneya's equipment?...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier